In Myanmar, is Tungsten-Tin Ore Suitable for Beneficiation?

Xi’an Dasen Mining was commissioned by a tungsten tin mining company in Myanmar to test the beneficiation process and conduct research on samples of tungsten tin ore from July to August 2019.

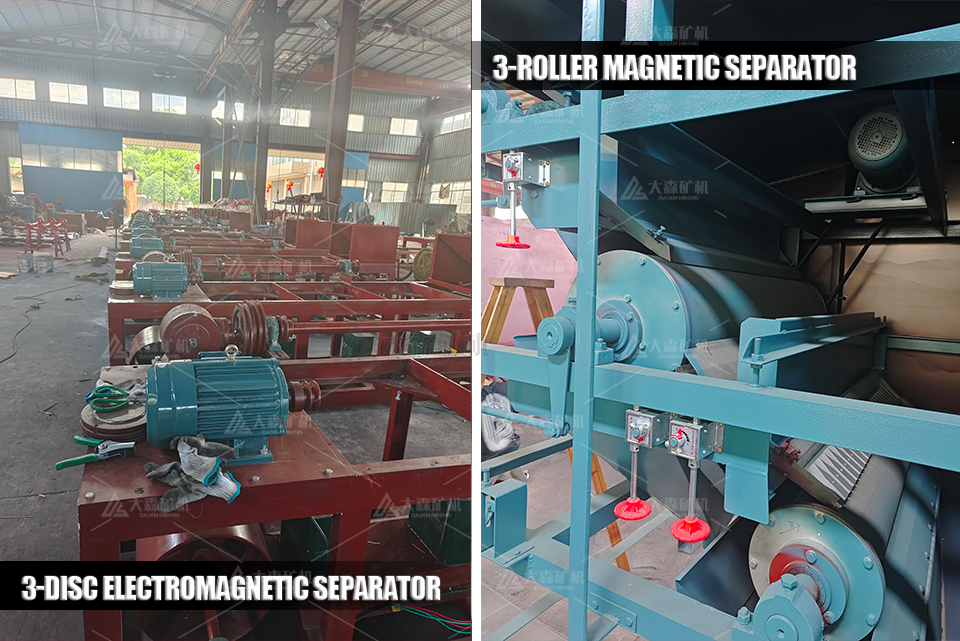

A detailed experimental study will be conducted on the mineral dressing process flow according to the symbiotic relationship and embedding characteristics of the tungsten-tin minerals and harmful components in the ore, The objective of this project is to provide technical and economic parameters for the “quality improvement and impurity reduction” and comprehensive recovery of the tungsten-tin ore dressing, to design and debug the plant, and to improve the economic benefits of the mine.

The raw ore contains Sn 0.82%, WO3 0.32%, Ag 46.50g/t, Pb 0.45%, S 1.41%, and As 2.22%. Analyzing the original mineral phase, the Sn share in the sizite phase is 93.54%; the WO3 share in the dark tungsten and white tungsten phases is 91.42%.

A study of the ore properties indicates that the mine contains complex gas thermal quartzite cassiterite, wolframite, and metal sulfide ores. Minerals recovered from the ore include cassiterite and wolframite (scheelite is not present in rock ore samples), metal sulfides are mainly arsenopyrite and pyrite, and quartz is the gangue mineral.

The whole process comprehensive condition flotation closed-circuit test is carried out based on the entire process open-circuit optimization test. Because the middling return of a small amount of reagent in the flotation closed-circuit test shall be adjusted appropriately, the dosage of reagent for sulfur removal and arsenic flotation shall be adjusted accordingly.

We can provide you with more information about the tin ore beneficiation plant. If you have any questions, please contact: Whatsapp:+86 133 1927 7356

Email:[email protected]