Gold heap leaching operation in cold weather

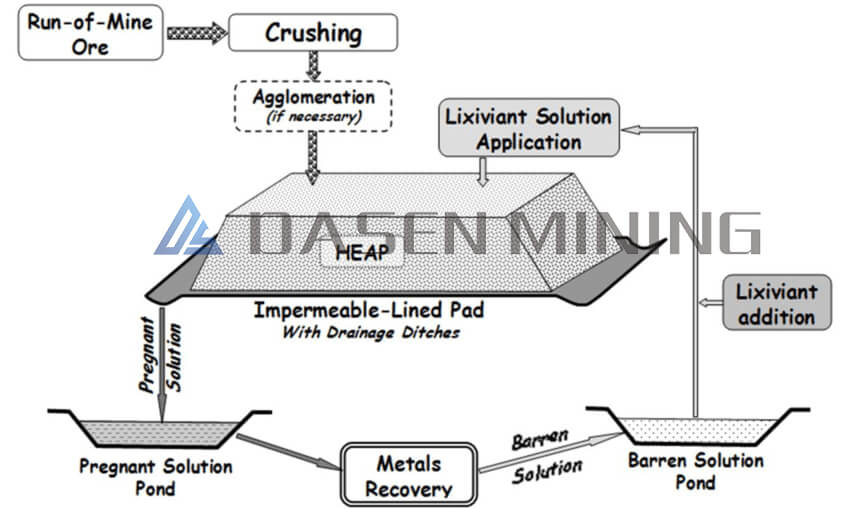

Gold heap leaching operations are highly dependent on the climate and environmental conditions of the mining area. In tropical regions, operations can continue year-round, with the only caveat being the need to avoid the plum rain season to prevent waterlogging, which can adversely affect the leaching process. In subtropical areas, the optimal leaching period typically spans from March to November. However, the question arises: how do we approach cyanide heap leach mining in polar regions, where the climate is far more challenging?

For most mining operations, input costs are a primary concern. The profitability of cyanide heap leach mining is not solely determined by the profit per ton of ore but is significantly influenced by the processing capacity of the mine. Therefore, it is crucial to consider the cost per ton of ore processed. In colder regions, a common strategy is to conduct construction and stacking during the winter months and commence leaching in other seasons when conditions are more favorable. This approach helps in improving gold recovery rates. In extremely cold regions, careful planning and preparation can extend the operational window by a month or two, which can significantly enhance the overall recovery of the gold mine.

Overcoming Low-Temperature Challenges

As technology and operational practices have advanced, cyanide heap leach mining has expanded into progressively colder regions. A key challenge in these environments is the freezing of the leaching solution, which can render pumps inoperative and slow down the reaction of the leaching agent. The formation of an ice layer on the heap’s surface, due to common spraying techniques, further inhibits leaching by preventing the solution from penetrating the ore.

To address these issues, several methods have been developed:

1.Heating the Solution: One effective method to prevent ice formation on the pile’s surface is to heat the solution. A submerged combustion heater, known for its high thermal efficiency, can be used. This method economically heats the circulating solution but can lead to increased carbon dioxide dissolution in the alkaline solution, exacerbating pipeline fouling. To mitigate this, a heat exchanger can be installed as an alternative, which has proven to be successful.

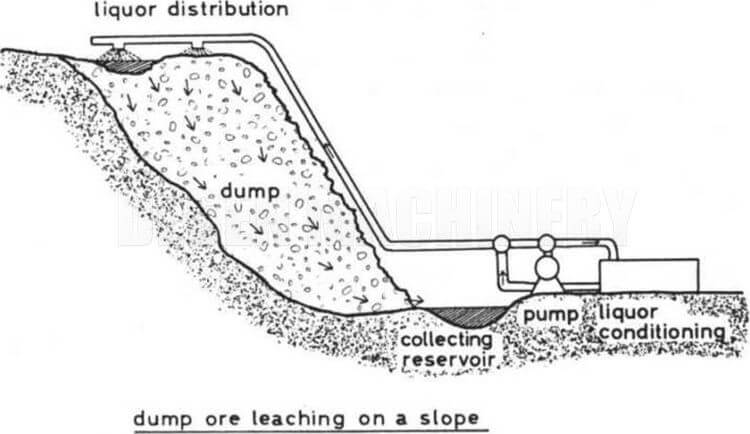

2.Buried Irrigation: Another approach is to install an irrigation system beneath the pile’s surface and cover it with enough ore to prevent freezing. When the weather warms up, the ore cover is sprayed from above to leach the top material.

In extremely cold areas, such as parts of Russia, where the time window for cyanide heap leach mining is very limited, careful planning and rapid processing are essential. Despite these challenges, one of our clients has successfully operated a heap leaching plant for oxide gold, achieving a leaching rate of 68%. This success is attributed to meticulous planning, preparation, and effective management.

If you have ideas or questions about heap leaching of gold mines, please contact us: Whatsapp:+86 133 1927 7356

Email:[email protected]