What are the factors affecting rate of mineral leaching?

The cyanide leaching gold extraction method is a kind of gold ore beneficiation technology commonly used at home and abroad. The process is mature and the technical and economic indexes are ideal. In the process of mineral leaching, the main factors affecting the leaching rate of gold ore are the concentration of cyanide and oxygen, ore properties, gold particle size, pulp pH value, slurry content, pulp concentration, leaching temperature, and mineral leaching time.

01 Cyanide and oxygen concentrations

At present, cyanide leaching in gold mines often uses sodium cyanide as cyanide, and its consumption depends on the nature of the material and operating factors, often 20-200 times of the theoretical amount. During the cyanide leaching of gold ore, the cyanide content is generally 0.03%-0.08%. The dissolution rate of gold rises linearly to the peak with the increase of cyanide content, and then rises slowly; when the cyanide content reaches 0.15%, the gold dissolution rate has nothing to do with the cyanide content, and even decreases (due to cyanide hydrolysis).

In the process of gold cyanide leaching, oxygen or other agents (such as H2O2, CaO2, Na2O2, KMnO4, and Cl2) can be used as oxidants. However, at present, cyanidation plants generally choose to fill air. The dissolution rate of gold increases with the increase of oxygen concentration. The dissolution of gold is strengthened by oxygen-enriched solution or high-pressure gas cyanation.

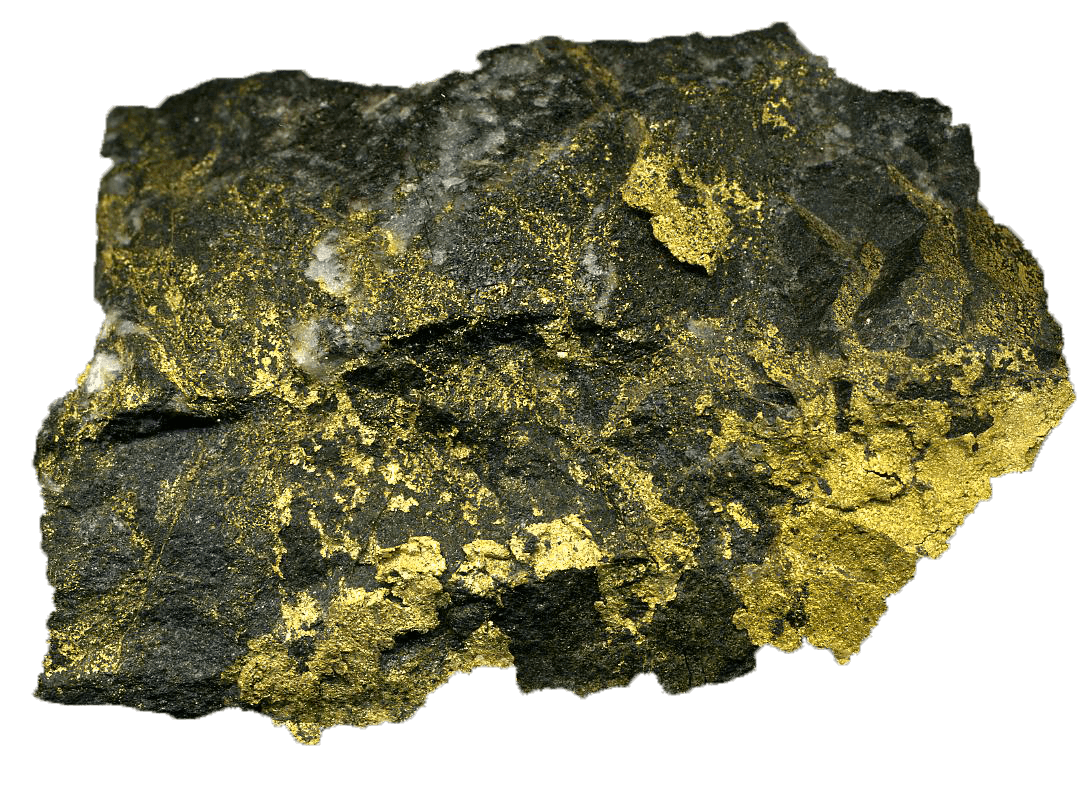

02 Ore properties

Some gold-bearing ores should not be directly treated by cyanide leaching. The high content of copper, arsenic, antimony, bismuth, and other components in the ore will greatly increase the cyanide consumption or consume the oxygen in the pulp and reduce the gold leaching rate. In addition, if the carbon content in the ore is high, the carbon will adsorb the dissolved gold and lose with the tailings. At this time, the influence of harmful impurities can be eliminated by pre-oxidation roasting or flotation.

03 Gold particle size

The size of gold particles mainly affects the cyanidation time, and the dissolution rate of coarse gold (> 74um) is slow. Therefore, gravity separation or flotation are often used to recover coarse gold in advance before cyanidation. In addition, it is also an important measure to improve the gold leaching rate to fully dissociate the fine gold particles in the grinding process.

04 pH value of pulp

In production practice, the pH value of pulp must be kept between 10.0-11.0. If the amount of alkali is too large, the pH value exceeds 12 or the amount of alkali is too small, and the pH value is less than 9, the cyanide leaching rate of gold ore will decrease.

Since the hydrolysis reaction of cyanide will volatilize toxic HCN, lime can be added to weaken the hydrolysis of cyanide and reduce the chemical loss of cyanide. Lime can also neutralize acids and precipitate harmful ions in pulp, so as to make the dissolution of gold in ideal conditions.

05 Slime content

During cyanidation, the content of slime and pulp directly affects the diffusion rate of components. When there are many slimes, the pulp content should be less than 22% – 25%, but the content should not be too low, otherwise, it will increase the consumption of cyanide.

06 Pulp concentration

The diffusion rate of cyanide and oxygen in the slurry will be directly affected by the slurry concentration. Too large concentration is not conducive to cyanide leaching. The reasonable slurry concentration should be determined through the beneficiation test.

For gold ore with less slime and impurities, high concentration leaching can be used, generally controlled at 40%-50%; for gold ore with complex mineral composition and more mud, low concentration leaching must be used, usually 25% about.

07 Leaching temperature

The cyanide leaching of gold will accelerate with the increase of temperature (caused by the increase of ion activity), but with the increase of temperature, the dissolved oxygen will decrease significantly, and the dissolved oxygen will be zero at 100 ° C, so the leaching cannot be carried out. At the same time, the self hydrolysis of cyanide increases, and the cyanide reaction of base metals accelerate, which increases the cyanide consumption and decreases the solubility of Ca (OH) 2, resulting in the low pH value of pulp. Generally, cyanide leaching does not need heating and can be maintained at 15-30 ° C.

08 Leaching time

Cyanidation leaching time depends on material properties, cyanidation methods, and cyanidation conditions. Generally, stirring cyanidation leaching is often more than 24h, sometimes more than 40H, gold cyanide telluride takes 72h, and percolation cyanidation leaching takes more than 5 days.

We can provide you with more information about the gold heap leaching plant. If you have any questions, please contact: Whatsapp:+8613319277356, Email:[email protected]