What Are the Most Efficient Mining Methods for Lead and Zinc Ore?

The lead and zinc mining industry deals with ore of lead and zinc, which is a relatively difficult one to handle. In general, lead-zinc ore in the context of lead and zinc mining is leaner and the associated components are more complex than rich ore. Therefore, in the beneficiation industry within lead and zinc mining operations, it is crucial to separate lead-zinc ore efficiently.

As a result of an analysis of mining history and current technology in lead and zinc mining, the mining extraction method has improved. Heavy, durable and compact mining equipment improves cost-effectiveness and mining efficiency. Knowledge of zinc mining and processing is essential in lead and zinc mining: Zinc is used in many aspects of our lives, such as coatings and compounds. Zinc is an important material whether used in domestic or industrial environments. The following topics will more specifically describe the use, mining methods and beneficiation process of ore of lead and zinc in lead and zinc mining operations!

What is the use of zinc?

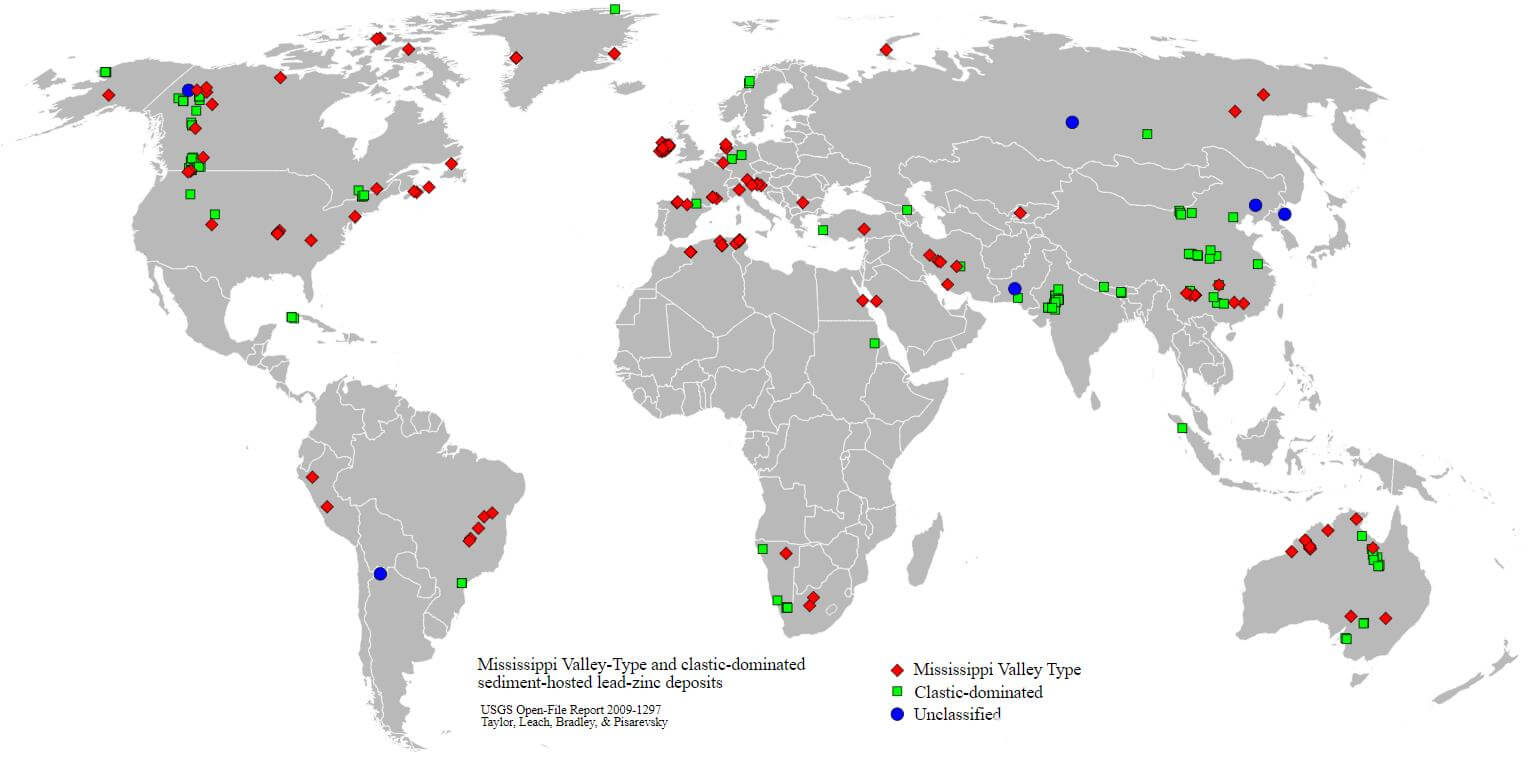

Anti-corrosion coating for steel, brass and other metals; Construction materials; Die – casting precision components; Making brass; Cosmetics and medicines; Micronutrients for humans, plants and animals; Semiconductor characteristics. Where is zinc mining carried out? The Red Dog Mine in Alaska is the world’s largest zinc mine, but zinc mines can be found in 50 countries around the world. Among the more than 50 countries, the world’s largest zinc producers in lead and zinc mining are Canada, Australia, China, Peru and the United States. Some zinc mines located in Canada, Australia, Ireland and Namibia will be closed due to exhaustion in the past ten years. Sedimentary rocks, volcanic rocks, intrusive rocks, crushed ore, or Mississippi valleys are the most common types of zinc deposits in lead and zinc mining areas.

Where is zinc mining?

