Why is Sample Testing Important for Lead-Zinc Flotation Optimization?

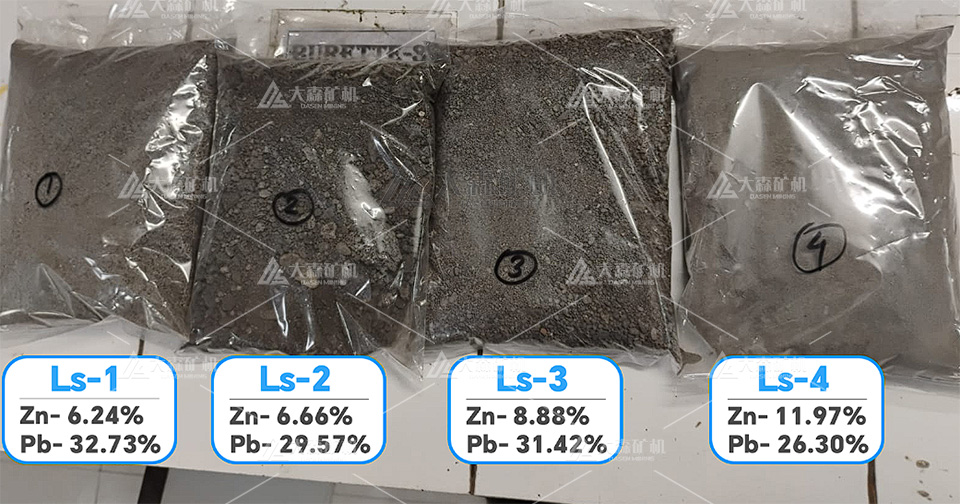

This week, we have a client from India. They possess zinc lead tailing with the following characteristics: the average lead content is 30%, zinc is 8.43%, and the size is below 3mm.

When it comes to the extraction of lead and zinc from such tailings, we employ the flotation method to obtain higher – grade concentrates.

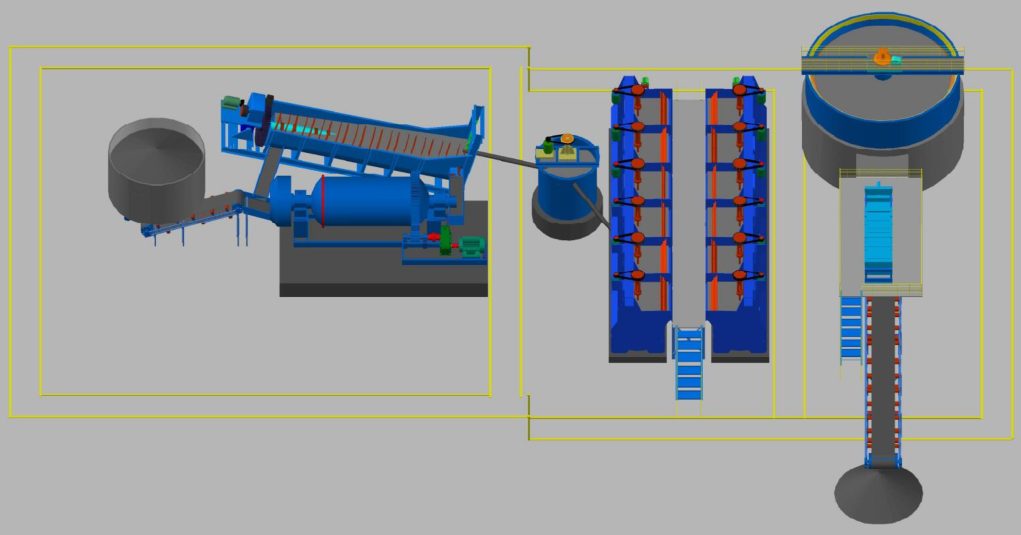

The entire process is as follows:

Step 1: Crushing the material to a size below 20mm. This initial step is crucial as it reduces the large – sized ore into smaller fragments, making it more manageable for subsequent operations.

Step 2: Grinding the material to a size where 80% is below 200mesh. Grinding is an essential part of the process, especially when considering the extraction of lead and zinc. In the case of zinc, grinding zinc – bearing minerals to the appropriate fineness is key to ensuring efficient separation. It exposes more of the valuable minerals for better interaction with the flotation chemicals.

Step 3: Add chemicals in the mixing tank to float the zinc and obtain the zinc concentrate. The carefully selected chemicals interact with the zinc – bearing minerals, causing them to attach to air bubbles and rise to the surface, forming the zinc concentrate.

Step 4: Add chemicals in the mixing tank to float the lead and achieve the lead concentrate. Similar to the zinc – floating process, specific chemicals are used to target the lead – bearing minerals, facilitating the lead extraction.

Chemical type and pulp pH play an extremely important role in the lead zinc ore flotation process. For the extraction of lead and zinc, these factors can significantly impact the efficiency of separation. So, we offer solutions to clients. We typically request people to send samples to us. In our factory, we have a dedicated lab to conduct the entire flotation experiment. This allows us to confirm all the conditions that affect the recovery rate. These conditions include not only the grinding size (which is crucial for both zinc and lead extraction, as improper grinding can lead to poor liberation of minerals), the pH value, but also the chemical types and dosages etc. Below is a glimpse of our lab, which serves as the heart of our efforts in optimizing the lead zinc flotation process for efficient lead extraction and zinc separation.

DASEN MINING is a group company that focuses on minerals like gold, copper, lead-zinc, chrome, tin, monazite, etc… our factory has 30+ yearsof history, and we have a complete supply chain of mineral separation processing, warmly welcome you to visit our factory.

Whatsapp:+86 133 1927 7356

Email:[email protected]