Description

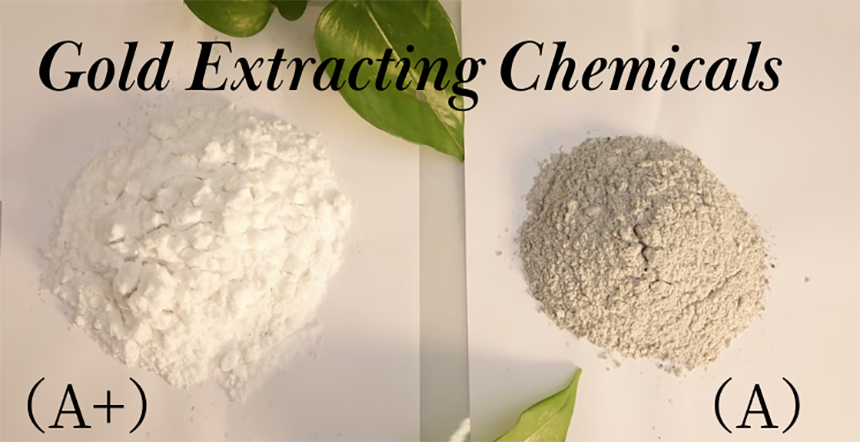

Environmental type gold extracting chemicals are a new high-tech product for use in gold leaching as the substitute for sodium cyanide.

It is mainly used in the leaching production of gold and silver oxide ore, primary ore and sulfide ore, with low toxicity and environmental protection performance, stable applicability, strong leaching rate, high recovery speed, etc.The product is powdery, easily soluble in water, and can be used after being dissolved.

Environmental Type Gold Extracting Chemicals Advantage:

High leaching rate: Our company’s products can effectively leach gold and silver from ores with a high leaching rate.

Short leaching time: Compared with sodium cyanide, the leaching cycle is shorter (leaching time can be shortened by 15-30%).

Anti-interference ability: In addition to being environmentally friendly, our gold extraction chemistry incorporates effective stabilizers. These stabilizers significantly reduce the adverse impact of harmful substances like arsenic, sulfur, and carbon on the leaching process.

Ease of use: Moreover, our products demonstrate exceptional solubility in water. Consequently, the application method closely resembles that of sodium cyanide, resulting in convenient preparation and use.

Gold Leaching Agent And Cyanide-free Application:

- Applicable ore types: golden and silver oxidized ore, primary ore, high-sulfur and high-arsenic gold ore, cyanidation slag, gold concentrate, pyrite cinder, and anode mud, etc;

- Applicable beneficiation process:

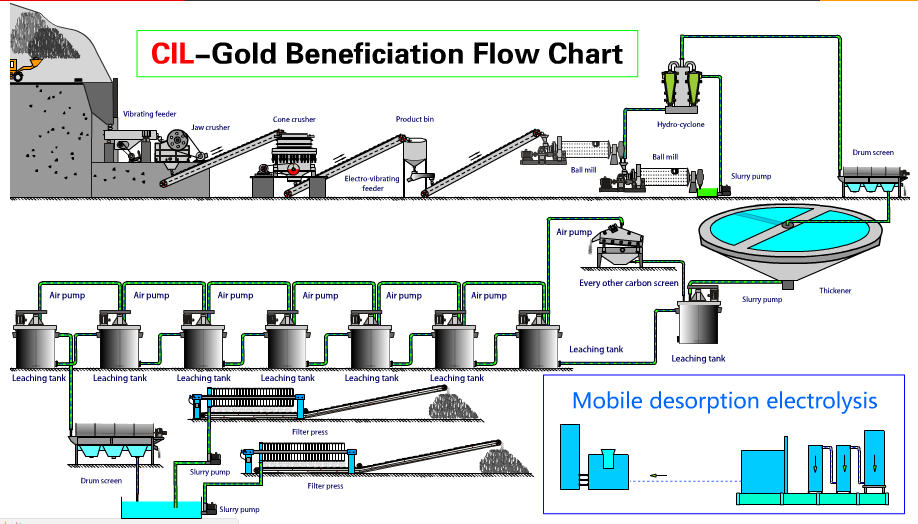

Gold CIL/CIP leaching:

