Description

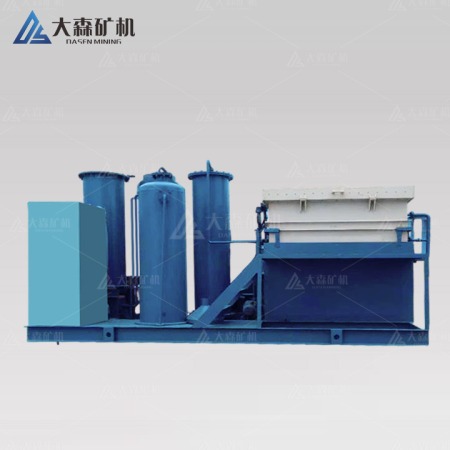

Product name: Desorption Electrolysis System, Desorption electrolysis equipment complex, Desorption and Electrowinning System

Handling capacity: ≥3.5kg/t

Application: used for cyanidation to extract gold from gold-loaded carbon to extract fixed gold

Structure: An output shaft of the motor is connected to the outer magnetic cylinder, thereby forming a sealed whole between the pump and motor. The inner magnetic cylinder has an impeller attached to one end, the outer magnetic cylinder and the motor run synchronously, under the action of centrifugal force, the medium can circulate.

High-Temperature, High-Pressure Gold Recovery System

This gold ore beneficiation system employs high-temperature and high-pressure desorption and electro-accumulation to extract gold mud from gold-loaded carbon. Subsequently, cyanidation is used to recover solid gold from the gold mud.

Process Overview:

- Desorption Electrolysis: The system utilizes the Y13-150/200/250 process model, operating at 150°C and 0.60 MPa. Sodium hydroxide serves as the desorption agent, and the process typically takes 8-16 hours.

- Desorption Efficiency: Under these high-temperature, high-pressure conditions, the desorption rate exceeds 98%.

Key Advantages:

- High efficiency gold recovery

- Low consumption of resources

- Rapid desorption electrolysis process (approximately 12 hours)

Standard Temperature and Pressure Cyanidation

Gold extraction from gold-loaded carbon is achieved through desorption and electrowinning processes conducted at standard temperature and pressure. This method employs specialized gold beneficiation equipment to remove gold mud from the carbon.

The desorption and electrolysis process operates under normal temperature and pressure conditions using CC13-150/200/250 equipment. The process temperature ranges from 90 to 95°C, while the desorbents sodium hydroxide and sodium cyanide are utilized for a duration of 48 to 72 hours.

Key disadvantages of this method compared to high-temperature, high-pressure processes include:

- Lower work efficiency

- Increased consumption of materials

- Extended processing time,

Working Principle:

The system employs a two-stage process: desorption and electrolysis.

- Desorption: Activated carbon, with its affinity for anions, is introduced into the system to replace the Au(CN)2- complex, thereby desorbing gold. This process occurs in a desorption tower.

- Electrolysis: The gold-laden solution from the desorption stage is transferred to an electrolytic cell. Here, ionization is utilized to recover solid gold. The crude gold produced undergoes further purification to yield finished gold.

In essence, the system involves desorbing gold from the carbon using a specific chemical environment and then recovering the gold through electrolysis.

| Desorption rate(%) | Electrolysis Rate(%) | Installed Capacity(kW) | Desorption Temperature(℃) | Electrolysis Volt(v) |

| >96 | >99 | 30 | 95 | 1.5-3(DC) |

| Electrolysis Current(A) | Capacity(kg/time) | Electrolysis liquid flow(t/h) | Weight(kg) | External dimension(mm) |

| 200 | 300 | 1.5 | 2430 | 4120*2100*4130 |

Key Features:

- Energy Efficiency: Simultaneous electrolysis and desorption processes eliminate the need for heat exchange, accelerating operation and reducing power consumption by up to 75% compared to traditional systems.

- Eco-Friendly Regeneration: Non-toxic desorption compounds, including a carbon activator, enable carbon regeneration without fire, saving costs and minimizing environmental impact.

- Safe and Cost-Effective: Free from sodium cyanide, the process is both budget-friendly and environmentally sound.

- Efficient Gold Recovery: Gold-bearing sludge can be extracted easily without the need for reverse electrolysis.

- Enhanced Safety: Triple safety measures, including an intelligent system, automatic pressure control, forced release mechanism, and safety valve, ensure a secure operation.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]