Description

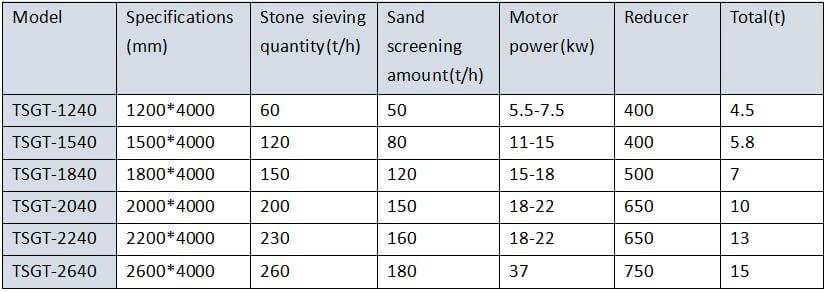

Name: Shaftless trommel screen

Feed particle size: ≤230mm

Production capacity: 10-400T/H

Motor power: 0.75-22kw

Screen size: 3-40mm

Screen material: wire mesh

Uses: classification of dry and wet materials, dragging mud, and dewatering of coarse particles

Composition: drum, frame, funnel, reducer, motor

Shaftless Drum Screen: Superior Screening Performance

Our shaftless drum screen offers significant advantages over traditional shafted drum screens, particularly in handling challenging materials. Designed for industries such as power generation, coking, construction, metallurgy, chemicals, and mining, this equipment excels in screening wet, sticky materials like coal, coal gangue, coke, and quicklime. By eliminating screen clogging often encountered in vibrating screens, our shaftless drum screen enhances screening efficiency and reliability.

Capable of processing materials ranging from coarse (100mm) to fine (less than 3mm), this versatile equipment has garnered widespread acclaim from our customers.

Shaftless Roller Screens: A Versatile Screening Solution

Shaftless roller screens operate at an optimal inclination of 5 to 20 degrees, depending on the material being processed. Driven by motors, diesel engines, or generators, these screens utilize a cylindrical design to effectively agitate and screen materials through forklift, excavator, or conveyor input. The absence of a shaft eliminates clogging issues and enhances durability.

Customization options include mobile configurations (tire or crawler) and protective covers for environmental protection. While primarily used in mining and construction, the versatility of shaftless roller screens extends to various industries. Compared to traditional screens, these offer increased output, accuracy, safety, and longevity. Key components include a motor, reducer, screen body, reinforcing rings, support wheels, frame, and hopper. The broad compatibility with diverse materials underscores the screen’s adaptability.

Advantages of the Vibrating Screen

- Reliable and Durable: The screen operates at low speeds, ensuring stable rotation, minimal maintenance, and extended equipment life. Its anti-clogging design enables efficient wet material processing.

- Optimized Screening Area: The large screening surface area maximizes contact with materials, prolonging the screen’s lifespan.

- Quiet and Clean Operation: The fully enclosed design minimizes noise and dust emissions.

- Enhanced Performance: The integration of a high-frequency, low-strength excitation mechanism effectively prevents blockages, accelerates screening, and boosts output.

- Anti-Blockage Features: Additional strike and anti-blockage mechanisms provide further protection against material accumulation.

- Self-Cleaning Capability: A screen cleaning function ensures efficient removal of residual material before shutdown.

Simplified Assembly and Disassembly

The Shaftless trommel screen modular design facilitates efficient storage and transportation to the construction site. The only component requiring disassembly is the finished stacking belt conveyor. This process involves loosening the bottom fastening bolts and suspension cables, followed by detaching the conveyor from the main frame.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact: Whatsapp:+86 133 1927 7356

Email:[email protected]