How Does the Open-Cut Mining Process Work?

Open-cut mining, also known as open-pit mining, is a method of extracting valuable minerals directly from the Earth’s surface. The large excavations created by this process are commonly referred to as open-pit mines. This method is widely used due to its efficiency and cost-effectiveness in accessing near-surface ore deposits.

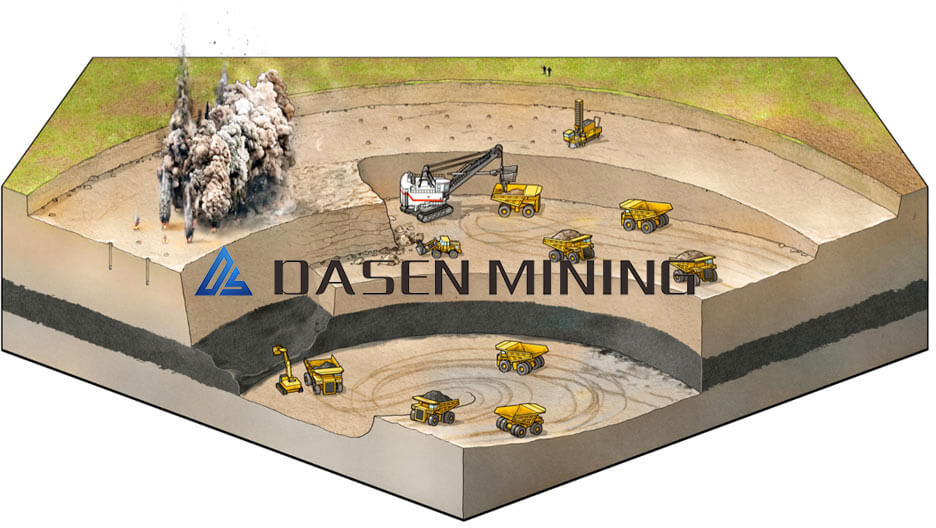

1. Classification of Open-Pit Mines

Open-pit mines can be classified based on their topographic features and the surface closed circle of the mine boundary:

Hillside Open-Pit Mining: This type of mining occurs above the surface closed circle and is suitable for deposits located on hillsides.

Depression Open-Pit Mining: This type occurs below the surface closed circle and is ideal for deposits in depressions or valleys.

2. Key Elements of Open-Pit Mining

Understanding the fundamental elements of open-pit mining is crucial for effective operations:

Bench: The ore and rock are divided into horizontal layers, or benches, with a specific thickness. Each layer forms a step-like pattern, with the height of each step known as the bench height.

Bench Slope: This is the inclined surface of the bench facing the goaf (the excavated area). The angle between the inclined plane and the horizontal plane is called the bench slope angle.

Step Platform (Flat): The horizontal space between the slope bottom line and the slope top line is known as the step platform. The width of this platform is critical for activities such as blasting, shovel loading, and transportation. Platforms used for these activities are called working platforms, while those used to intercept sliding rocks are known as safety (cleaning) platforms.

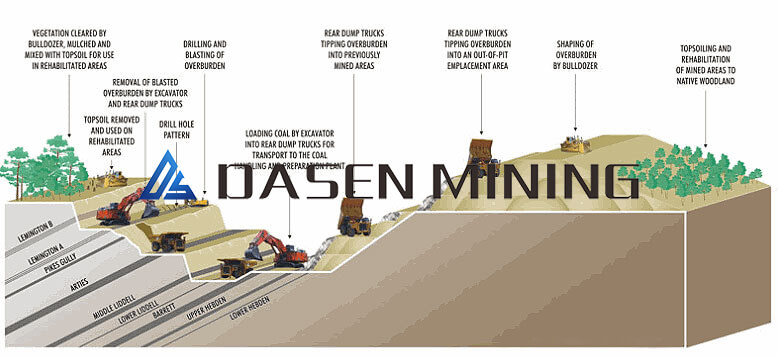

3. Open Cut Mining Process

The open-cut mining process involves several key steps:

1. Perforation: Drilling holes into the rock to prepare for blasting.

2. Blasting: Using explosives to break up the rock and ore.

3. Mining: Extracting the broken rock and ore from the pit.

4. Loading and Transportation: Loading the extracted material onto trucks or conveyors for transport out of the mine.

5. Rock Drainage: Managing water and other fluids in the mine to ensure safe and efficient operations.

The open cut mining process can be further categorized into:

Manual Mining: Relies on human labor for drilling, loading, and carting ore.

