Which Leaching Methods Impact Gold Leaching with Cyanide as the Leaching Agent?

Cyanide leaching, a pivotal process in the extraction of precious metals, is an integral part of the gold leaching process. It utilizes a cyanide solution as a potent leaching agent to extract gold and silver from raw materials rich in these precious metals. This method is highly regarded for its effectiveness in liberating gold and silver from their ore matrices.

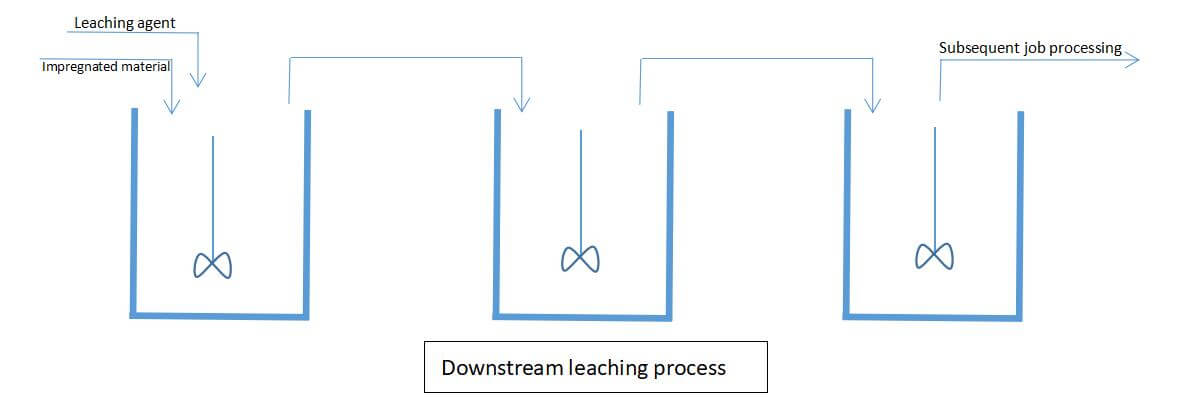

Downstream Leaching

In downstream leaching, the flow direction of the leached material and the leaching agent, in this case, the cyanide – based leaching agent, is the same. One of the main advantages of this approach within the gold leaching process is that it can yield a leaching solution with a relatively high content of target components. Moreover, the consumption of the leaching agent is low. However, it has its drawbacks. The leaching speed is notably slow, and the leaching time is extended, which is necessary to achieve a higher leaching rate. This extended time is crucial for the leaching agent to fully react with the gold – bearing materials and dissolve the gold effectively.

