Reasons and solutions for low recovery rate cyanide leaching effect of gold ores?

There are many types of gold-bearing ores. Ores that cannot be leached smoothly under normal conditions (generally considered to have a leaching rate of less than 85%) and cannot be effectively recovered by gravity separation are difficult to leach (leach) ores. The reason why they are difficult to leach is because of the following reasons:

Reason: many associated minerals in the ore consume oxygen, alkali and cyanide, such as pyrrhotite and marcasite. During the cyanidation process, they are easily oxidized and decomposed to produce sulfuric acid, ferrous sulfate, basic ferric sulfate, ferric thiosulfate, etc. These substances react with cyanide or alkali so that a large amount of oxygen, cyanide and alkali are consumed before the dissolution of gold, which hinders the leaching of gold.

Solution: The pre-aeration alkaline leaching method has achieved good results for this type of ore. That is, before the ore pulp is cyanided and leached, it is aerated (oxygen) in an alkaline medium and stirred at the same time so that these minerals have enough oxidation and hydrolysis time to transform them into ferric hydroxide that is insoluble in cyanide. Then cyanide is added to the leach to effectively dissolve the gold.

Reason: The ore is accompanied by sulfide minerals such as arsenic and antimony. These minerals are oxidized in the cyanide solution, which not only consumes the reagent, but also the products are often thin films of insoluble compounds, such as arsenite, thioarsenite, antimonite, thioantimonite, etc., which cover the surface of gold particles and make gold difficult to dissolve.

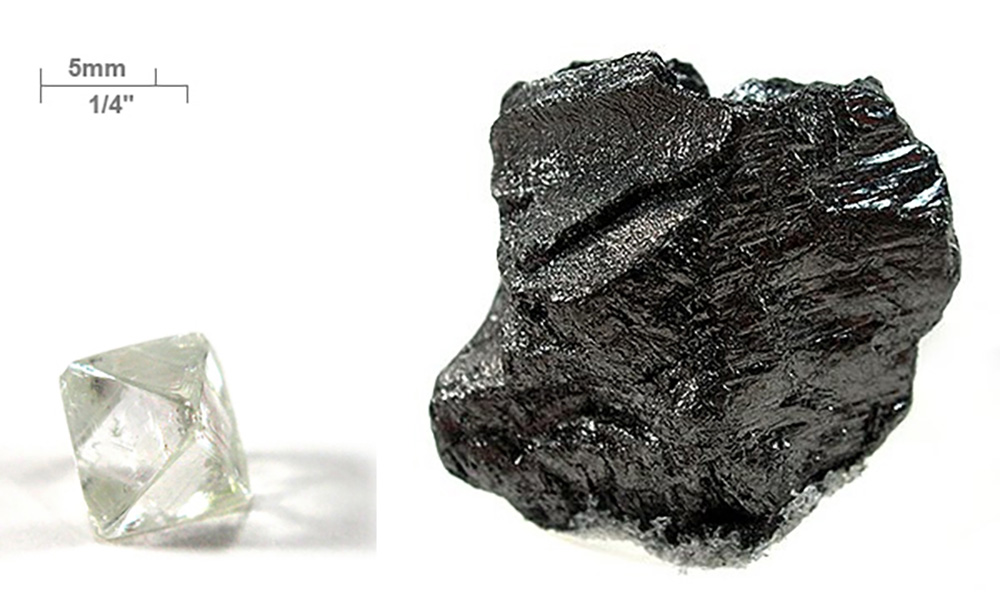

Reason: there is also a kind of gold ore containing carbon. Because there is active graphite or organic carbon in the ore, they will adsorb the dissolved gold and re-precipitate it, thus reducing the leaching rate of gold.

Solution: This type of ore can be pretreated in different ways depending on its carbon content. ① Physical method. Utilize the hydrophobicity of the surface of carbon minerals. When the carbon content is low, add a small amount of kerosene or coal tar before leaching to form a film on the carbon surface to inhibit the carbon from adsorbing gold. When the carbon content is high, add oil and separate it by flotation. ② Chemical method. Use roasting to oxidize carbon into CO and CO2 gas, or use sodium hypochlorite to oxidize it under stirring in an alkaline medium at 50~60℃, and then cyanide leaching.

Dasen Mining Machinery& Equipment Co.,ltd is a professional manufacturer of mineral separation equipment for gold, copper, lead-zinc, chrome, tin, tantalum, niobium and other non–metallic minerals including quartz, zircon, and barites, etc. After 30+ years of innovation and development, we can undertake from 10TPD-3000TPD separation plant, especially gold ore cyanide leaching plant and gold ore mobile trommel plant, gold/copper/lead-zinc/barite, etc flotation plant, chrome/tin/columbite/zircon sand, etc gravity&magnetic separation plant.

Conclusion

Addressing these challenges requires a tailored approach based on the specific characteristics of the gold ore. Understanding the underlying causes and implementing appropriate solutions can optimize cyanide leaching to achieve higher gold recoveries.

Whatsapp:+86 133 1927 7356

Email:[email protected]