Description

Description:

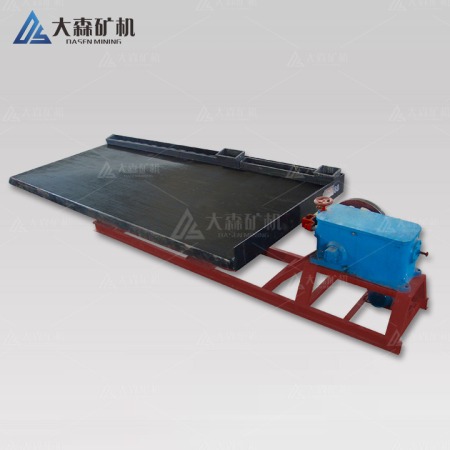

Our gravity spiral chute has been enhanced with a cutting-edge centrifugal concentrator, significantly boosting its efficiency. This advanced equipment excels at separating a wide range of minerals, including iron, tungsten, tantalum, niobium, gold, coal, monazite, rutile, and zircon. Suitable for particles ranging from 0.02 to 0.3 mm, the concentrator leverages specific gravity differences for optimal separation. Rigorous testing by industry experts, including researchers, designers, manufacturers, and mining professionals, has validated the concentrator’s exceptional performance, advanced sorting capabilities, and remarkable potential for widespread adoption.

Application:

Ideal for separating minerals with distinct specific gravity, our gravity spiral chute equipped with a centrifugal concentrator is designed for processing materials such as iron, tin, tungsten, tantalum, niobium, gold, coal, monazite, rutile, and zircon. This high-performance system effectively handles particle sizes between 0.02 and 0.3 mm.

Gravity Spiral Chute: Method and Principle

A gravity spiral chute is a mineral processing device that leverages centrifugal and gravitational forces to separate materials based on specific gravity and particle size.

Operational Process:

The gravity spiral chute is installed vertically using a sturdy iron or wooden frame. Sand is fed into the chute’s upper inlets by a sand pump, with water added to adjust the ore concentration. As the slurry flows downward in a swirling motion, centrifugal force is generated, causing particles of different densities to migrate radially within the chute. Heavier minerals tend to move towards the outer edge of the spiral, while lighter particles concentrate closer to the center.

The separated concentrate is collected in a bucket at the chute’s end, while tailings are discharged into a separate collection area.

Based on the particle size of the processed ore, gravity spiral chutes can be categorized into three main types:

- Coarse-grained spiral chutes: These chutes are designed for processing larger ore particles, with a maximum feed size exceeding 2-3mm and reaching up to 100-200mm.

- Placer spiral chutes: Specifically engineered to handle ore particles with a size of approximately 2-3mm, these chutes are commonly used in placer mining operations.

- Slime spiral chutes: Ideal for fine-grained ores, these chutes are designed to process particles smaller than 0.074mm.

Emphasizing efficiency and adaptability

The gravity spiral chute offers a compact and efficient solution for material handling. With its high recovery rates, precise separation capabilities, and robust construction, it ensures optimal performance. Its lightweight design, corrosion resistance, and low maintenance requirements contribute to reduced operational costs and extended service life. This versatile equipment can handle varying feed rates, densities, sizes, and grades, making it suitable for a wide range of applications.

| Model | Outside

Dia (mm) |

Pitch

(mm) |

Lateral slope

(°) |

Maximum starts

per unit |

Feeding size

(mm) |

Feeding density

(%) |

Capacity

(t/h) |

Dimension

(mm) |

Weight

(t) |

| 5LL-400 | 400 | 240,180 | 9 | 2 | 0.2-0.02 | 25-55 | 0.15-0.2 | 460*460*1500 | 0.05 |

| 5LL-600 | 600 | 450,360,270 | 9 | 3 | 0.2-0.02 | 25-55 | 0.8-1.2 | 700*700*1600 | 0.15 |

| 5LL-900 | 900 | 675,540,405 | 9 | 4-2 | 0.3-0.03 | 25-55 | 2-3 | 1060*1060*4000 | 0.40 |

| 5LL-1200 | 1200 | 900,720,540 | 9 | 4-2 | 0.3-0.03 | 25-55 | 4-6 | 1360*1360*5230 | 0.60 |

| 5LL-1500 | 1500 | 540,720 | 9 | 4-2 | 0.3-0.02 | 25-55 | 8-6 | 1560*1560*5230 | 0.80 |

We will have professional technicians to solve the problem for you.

You can send us a private letter if you don’t know anything about the gravity spiral chute:

Whatsapp:+86 133 1927 7356

Email:[email protected]