Description

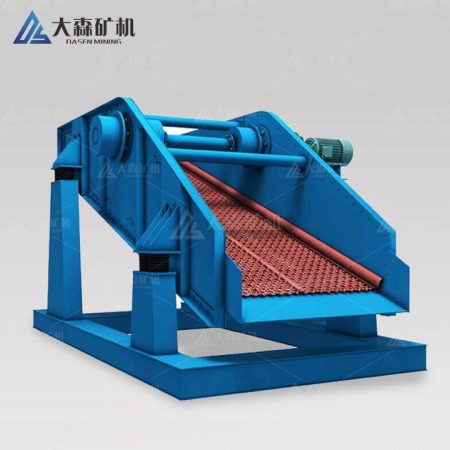

Name: SZZ series self-centering vibrating screen

Feeding particle size: 40-150mm

Motor power: 2.2-18.5KW

Production capacity: 20-300t/h

Application: In the screening of materials such as ores and coal, self-centering vibrating screens are used for coarse, medium-fine, and ultra-fine screening. Additionally, it can be used to de-cement and de-mediate materials.

Introduction:

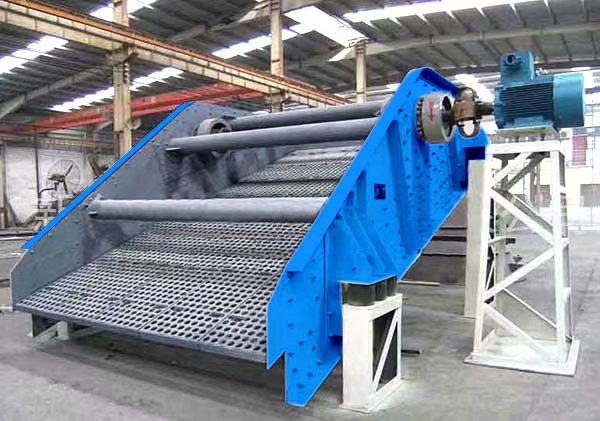

Self-centering vibrating screens are versatile machines employed for the coarse, medium, and fine screening of materials such as ores and coal across various industries. These screens also excel in de-cementing and de-mediating processes. The core components of a self-centering vibrating screen include a screen box, exciter, suspension (or support) system, and motor.

Widely utilized in mining, coal, smelting, construction, refractory, light industry, and chemical sectors, self-centering vibrating screens are indispensable for product classification, particularly in crushing operations. Renowned for their circular motion, simple structure, reliable performance, easy maintenance, and high efficiency, these screens are industry standards.

Available in hanging and seated configurations, self-centering vibrating screens can be single or double-layered. Transmission modes include left and right installation. Screen media options encompass woven mesh and perforated plate.

Beyond material separation, these screens find applications in diverse fields. The exciter’s main shaft, driven by a motor through a V-belt, induces vibration in the screen box via centrifugal force generated by unbalanced components. Adjusting the eccentric weight of the exciter modulates the vibration amplitude.

Advantages:

A key advantage of self-centering vibrating screens is the offset alignment of the pulley and bearing centerlines, which eliminates vibration, reduces belt wear, enhances screen amplitude, and boosts overall productivity. Additional benefits include:

- Powerful excitation through block eccentricity

- Low power consumption, noise, and extended service life

- Automatic discharge and enclosed design

- High screening accuracy with adjustable particle size and large capacity

- Simple, stable screen structure and easy maintenance

Working Principle:

Driven by an electric motor, the eccentric shaft, integrated with the screen box, rotates via a pulley system. This rotational motion generates centrifugal force, causing the screen box to execute a circular vibrational path. The unique eccentric design of the large pulley maintains a constant center distance between the pulleys throughout operation.

| Model | Specification | Max Feeding Granularity | Capacity | Motor Model | Motor Power | Weight |

| SZZ918 | 900*1800 | 40 | 20-25 | Y100L1-4 | 2.2 | 420 |

| SZZ₂918 | 900*1800 | 40 | 40-50 | Y100L1-4 | 2.2 | 570 |

| SZZ1225 | 1250*2500 | 100 | 70-100 | Y132S-4 | 5.5 | 1020 |

| SZZ₂1225 | 1250*2500 | 100 | 70-100 | Y132S-4 | 5.5 | 1320 |

| SZZ1530 | 1500*3000 | 100 | 90-200 | Y132M-4 | 7.5 | 1650 |

| SZZ₂1530 | 1500*3000 | 100 | 90-200 | Y132M-4 | 7.5 | 2870 |

| SZZ₂1540 | 1500*4000 | 100 | 90-200 | Y160L-4 | 15 | 4240 |

| SZZ1836 | 1800*3600 | 150 | 100-300 | Y180M-4 | 18.5 | 4500 |

| SZZ₂1836 | 1800*3600 | 150 | 100-300 | Y180M-4 | 18.5 | 5616 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]