How Does 98% Sodium Cyanide Boost Efficiency in Niger’s Gold Cyanide Plant?

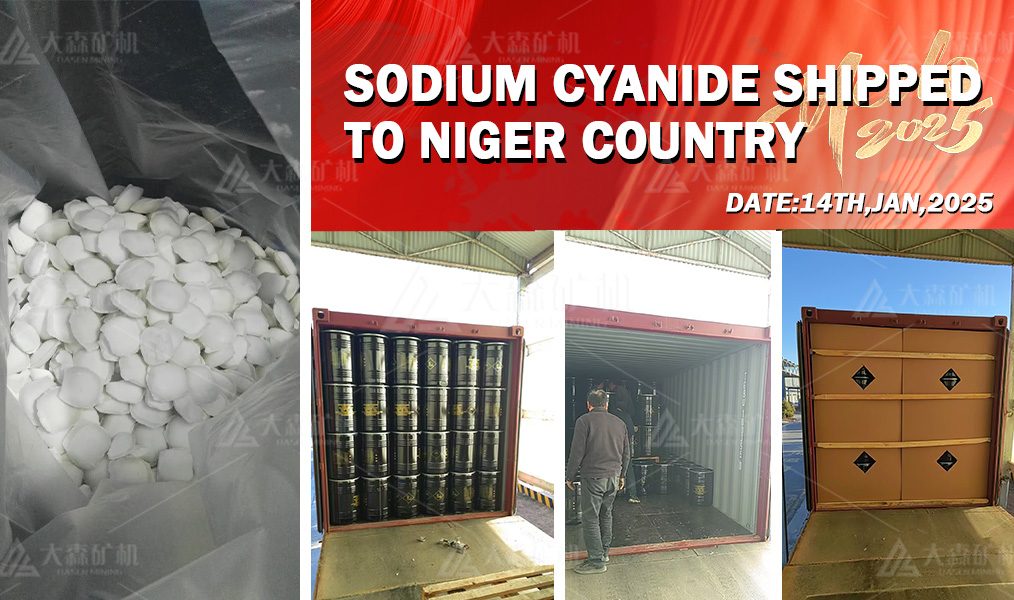

Last week, Dasen Mining shipped a batch of sodium cyanide to Niger. The shipment, packed in iron barrels, contains sodium cyanide with a purity of 98%. This is a trial order between both parties. If the customer confirms the quality, we will proceed with larger shipments in the future.

Our customer operates a gold cyanide plant, which is running smoothly and requires a steady supply of sodium cyanide as a leaching agent. Additionally, the customer will act as a distributor, supplying sodium cyanide to other gold mine owners in the region. We look forward to deepening our cooperation.

The gold mine uses a grinding and cyanide leaching process: gold ore is ground to a fine slurry (-200 mesh, over 90-95%), then cyanide leaching is performed. Activated carbon is used to directly adsorb dissolved gold from the slurry. The gold is then separated through carbon desorption and electrolysis, purified, and smelted. This full-mud cyanidation process is increasingly popular in gold processing plants due to its high efficiency.

The gold cyanide plant includes six main stages:

1. Raw material preparation

2. Stirring cyanidation leaching and activated carbon countercurrent adsorption

3. Gold-loaded carbon desorption and electrolysis

4. Gold mud separation, purification, and ingot casting

5. Activated carbon activation and regeneration

6. Cyanide-containing wastewater treatment

At Dasen Mining, our professional design institute determines the optimal leaching time and temperature through mineral processing tests. Our methods ensure high gold leaching efficiency, low equipment loss, and cost savings.

With rising gold prices, more gold mine projects are underway, especially cyanidation leaching plants known for high recovery rates. We have exported many leaching equipment sets, and our engineers are actively involved in building gold leaching plants worldwide. As these projects progress, sodium cyanide remains one of our best-selling products.

Whatsapp:+86 133 1927 7356

Email:[email protected]