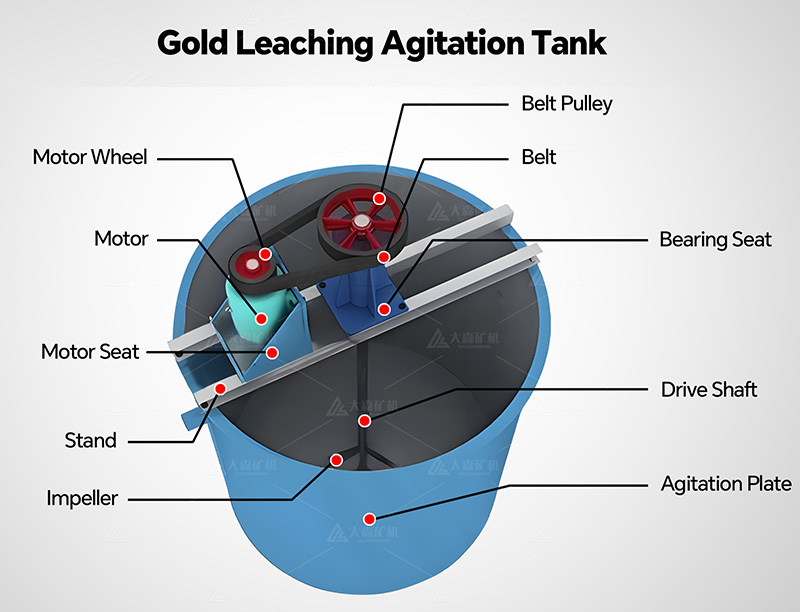

Description

A leaching agitation tank is a leaching equipment for cyanide leaching. In the gold cyaniding process, a leaching agitation tank is applied to leach and carbon-absorb ore pulps whose fineness is -200 meshes and whose density is less than 45%.

Gold Leaching Agitation Tank Advantage:

1. The impeller of this leaching tank is lined with wear-resistant rubber, low rotation speed, and long service life.

2. Moderate agitation intensity, and uniformly distributed in pulp concentration and fineness, which can improve the leaching rate of cyanidation and the adsorption rate of carbon;

3. Adopt two new impellers, the agitation tank features a large impeller diameter, low rotation speed, and small power consumption, which can reduce the wear of carbon;

4. The air enters the tank through the transmission hollow shaft, and the air disperses evenly with the blade agitation;

5. Smooth movement of ore flow, even pulp mixture, less power consumption;

6. The hollow shaft is ventilated to the bottom end, and the air enters the tank with uniform distribution and small bubbles;

Gold Leaching Tank Design

The gold leaching agitation tank is equipped with a carbon screen, carbon pump, and other equipment. The impeller is made of steel and wrapped with rubber. The upper and lower impellers are connected by bolts, which improves the leaching tank’s balance ability and service life.

The main shaft is divided into two layers and connected by flange pipes, which is more convenient for shipment. The air holes are numerous and dispersed to ensure smooth mixing of gas and liquid.

With dual impellers rotating and agitating, ore pulps move downward and then diffuse along with the damping plate. Air is fed in the tank from the lower end of the shaft and blended with ore pulps to form a uniform suspending mixed liquid.

Our Cases

Technical Parameters

| Model | Tank dimension

diameter ×height (mm) |

Effective

volume (m³) |

Impeller

speed (r.p.m) |

Impeller

Diameter (mm) |

Motor

power (kw) |

Tank

Weight (kg) |

Gross

weight (kg) |

| SJ2.0×2.5 | 2000×2500 | 6 | 52 | 909 | 2.2 | 1609 | 2144 |

| SJ2.5×3.15 | 2500×3150 | 13.14 | 935 | 2241.36 | 3095 | ||

| SJ3.0×3.0 | 3000×3000 | 18 | 40.85 | 1130 | 4 | 3391 | 4583 |

| SJ3×3.15 | 3000×3150 | 18.93 | 43 | 2801.12 | 4160.6 | ||

| SJ3×3.5 | 3000×3500 | 21 | 2974.69 | 4334.6 | |||

| SJ3.15×3.55 | 3150×3550 | 24 | 1260 | 3330.15 | 4322.8 | ||

| SJ3.5×3.5 | 3500×3500 | 30 | 52 | 1310 | 5.5 | 4285.6 | 5025 |

| SJ3.5×4 | 3500×4000 | 32.7 | 4630.6 | 5429 | |||

| SJ3.55×4.0 | 3550×4000 | 33.6 | 43 | 4 | 4059.6 | 5025 | |

| SJ3.7×4.2 | 3700×4200 | 38.4 | 42 | 5057.76 | 6153 | ||

| SJ4.0×4.5 | 4000×4500 | 48 | 35 | 1750 | 7.5 | 6105.17 | 7569 |

| SJ4.5×5.0 | 4500×5000 | 71.57 | 1750 | 7505.78 | 10864 | ||

| SJ5.0×5.6 | 5000×5600 | 98 | 31 | 2046 | 11 | 10482.4 | 14291 |

| SJ5.5×6.0 | 5500×6000 | 112 | 2100 | 14209 | 18745 | ||

| SJ7.0×7.5 | 7000×7500 | 245.4 | 21 | 2400 | 22 | 22090.22 | 29030 |

| SJ7.5×8.0 | 7500×8000 | 268.6 | 2900 | 18.5 | 24594.36 | 32796 | |

| SJ8.0×8.5 | 8000×8500 | 342 | 16.4 | 3200 | 30 | 33488.82 | 42467.3 |

| SJ8.5×9.0 | 8500×9000 | 395 | 18.5 | 3300 | 36695.5 | 4662 |

Gold Leaching Related Question:

1. How to prepare the raw material?

Proper ore preparation is crucial for efficient gold leaching. This involves crushing and grinding the ore to an appropriate particle size to expose the gold-bearing minerals. The particle size should be optimized to ensure maximum surface area and accessibility of gold for the leaching solution.

2. What chemicals should be used during the leaching?

Selection and optimization of leaching reagents are vital for efficient gold leaching. Cyanide is commonly used as a leaching agent for gold extraction. The concentration and composition of the leaching solution, such as cyanide concentration, pH, and the addition of other additives, should be carefully controlled and monitored to achieve optimal leaching conditions.

3. How long time does the ore pulp stay in leaching tanks?

Optimizing the residence time ensures sufficient contact between the leaching solution and the gold-bearing ore particles.

4. How to control the PH?

using alkaline or acidic reagents, pH control systems help maintain the desired pH level for efficient gold dissolution.

Whatsapp:+86 133 1927 7356

Email:[email protected]