New Video -Cyanide Carbon Leaching Process

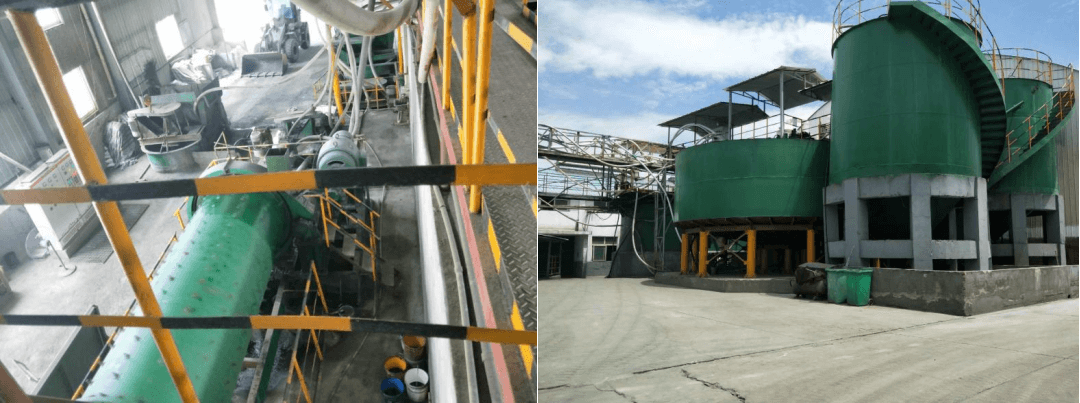

In the realm of gold extraction, the cyanide carbon leaching process has emerged as a dominant method. This process involves a series of steps, each crucial to the efficient recovery of gold from ore. Let’s delve into the details.

Process Overview

The cyanide carbon leaching process typically consists of four primary stages:

- Crushing and Grinding: The ore is reduced to a fine particle size to enhance the exposure of gold particles to the leaching solution.

- Leaching: A cyanide solution is used to dissolve gold from the ore.

- Activated Carbon Adsorption: Activated carbon is added to the solution to adsorb the dissolved gold.

- Gold Recovery: The gold is recovered from the activated carbon through a process called elution.

CIL vs. CIP

The leaching and adsorption steps can be combined in two different ways:

- CIL (Carbon-in-Pulp): Activated carbon is added directly to the leaching tanks, allowing for simultaneous leaching and adsorption.

- CIP (Carbon-in-Column): The ore is leached first, and then the solution is passed through columns containing activated carbon.

Advantages of Cyanide Carbon Leaching

- High Recovery Rates: This process boasts impressive gold recovery rates, often exceeding 90%.

- Versatility: It can be applied to a wide range of gold ores.

Economic Considerations

While the cyanide carbon leaching process offers excellent results, it’s important to note that it comes with a higher cost compared to traditional methods like gravity and flotation separation.

Conclusion

The cyanide carbon leaching process has become a cornerstone of the gold mining industry. Its ability to efficiently extract gold from various ore types has made it a preferred choice for many mining operations. However, the economic factors associated with this process must be carefully considered.

We can provide you with more information about the cyanide leaching plant. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]