Description

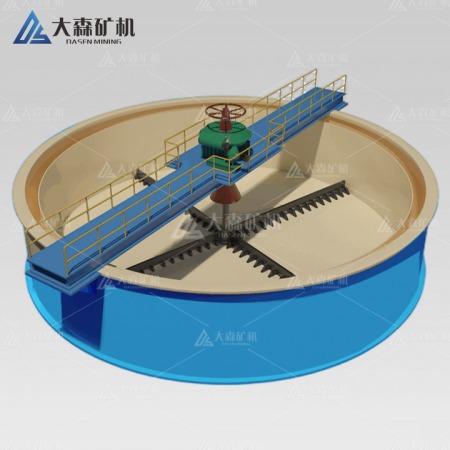

Product name: GX High-efficiency thickener, thickening equipment, gravity sludge thickener, thickener tank

Precipitation area:2.54-7846m²

Processing capacity: 5.6-30t/d

Product features: corrosion resistance, acid and alkali resistance, simple operation

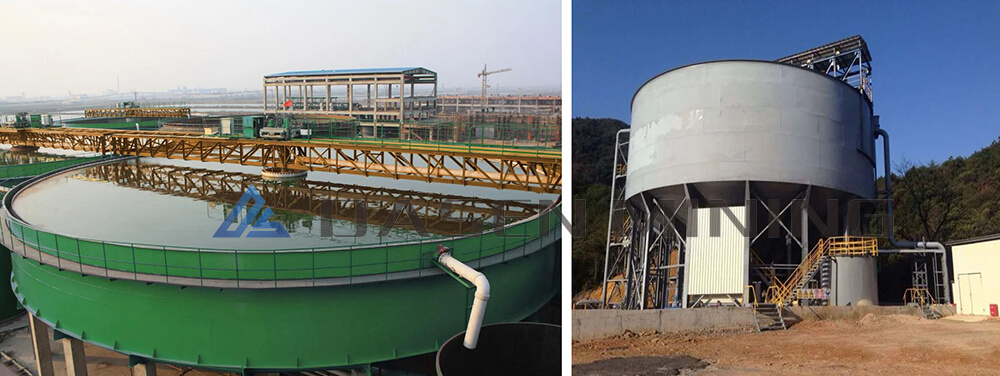

Product improvement: inner diameter up to 100m

Scope of application: This thickener is widely used in metallurgy, chemical industry, coal, non-metallic mineral processing, environmental protection and other industries.

Applications: Ideal for dewatering concentrates and tailings in mineral processing, this equipment significantly increases pulp density, typically from 20-30% to 40-70%, enhancing overall process efficiency.

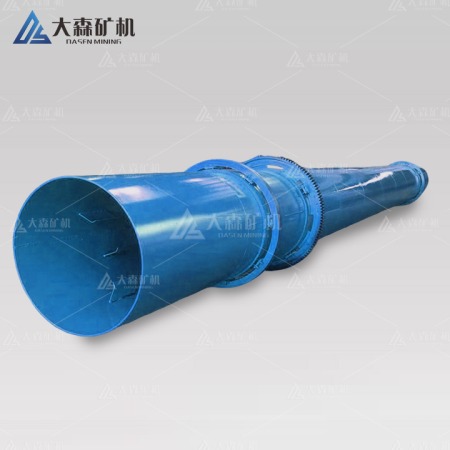

Structure: Tank body, degassing tank, feeding mixing drum, motor transmission device, rake frame lifting device, slow flow device, overflow weir, rake frame, feeding device, vertical shaft.

Features:

- Accelerated settling: Flocculant is added to increase particle size, promoting rapid sedimentation of solid particles.

- Optimized settling distance: Inclined plates reduce the settling distance of ore particles, enhancing efficiency.

- Enhanced thickening: The process combines flocculation, filtration, and compression to increase the processing capacity of the thickened mud layer.

- Automated operation: Equipped with automatic controls for streamlined operation.

Flocculation: Introducing a specific amount of flocculant to the ore pulp induces the formation of larger, heavier flocs. These flocs settle more rapidly, leading to increased concentration efficiency.

Working Principle:

Thickener equipment typically comprises a circular thickening tank and a rake scraper system. Raw water enters the tank through the upper portion of the central column and is distributed evenly by a diversion device towards the outer perimeter.

A rotating truss, driven by a motor, moves the rake arms in a circular motion around the tank’s center. The lower rake scrapers collect settled solids or sludge and push them towards the central sludge well for removal. Simultaneously, the upper rake scrapers collect floating solids or scum and move them to a scum discharge point.

Dasenmining offers high-rate thickeners with a fixed bridge design to handle substantial wastewater flow rates. This technology enables efficient treatment of up to 600 m³/hour of wastewater. These systems are primarily employed in aggregate washing facilities.

Thickening Equipment offers a range of advantages for efficient solid-liquid separation:

- High performance in a compact design: Achieve exceptional results with a smaller footprint.

- Customized solutions: Precisely tailored thickener type and size based on rigorous testing and process-specific guarantees.

- Optimized flocculant use: Minimize chemical consumption while maximizing thickening efficiency.

- Efficient feed system: Ensure consistent and optimal slurry introduction.

- Robust construction: Built for durability and long-term reliability.

- Flexible installation: Choose between ground-mounted or elevated support structures with welded or flanged connections.

- Extended lifespan: Reduce maintenance costs with minimal part replacement.

- Damage prevention: Hydraulic drives and rake lifts safeguard the thickener from wear and tear.

- Energy efficiency: Lower operating costs through reduced power consumption.

- User-friendly operation: Simple control and management system for ease of use.

| Model | Inner diameter of tank(mm) | Height of tank(mm) | Sediment area(m2) | Rotating speed of rake | Lifting height of rake(mm) | Driving motor model | Driving motor power(kW) | Lifting motor model | Lifting motor power(kW) | Weight of steel tank(kg) | Weight(kg) |

| GX-3.6 | 3600 | 1700 | 10.2 | 1.1 | 200 | Y100L-6 | 1.1 | PZ0.8AB | 0.8 | 2829 | 6650 |

| GX-5.18 | 5182 | 2134 | 21 | 0.8 | 300 | Y132M1-6 | 4 | PZ0.8AB | 0.8 | 5340 | 10460 |

| GX-7.5 | 7500 | 2800 | 44.1 | 0.427 | 300 | Y132M2-6 | 5.5 | Y132S-8 | 2.2 | 10258 | 17320 |

| GX-9 | 9000 | 2800 | 63.6 | 0.427 | 300 | Y132M2-6 | 5.5 | Y132S-8 | 2.2 | 15980 | 23680 |

| GX-12 | 12000 | 3600 | 110 | 0.35 | 300 | Y132M-4 | 7.5 | Y100L1-4 | 2.2 | 25589 | 42756 |

| GX-15 | 15000 | 4000 | 177 | 0.15 | 300 | YCT200-4B | 7.5 | Y112M-6 | 2.2 | 36050 | 59000 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]