Manganese ore processing methods:what are they?

Manganese is an essential mineral used in countless industrial applications, from steel production to electronics. However, extracting this crucial element from ore is no simple task. Let’s delve into the fascinating world of manganese ore processing and explore the challenges faced by miners worldwide.

There are two main types of manganese ores found naturally:

Manganese oxide ore

Manganese carbonate ore

Interestingly, about 57% of all manganese ore comes from manganese carbonate deposits. This higher percentage makes processing these ores particularly challenging.

The Challenges of Manganese Ore Processing

Manganese ores often present several difficulties during processing:

Many low-grade ores have fine particle sizes, making separation difficult.

Phosphorus-rich ores can contaminate the final product.

Iron impurities are common and need to be removed.

Some ores contain carbon monoxide, which requires special handling.

These challenges highlight why manganese ore processing remains an intricate and complex process in the mining industry.

Common Processing Methods

Despite the difficulties, miners have developed several effective methods to extract manganese from ores:

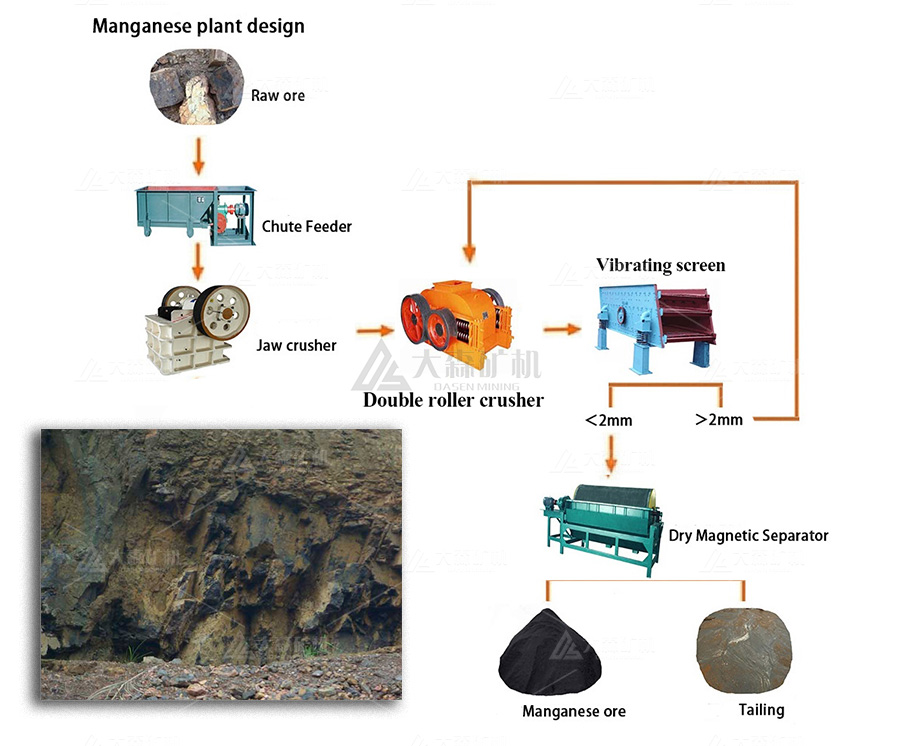

Reselection: This method is suitable for coarse-grained manganese oxide ores with simple structures. It involves crushing the ore to about 6-10mm and then sorting by gravity separation.

High-intensity magnetic separation: This technique has become increasingly important in recent years due to its ease of operation and versatility. It can increase the grade of manganese concentrate by about 24% – 25%.

Strong magnetic flotation: This combination of strong magnetic separation and flotation is highly adaptable and mainly suitable for manganese carbonate ores. It helps remove manganese slime and improve flotation grade.

Gravity magnetic separation: This method is typically used for manganese oxide ores. It combines strong magnetic separation with gravity separation to produce high-grade concentrates.

The Future of Manganese Ore Processing

As mining technology continues to evolve, we may see new methods emerge to tackle these challenges. However, understanding the complexities of manganese ore processing remains crucial for miners worldwide.

By mastering these techniques, miners can ensure a steady supply of this vital mineral for various industries. As demand for manganese continues to grow, innovative approaches to processing will likely play a key role in meeting this demand sustainably.

Manganese ore processing may seem complex, but understanding these intricacies is crucial for miners worldwide. From the challenges posed by fine particles to the various methods used for separation, each step in the process contributes to our ability to extract this essential mineral from the earth. As we look to the future, continued innovation in manganese ore processing will likely play a significant role in meeting global demands for this versatile element.

Whatsapp:+86 133 1927 7356

Email:[email protected]