Which Flotation Techniques Maximize Copper Yield in Oxide Ore Beneficiation?

Cuprite is an oxide mineral characterized by its low hardness, high density, and distinctive red color. It is formed through the weathering of copper sulfide and typically exhibits a high ore grade. The copper flotation process is the most widely used beneficiation technique for cuprite ores. The primary recovery methods include conventional sulfide flotation, hydrothermal sulfide flotation, and fatty acid flotation.

Copper plays a vital role in economic development, with applications spanning power transmission, communication cables, motor manufacturing, integrated circuits, energy petrochemicals, and various transportation sectors like ships, automobiles, airplanes, and railways. As the availability of easily exploitable copper sulfide resources declines and the demand for copper continues to rise, attention has shifted towards more challenging cuprite-type copper oxide ores, which can contain up to 85% copper.

1.Sulfide Flotation Method

In the conventional sulfide flotation process, sodium sulfide or sodium hydrosulfide is used to sulfide the ore, followed by the use of xanthate as a collector. The efficiency of this method is influenced by the pH value of the pulp; a lower pH accelerates the vulcanization rate. However, a significant drawback is the tendency of vulcanizing agents like sodium sulfide to oxidize and lose their effectiveness. To mitigate this, the vulcanizing agent should be added in batches during the copper flotation process.

2.Hydrothermal Sulfide Flotation Method

This method is an improvement over conventional flotation. It involves heating sulfur to induce a reaction with the ore, forming copper sulfide minerals that are then recovered in warm water. While this process enhances pre-sulfurization and flotation in warm water, it presents challenges such as high temperature requirements, significant fuel consumption, and lengthy reaction times, making large-scale implementation difficult.

3.Fatty Acid Flotation Method

Also known as the direct flotation method, this technique uses fatty acids and their soaps as collectors. However, it has limitations and is often supplemented with sodium sulfide and xanthate in foreign concentrators. In some cases, it may be more effective to switch directly to sulfide flotation. This method is suitable for treating sulfide-oxidized mixed ores with carbonate gangue. During flotation, sulfide minerals are floated with xanthate, and the tailings are then floated out with fatty acid.

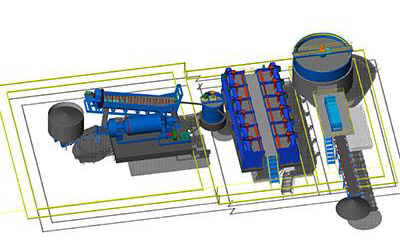

Essential Flotation Equipment

Flotation machines are crucial for any chosen treatment method. These machines thoroughly stir and aerate the pulp, causing ore particles to selectively adhere to bubbles, float to the surface, and be skimmed off for mineral separation. Flotation machines can be categorized into mechanical stirring, aerated stirring, and inflatable types.

1.Mechanical Stirring Flotation Machine: Relies on impellers and other mechanical components to stir the slurry, functioning as an external air self-suction flotation machine.

2.Aerated and Stirred Flotation Machine: Equipped with both a mechanical stirring device and a special fan to force air in.

3.Inflatable Flotation Machine: Lacks a mechanical stirring device and relies on air provided by a special compressor.

Dasen Mining provides insights into the copper flotation process and the main equipment used for copper ore flotation. While cuprite ores are rich in resources and high in copper content, they are also challenging to sort. Therefore, selecting the appropriate flotation method and equipment is essential for efficient beneficiation.

you can contact:Whatsapp:+86 133 1927 7356

Email:[email protected]