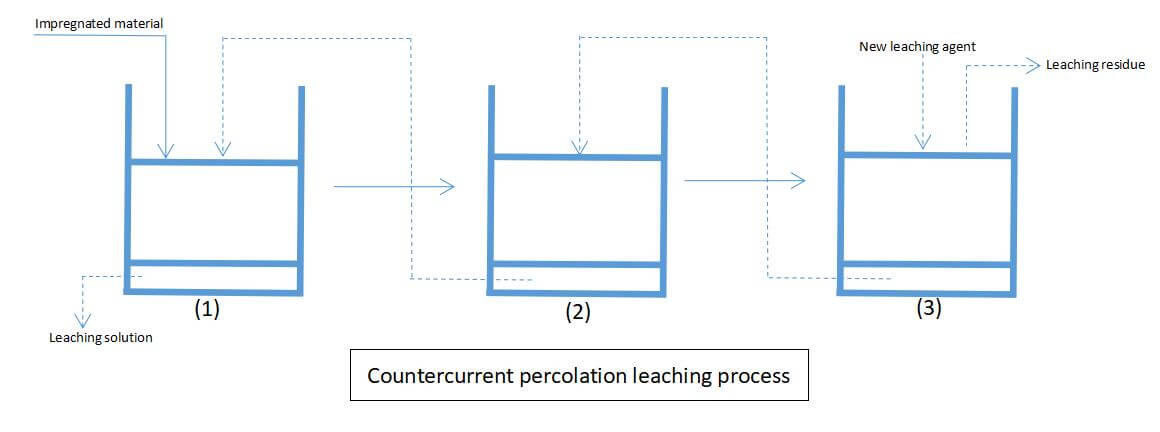

Countercurrent Leaching

Countercurrent leaching is distinct in that the movement direction of the leached material and the leaching agent is opposite. Here, the depleted material after several rounds of leaching comes into contact with the fresh leaching agent, while the original leached material interacts with the leaching solution. In the context of the gold leaching process, countercurrent leaching is efficient as it allows for the full utilization of the residual reagent in the leaching solution. Thus, the consumption of the leaching agent remains low. Nevertheless, its leaching speed is lower than that of cross – flow leaching. To obtain a high leaching rate, more leaching stages are required, which can increase the complexity and cost of the gold leaching process.

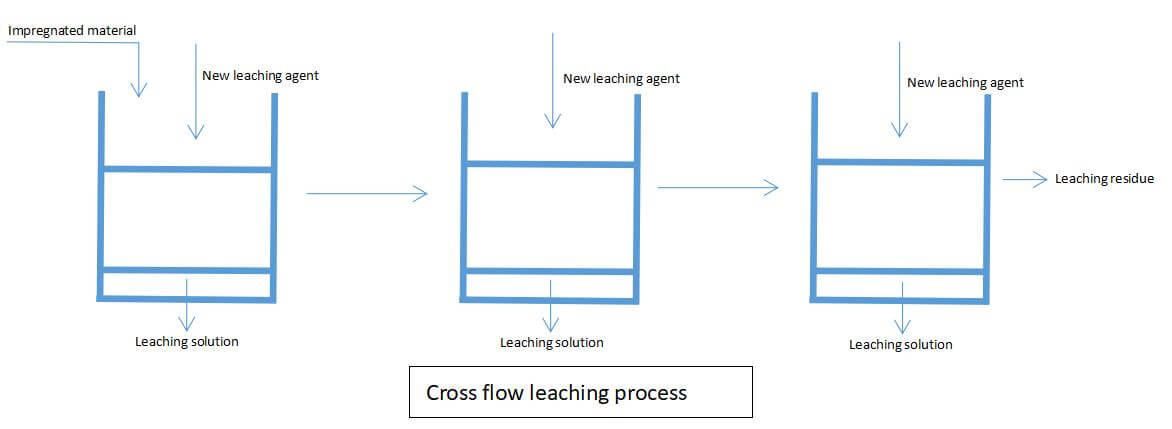

Crossflow Leaching

Crossflow leaching involves leaching the materials with several new batches of the leaching agent. Each time, the leaching solution obtained is evenly sent to subsequent operations for further treatment. In the gold leaching process, cross-flow leaching stands out for its faster leaching rate. The leaching time is short, and the leaching efficiency is relatively high. But it has some significant disadvantages. The volume of the leaching solution used is large, and the residual reagent concentration in the leaching solution is high, leading to substantial leaching agent consumption. Additionally, the content of target components in the leaching solution is low, which may require additional processing steps in the gold leaching process.

The leaching process of a percolation tank can be downstream, cross – flow, or countercurrent leaching. Heap leaching and in – situ leaching generally adopt the downstream circulating leaching process, mainly due to their large – scale operation and the need to simplify the process. Continuous stirring leaching typically uses the downstream leaching process. If cross – flow or countercurrent leaching is to be employed, solid – liquid separation operations must be added between all levels. Intermittent operation mixing leaching is usually downstream leaching, but cross – flow or countercurrent leaching processes can also be considered. However, solid – liquid separation is essential after each leaching, making the operation complex and less practical in production. Percolation leaching can directly yield a clear leaching solution, while the slurry from stirring leaching needs to undergo solid – liquid separation before it can be used for subsequent operation treatment in the gold leaching process. This separation step is crucial for ensuring the purity and effectiveness of the gold extraction process when using different leaching agents and methods.

Whatsapp:+86 133 1927 7356

Email:[email protected]