Maximizing Tin Recovery: How to Optimize Your Tin Processing Plant?

Recently, an African customer approached us with a common challenge: they have open-pit tin mines with high tin content in their area but are unsure how to efficiently establish a tin processing plant. Today, Dasen Mining will provide a concise overview of the tin ore processing methods to help address this concern.

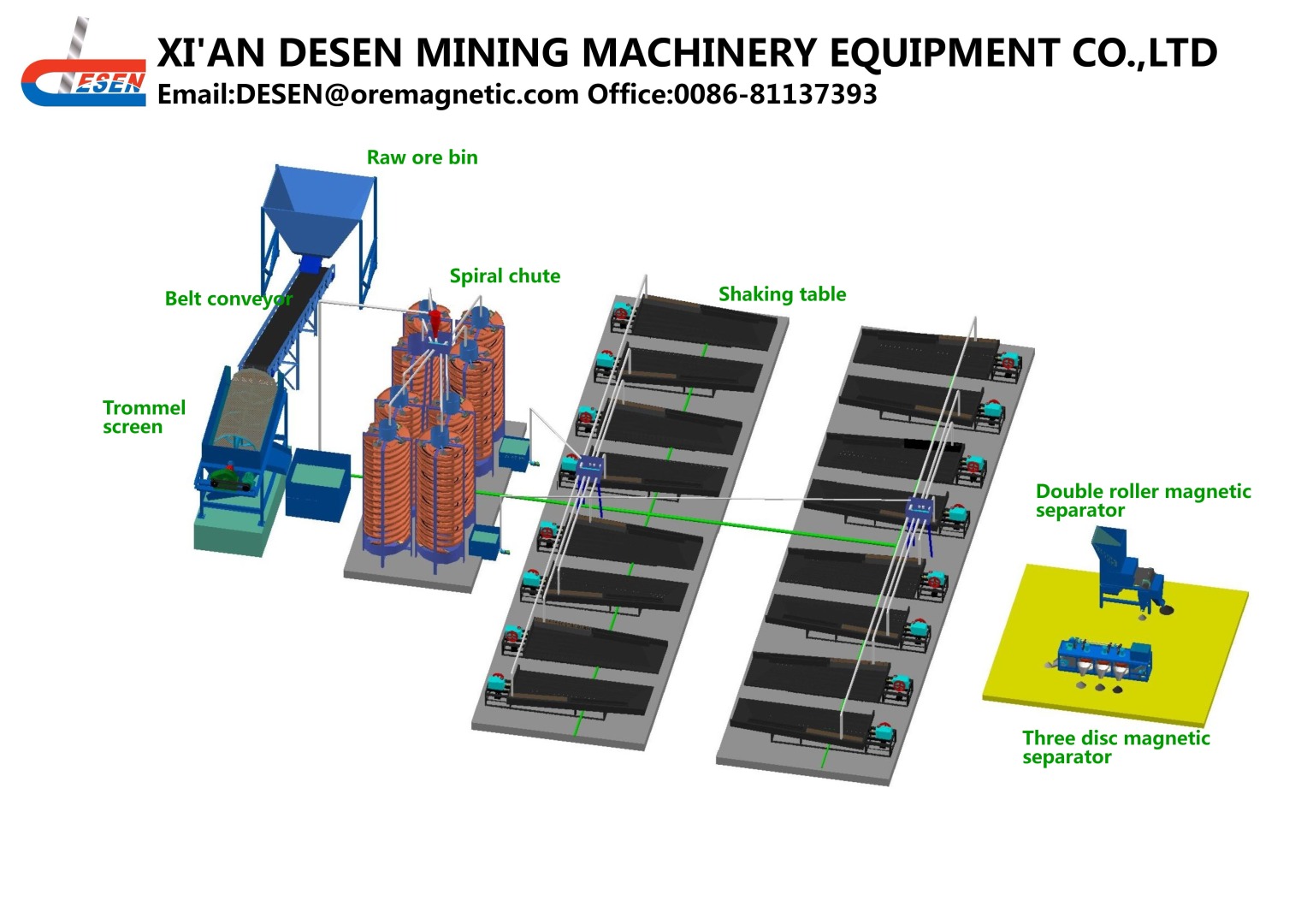

Open-pit cassiterite ore, commonly known as placer tin mines, is characterized by its high tin content. The density of tin minerals is significantly higher than that of ordinary minerals, making gravity separation an ideal method for beneficiation.

Traditional Gravity Separation Methods

Tin ore has traditionally been processed using gravity separation techniques, especially for placer tin deposits. The typical process involves:

1.Screening: Initial separation based on particle size.

2.Jigging: A jig machine is used for preliminary enrichment due to the density difference between tin and other minerals.

3.Dehydration: Removing excess water from the concentrated ore.

For placer tin ore with a low monomer dissociation degree, a more complex gravity separation process is often required:

1.Screening: Initial separation.

2.Jigging: Preliminary enrichment.

3.Rod Mill: Grinding to liberate finer particles.

4.Jigging: Secondary enrichment.

5.Dehydration: Final water removal.

This method leverages the significant specific gravity difference between tin and waste rock in sand tin ore, achieving a high beneficiation efficiency. It is an energy-saving, environmentally friendly, and cost-effective solution, making it an ideal choice for tin processing plants.

Emerging Technologies: Flotation and Magnetic Separation

As the particle size of cassiterite in the selected ore has decreased over time, the cassiterite flotation process has emerged as a viable option. This process is particularly effective for fine-grained tin ore, enhancing the overall recovery rate.

Additionally, tin minerals often contain various iron oxide minerals such as magnetite, hematite, and limonite. These minerals cannot be effectively separated from cassiterite through flotation and gravity separation alone. As a result, magnetic separation has become an integral part of the tin ore beneficiation process in recent years. This technique effectively isolates iron oxide minerals, ensuring a higher purity of the final tin concentrate.

If you have ideas or questions about tin process plant and industrial processing equipment, please contact us:

Whatsapp:+86 133 1927 7356

Email:[email protected]