The Red Dog Mine in Alaska is the world’s largest zinc mine, but zinc mines can be found in 50 countries around the world. Among the more than 50 countries, the world’s largest zinc producers are Canada, Australia, China, Peru and the United States. Some zinc mines located in Canada, Australia, Ireland and Namibia will be closed due to exhaustion in the past ten years. Sedimentary rocks, volcanic rocks, intrusive rocks, crushed ore, or Mississippi valleys are the most common types of zinc deposits.

Zinc mining process: More than 80% of zinc is extracted from underground mines in lead and zinc mining operations. 8% of zinc is mined in open pits, while the remaining 12% is mined by these two methods. Once removed from the soil, the concentrate is baked at a temperature of 950 degrees Celsius, which oxidizes zinc, sulfur and iron. The zinc and iron oxides will be reduced to powder form and filtered with dilute sulfuric acid, followed by neutralization and removal of contaminants by filtering. Zinc will be transformed into its final form in the foundry.

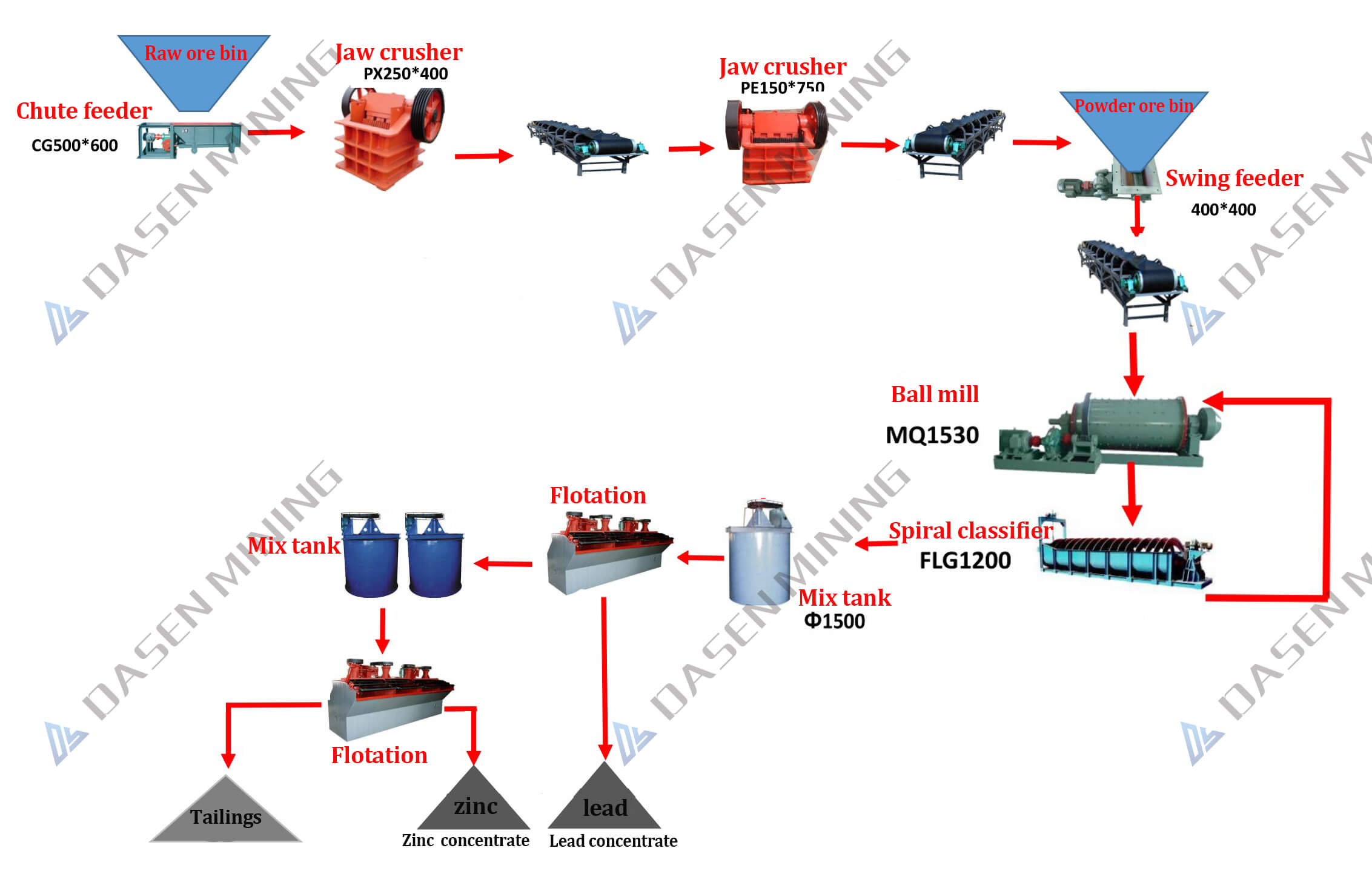

Lead – zinc ore beneficiation process: The characteristics of lead – zinc mineral resources in lead and zinc mining determine that the lead – zinc beneficiation process is mainly flotation. The flotation process of lead – zinc ore is divided into priority flotation process flow, mixed flotation process flow, etc. flotation process flow, asynchronous flotation Process flow, branched stream flotation process flow, flash flotation process flow and fast flotation process flow and other types.

Different processing methods should be developed for different types of lead – zinc ore in lead and zinc mining. Therefore, the process flow can reflect the process characteristics of the ore being processed.

According to the changes in properties of the ore and the adoption of new processes to improve the technical and economic indicators, the process of lead – zinc ore dressing should be improved over time. Flotation consists of two aspects: the flotation principle process and the internal structure of the flotation process in lead and zinc mining operations.

Whatsapp:+86 133 1927 7356

Email:[email protected]