Description

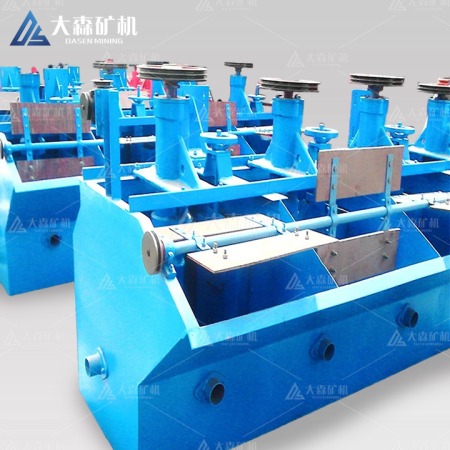

Name: flotation machine, mechanical flotation cell

Uses: beneficiation, mineral selection

Model: XJK,A,XJ

Feed particle size: 1-2mm

Processing capacity: 4-200T/H

Single tank volume: 0.35-2.43 tons / tank

Power: 1.5-11kw

Applicable Materials:

The XJK (Type A) series mechanical flotation cell is suitable for processing a wide range of minerals, including non-ferrous metals (copper, lead, molybdenum, gold), ferrous metals, and non-metallic ores.

Machine Structure and Operation:

This traditional self-priming flotation machine consists of a pulp tank, agitator, aeration system, discharge mineralization bubble device, and electric motor. It is designed to reduce ore grade and recover high-grade concentrates, particularly for fine-grained ores.

The XJK series excels in handling large air volumes and high throughput while maintaining a simple, low-maintenance design.

Working Principle of the XJK-Type Mechanical Flotation Cell

The XJK-type mechanical flotation cell consists of two primary components: a suction tank and an intermediate chamber. The suction tank, which can be either self-flowing or straight-through, draws in the pulp (mineral slurry) through a feeding pipe. Positioned between the tanks, the intermediate chamber houses the impeller, which is mounted on the lower end of the main shaft. A motor-driven pulley is located at the shaft’s upper end.

Air is drawn into the cell through an intake pipe. The pulp level in each flotation cell is regulated by a gate mechanism. Above the impeller, an air cylinder (vertical pipe) and cover plate are situated. The air cylinder incorporates adjustable holes for introducing the pulp feed, returning middling ore, or recirculating the slurry. These adjustments are made using a pull rod.

| Model | Volume(m3) | Impeller

Diameter(mm) |

Capacity(m3/min) | Impeller rotating speed(r/min) | Transmission

motor |

Scraper motor | Power(kg) | Inside dimension(mm) | Weight(kg) | |

| model | Power(kg) | model | ||||||||

| XJK-0.13 | 0.13 | 200 | 0.05-0.16 | 593 | Y90L-4 | 1.5 | Y80M2-4 | 0.75 | 504*520*700 | 266 |

| XJK-0.23 | 0.23 | 250 | 0.12-0.28 | 504 | Y100L-4 | 3.0 | Y80M2-4 | 0.75 | 604*620*820 | 389 |

| XJK-0.35 | 0.35 | 300 | 0.15-0.5 | 500 | Y90L-4 | 1.5 | Y80M2-4 | 0.75 | 700*700*906 | 430 |

| XJK-0.62 | 0.62 | 350 | 0.3-0.9 | 400 | Y132S-6 | 3.0 | Y90L-6 | 1.1 | 820*900*1156 | 630 |

| XJK-1.1 | 1.1 | 500 | 0.6-1.6 | 330 | Y132M2-6 | 5.5 | Y90L-6 | 1.1 | 110*1100*1269 | 1300 |

| XJK-2.8 | 2.8 | 600 | 1.5-3.5 | 280 | Y160L-6 | 11 | Y100L-6 | 1.5 | 1750*1600*1450 | 2325 |

| XJK-5.8 | 5.8 | 750 | 3.0-7.0 | 240 | Y200L-6 | 22 | Y100L-6 | 1.5 | 2200*2200*1200 | 3533 |

Advantages:

- Superior Separation Efficiency: Delivers exceptionally high separation accuracy, resulting in significantly lower clean coal ash content and increased yield, particularly for challenging coal separation processes. Compared to traditional mechanical stirring flotation machines, this technology can reduce clean coal ash content by up to 2%.

- High Throughput and Low Operating Costs: Offers a high processing capacity while maintaining low operational costs.

- Minimal Maintenance: The flotation cell’s simple design, devoid of moving parts, ensures easy maintenance and repair, reducing downtime and maintenance costs.

Features:

- Efficient operation: Low power consumption coupled with high suction capacity.

- Self-contained flotation circuit: Each tank independently functions as a suction, slurry suction, and flotation unit, eliminating the need for auxiliary equipment.

- Flexible design: Horizontal configuration allows for easy process adjustments.

- Precise control: Automatic pulp surface control enables effortless adjustments.

- Optimized pulp circulation: Minimizes coarse sand sedimentation through effective upper and lower impeller blade circulation.

Configuration:

The XJ-1, XJ-2, and XJ-4Y models utilize four or six basic slots. XJ-1 and XJ-2 models incorporate two-slot motor bodies, while XJK-3A, 4A, 5A, and 6A models feature two, four, or six tanks as basic units. The XJK-11 model combines one, two, or four basic tanks to create a series of flotation machines capable of coarse, fine, and sweep operations.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]