Hydraulic Mining: Utilizes high-pressure water jets to dislodge and transport mining materials, commonly used for soft sand deposits.

Mechanical Mining: Involves the use of heavy machinery and equipment to perform mining operations and transport materials through open-pit ditches or underground passageways.

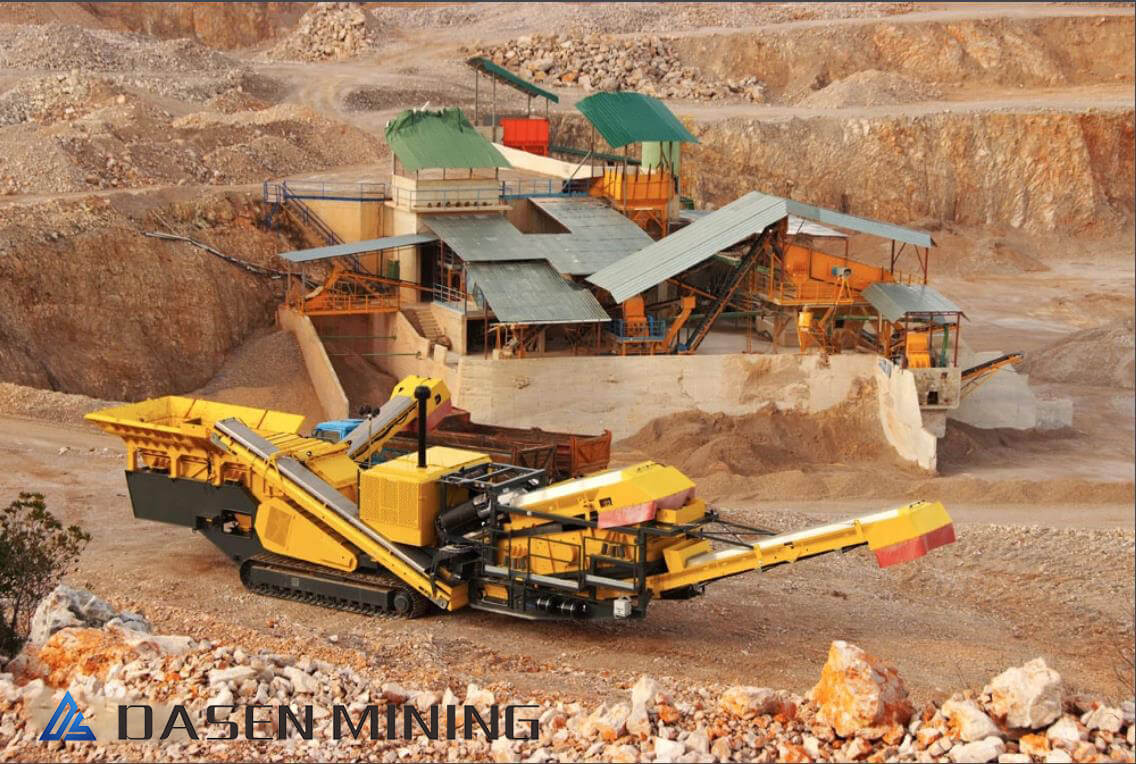

Equipment Needed for Open-Pit Gold Mines

Open-pit gold mining requires a variety of specialized equipment, including:

Excavators and shovels for digging and loading.

Haul trucks for transporting ore and waste rock.

Drilling rigs for creating blast holes.

Crushers and grinders for breaking down ore.

Conveyors for moving materials efficiently.

Separation and refining equipment to extract gold from other materials.

Open-cut mining is a complex but essential process for extracting valuable minerals. While it offers significant economic benefits, it also poses environmental challenges that must be carefully managed. As the Philippines lifts its ban on open-pit mining, the industry is poised for growth, but stakeholders must remain vigilant about the potential impacts and strive for sustainable practices.

If you have ideas or questions about gold process plant and equipment, please contact us: Whatsapp:+86 133 1927 7356

Email:[email protected]