How does particle size affect a centrifugal concentrator?

In the world of gold mining, achieving optimal recovery rates is paramount. One of the key factors that significantly influences the performance of a centrifugal gold concentrator is the particle size of the processed minerals. Today, I’d like to delve into how mineral particle size affects the efficiency of centrifugal gravity concentrators and why it’s crucial for maximizing gold recovery.

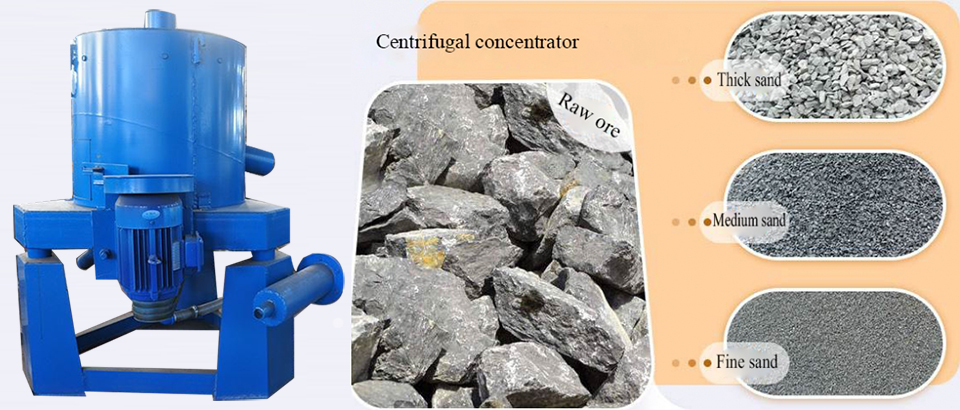

The Role of Particle Size in Centrifugal Separation

Centrifugal separation relies on the difference in specific gravity between valuable minerals and gangue (waste material). While complete mineral liberation isn’t always necessary, achieving a certain degree of dissociation is crucial. Without this, gangue and minerals can compete during settling, leading to suboptimal separation results.

Test Results: The Evidence

Let’s examine two sets of test results to illustrate the impact of particle size on centrifugal concentrator beneficiation:

1.Full Particle Feeding (No Sieving):

Lead Grade Before Separation: 1.11%

Lead Grade After Separation: 5.45%

Enrichment Ratio: 4.91 times

Recovery Rate: 37.85%

2.Two-Stage Sieving (100 Mesh):

First Stage (100 Mesh Feed):

Lead Grade Before Separation: 1.09%

Lead Grade After Separation: 2.87%

Enrichment Ratio: 2.63 times

Recovery Rate: 18.83%

Second Stage (-100 Mesh Feed):

Lead Grade Before Separation: 1.42%

Lead Grade After Separation: 8.35%

Enrichment Ratio: 5.88 times

Recovery Rate: 50.10%

From these results, it’s clear that particle size significantly impacts the performance of a centrifuge for gold recovery. The first group, with full particle feeding, showed a moderate enrichment ratio and recovery rate. However, the second group, which was sieved into two stages, demonstrated a stark difference. The upper stage (100 mesh) showed poor dissociation and separation, while the lower stage (-100 mesh) exhibited excellent beneficiation indices.

This comparison underscores the importance of determining the optimal particle size for centrifugal separation. Through comprehensive particle size testing, miners can identify the best separation particle size for their specific ore, thereby maximizing the efficiency of their centrifugal gold concentrators.

Why Choose Dasen?

At Dasen, we provide professional ore testing, expert analysis, and detailed reports to help you optimize your gold recovery process. Our specialists are dedicated to ensuring you achieve the highest possible recovery rates with our centrifugal gravity concentrators.

Whatsapp:+86 133 1927 7356

Email:[email protected]