Description

Beneficiation Centrifuge: A New Frontier in Fine Mineral Recovery

The beneficiation centrifuge is a cutting-edge gravity separation equipment that leverages centrifugal force. It is specifically designed to recover valuable minerals from fine-grained slurries. Unlike traditional gravity separation equipment, which often struggles to effectively separate minerals from muddy materials, beneficiation centrifuges offer a superior solution. As a relatively new technology, beneficiation centrifuges have garnered significant attention due to their high efficiency and precision. This article delves into the principles, advantages, and applications of beneficiation centrifuges.

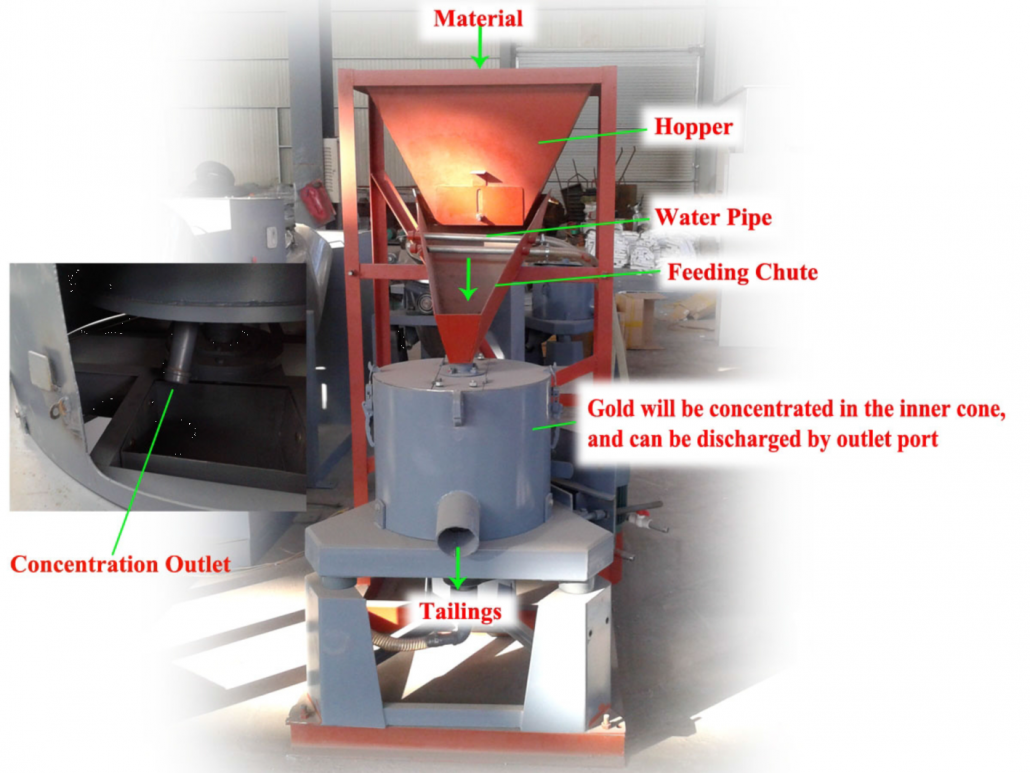

STLB Centrifugal Sand Separator

A revolutionary new gravity separation equipment, the STLB Centrifugal Sand Separator is specifically designed for the fine-grained ore beneficiation of precious metals like gold, silver, tin, and more. It’s particularly effective in recovering placer gold and rock gold, offering a mercury-free alternative for gold processing.

Key Benefits:

- Exceptional Recovery Rate: Achieves a monomer separation gold recovery rate exceeding 99%.

- Rapid Processing: Rock gold discharge cycle is as short as 1-4 hours, while placer gold can be processed in 4-8 hours.

- High Enrichment Ratio: Boasts an enrichment ratio of up to 500-1000 times.

- Versatile Application: Ideal for dry land gold, river gold, and rock gold processing.

Highly efficient and eco-friendly, our product delivers exceptional concentrating ratio and recovery rates while ensuring stable and reliable operation. Engineered with zero chemical and mercury content, it minimizes environmental impact. Designed for low water and electricity consumption, it offers reduced operational costs and easy maintenance. Its compact footprint further optimizes space utilization.

During the operation of a beneficiation centrifuge, the high-speed rotation of the rotor generates a substantial centrifugal force. This force is harnessed to enhance the gravity separation process of slip films, significantly improving the recovery of fine-grained minerals. By overcoming the challenges associated with low beneficiation efficiency for fine particles, this method is particularly well-suited for processing 0.075-grain sludge.

Beneficiation Centrifuge Process

A beneficiation centrifuge operates by subjecting ore slurry to high-speed rotation within a drum. The centrifugal force generated drives the slurry towards the drum’s inner wall, where it’s introduced through two feed points.

Heavier mineral particles are deposited on the drum’s inner surface and rotate with it at high speed. Conversely, lighter minerals rotate at a slightly slower speed, gradually moving towards the discharge end along the drum’s sloping inner wall in a spiral pattern. Tailings are subsequently expelled through a discharge separator.

The centrifuge employs a three-minute separation cycle. After this duration, the ore feed is halted, allowing for concentrate discharge. The discharge separator then automatically returns to its original position to capture the concentrate. High-pressure water is subsequently injected to flush the remaining concentrate from the drum wall before the cycle restarts with ore feeding and separation.

|

Model |

Capacity

(t/h) |

Fluidization

Water (m³/h) |

Slurry

Water (m³/h) |

Feeding

Density (%) |

Feeding

Size (mm) |

Concentrate

Weight (kg) |

Power

(kw) |

Weight

(t) |

Dimension

(mm) |

| STLB20 | 0-0.6 | 2-3 | 1.5-4 | 0-50 | 0-3 | 2 | 0.75 | 0.145 | 790*185*790 |

| STLB30 | 2-3 | 3-5 | 5-7 | 0-50 | 0-3 | 10-20 | 2.2 | 0.40 | 1180*1140*1250 |

| STLB60 | 8-12 | 7-10 | 8-12 | 0-50 | 0-3 | 30-40 | 4 | 1.00 | 1970*1670*1750 |

| STLB80 | 35-45 | 30-36 | 35-50 | 0-50 | 0-3 | 60-70 | 11 | 1.50 | 2300*1800*2200 |

| STLB100 | 70-80 | 55-80 | 70-120 | 0-50 | 0-3 | 80-90 | 22 | 2.00 | 2400*2000*2300 |

We can provide you with more information about the Centrifugal sand separator and gold processing plant . If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]