Description

Emphasizing the versatility and precision

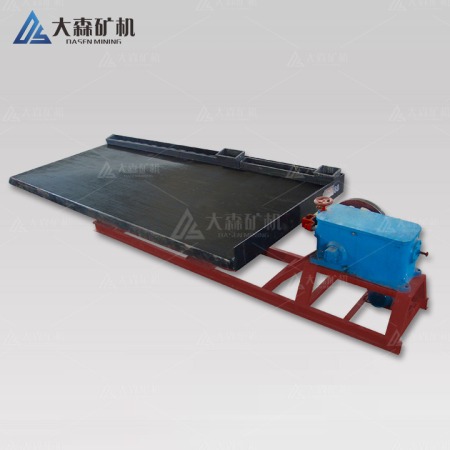

A high-precision 6s table shaker is designed to efficiently separate a wide range of minerals including non-ferrous, black, and precious metals like tungsten, tin, tantalum, iron, manganese, chromium, titanium, bismuth, lead, and gold. It can handle ore and sludge particle sizes from 2mm to 0.02mm, and pyrite from 4mm to 0.02mm. By adjusting the bed form, it can also be used for fine coal, slime, and other materials with sufficient specific gravity differences. Suitable for various operations such as roughing, concentration, and scavenging, this shaker can effectively separate different particle sizes including coarse sand (2-0.5mm), fine sand (0.5-0.074mm), and sludge (-0.074mm).

High-Performance Surface Material Offering exceptional strength and durability, our surface material boasts low water absorption, ensuring it won’t warp or deteriorate over time. Its resistance to wear and chemical corrosion makes it ideal for demanding applications. Additionally, it provides excellent adaptability and operational stability, even in challenging environments.

Shaker Selection Model for Mining Applications:

- High-capacity production-scale shakers (4.5m, 6s): Optimized for throughput and efficiency.

- Economical beneficiation shakers (3.1m): Balancing performance and cost for various ore types.

- Compact beneficiation shakers (2.1m): Suitable for limited space and flexible deployment.

- Laboratory-scale experimental shakers (1.1m): Designed for process development and testing.

Shaking tables are particularly well-suited for recovering fine gold from various minerals. They offer easy installation, operation, and low energy consumption, making them an environmentally friendly solution.

6S Fine Gold Recovery Shaker Table Installation Types

6S fine gold recovery shaker tables can be categorized into three primary types based on underframe construction.

1. Standard Shaker: This type lacks a channel steel underframe and requires a concrete pier, embedded steel plate, or channel steel for foundation stabilization. While suitable for experienced users familiar with shaker replacement, its installation complexity has led to declining popularity in recent years.

2.Small Channel Steel Shaker: Equipped with a 10# channel steel underframe, this shaker necessitates a concrete foundation with embedded screws for frame attachment. Alternatively, the channel steel frame can be integrated into the concrete pier for added stability.

3. Large Channel Steel Shaker: Featuring a robust 28# national standard channel steel underframe, this type offers superior stability and can be temporarily placed on a concrete floor. For long-term use, expansion bolts are required to secure it to a concrete floor with a minimum thickness of 15 cm. To prevent dirt accumulation and facilitate cleaning, a concrete pier raised at least 10 cm above ground level is recommended.

An overview of how to make the installation foundation for a 6S shaker can be found above. This should be helpful for friends.

Display of the gold selection effect for the shaker table plants:

We can provide you with more information about the gravity machine and gold processing plant.If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]