How to Optimize Heap Leaching for Gold and Silver Extraction?

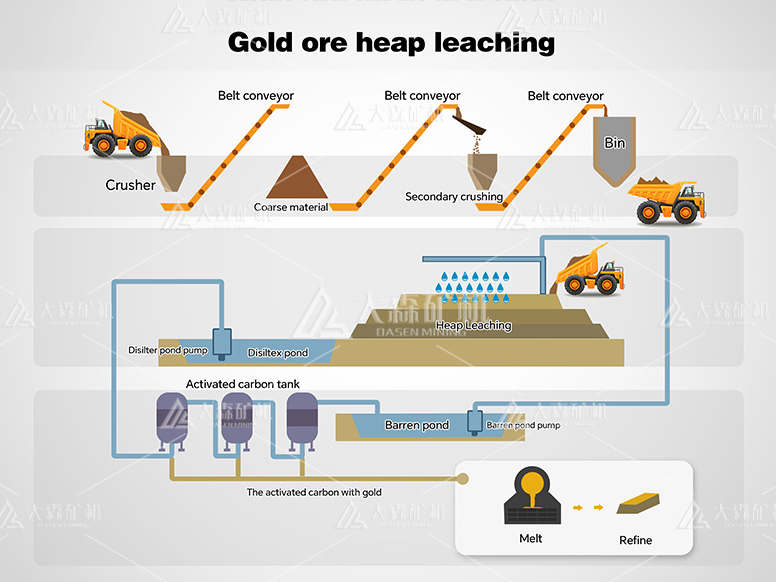

Heap leaching is a widely used method for extracting precious metals like gold and silver from low-grade ores. It involves creating a heap of crushed ore and spraying it with a leaching solution, typically containing cyanide. To ensure efficient extraction, several key factors must be considered.

Pre-Leaching Treatment

Before applying the cyanide solution, the ore heap should be thoroughly washed with water and alkali. This pre-treatment helps to remove impurities and create a more favorable environment for gold and silver dissolution.

Cyanide Solution Application

pH Adjustment: The pH of the leaching solution should be maintained between 9.5 and 11. This alkaline environment enhances gold and silver solubility.

Spraying Equipment: The cyanide solution should be sprayed evenly over the ore heap. Proper liquid distribution is crucial for maximizing extraction rates.

Spray Intensity: The spray intensity should be adjusted based on the ore heap’s size and permeability. A higher intensity may be required for larger or less permeable heaps.

Leaching Process Parameters

Cyanide Concentration: The concentration of cyanide in the leaching solution should be controlled within a specific range, typically 0.02 to 0.1%.

Oxygen Supply: Adequate oxygen supply is essential for the oxidation of gold and silver. Intermittent spraying can help introduce oxygen into the heap.

Leaching Time: The leaching time depends on the ore properties and particle size. It can range from 1 to 3 months.

Gold and Silver Recovery

Once the leaching process is complete, the pregnant leach solution (PLS) containing dissolved gold and silver is collected and processed to recover the precious metals. Common recovery methods include:

Carbon Adsorption: The PLS is passed through activated carbon columns, which adsorb the gold and silver.

Zinc Precipitation: Zinc metal is added to the PLS to precipitate gold and silver.

Electrowinning: Gold and silver are recovered through electrolysis.

Whatsapp:+86 133 1927 7356

Email:[email protected]