Which Froth Flotation Cell Should You Choose?

Selecting the right froth flotation cell is crucial for optimizing mineral recovery and processing efficiency. The wrong choice can lead to poor recovery rates, excessive energy consumption, and increased maintenance costs. This guide will help you understand the different types of flotation machines available and make an informed decision based on your specific processing needs.

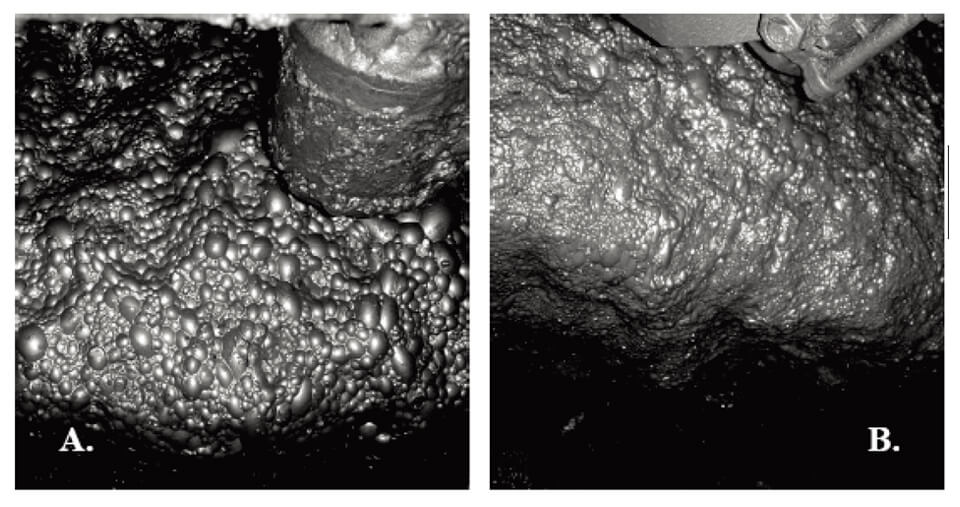

Before diving into equipment types, let’s briefly review what flotation cells do. These machines separate valuable minerals from waste rock by creating bubbles that selectively attach to target minerals. The mineral-laden bubbles rise to the surface as froth, which is then collected, while waste materials remain in the slurry.

Main Types of Flotation Cells

1. Mechanical Stirring Flotation Machine

How they work: These machines use a rotating impeller to both agitate the slurry and draw air into the mixture. They’re self-aerating, meaning they don’t require external air supply.

Key advantages:

Self-sufficient operation (draws its own air and slurry)

Simple installation with minimal auxiliary equipment

Easy operation and maintenance

Suitable for coarse particle flotation

Limitations:

Higher energy consumption due to dual function of impeller

Limited air volume control

Greater mechanical wear on components

Can over-grind fragile minerals

Best suited for:

Small to medium-scale operations

Applications requiring simple, robust equipment

Coarse particle flotation

Operations with limited technical expertise

2. Inflatable stirring flotation machine

How they work: These machines separate the aeration and stirring functions. An external blower supplies air while a low-speed impeller gently mixes the slurry.

Key advantages:

Precise air flow control via external blower

Lower energy consumption (30-50% less than mechanical types)

Gentler action preserves fragile minerals

Stable foam layer improves grade and recovery

Longer equipment life due to lower impeller speeds

Limitations:

Requires external blower system

More complex installation

Higher initial investment

Needs compressed air infrastructure

Best suited for:

Large-scale operations

Processing fragile or easily over-ground minerals

Applications requiring precise process control

Operations prioritizing energy efficiency

Available models include: CHF-X, XJC, BS-C, KYF, BS-K, LCH-X, and CLF series

How to Choose: Key Selection Criteria

1. Scale of Operation

Small scale (< 100 TPD): Mechanical stirring often more practical

Large scale (> 500 TPD): Inflatable stirring becomes more economical

2. Ore Characteristics

Hard, coarse ores: Mechanical stirring works well

Fragile, fine ores: Inflatable stirring prevents over-grinding

3. Energy Costs

High electricity costs favor inflatable stirring machines

Remote locations may prefer simpler mechanical types

4. Technical Capability

Limited technical staff: Choose mechanical stirring

Skilled operators available: Inflatable stirring offers better control

5. Capital vs. Operating Costs

Limited capital: Mechanical stirring has lower upfront cost

Focus on long-term efficiency: Inflatable stirring saves on operating costs

Making Your Decision

Consider these questions:

- What is your daily processing capacity?

- How fragile are your target minerals?

- What are your local energy costs?

- What level of process control do you need?

- What is your available capital budget?

While mechanical stirring flotation machines remain the most widely used due to their simplicity and lower initial cost, inflatable stirring machines offer superior performance for operations that can justify the higher capital investment. The energy savings and improved recovery rates often provide excellent return on investment for larger operations.

For personalized recommendations based on your specific ore characteristics and processing goals, our technical team can provide detailed analysis and testing services.

We can provide you with more information about the gold flotation plant. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]