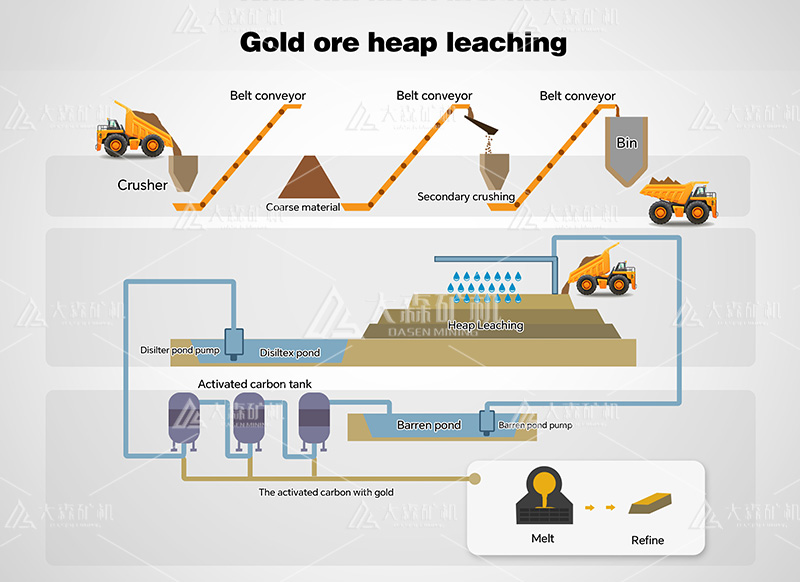

Heap leaching:

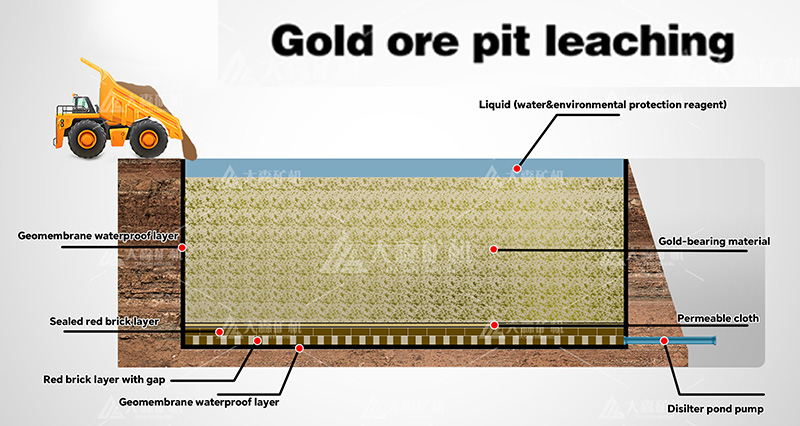

Vat/Pond leaching

Technical Parameter

| Components Number: | CAS Number | Approximate(%)by Wt. |

| Sodium carbonate(Na2CO3) | 497-19-8 | 5-15 |

| Sodium chloride(NaCL) | 7647-14-5 | 15-30 |

| Ammonium Chloride (NH4CL) | 12125-02-9 | 10-15 |

| Glycine (C2H5NO2) | 56-40-6 | 20-35 |

| Sodium lodide (Nal) | 7681-82-5 | 30-45 |

| Urea (CO(NH2)2) | 57-13-6 | 10-25 |

| Iron carbide(Fe3C) | 12011-67-5 | 0.01-0.05 |

Test Result in Using NaCN, CLC(common leaching chemical),Eco-LC(ours Environmental type gold extracting chemicals)

| Ore Sample Name | Category | Leaching Rate of Au(%) |

Final Dosage(kg/) | Carbon Absorption Rate(%) | Leaching Cost Comparison $/ton | ||||||||||||

| NaCN | CLC | Eco-LC | Eco-LC -NaCN |

NaCN | CLC | Eco-LC | Eco-LC -NaCN |

NaCN | CLC | Eco-LC | Eco-LC -NaCN |

NaCN | CLC | Eco-LC | Eco-LC -NaCN |

||

| Gold in Mail | Oxidized gold | 91.54 | 91.48 | 91.52 | -0.02 | 3.6 | 4 | 3.9 | 0.03 | 96.42 | 95.89 | 96.40 | -0.02 | 10.24 | 10.22 | 9.10 | -1.14 |

| Egypt gold mine | Oxidized gold | 92.46 | 92.15 | 92.43 | -0.03 | 1.1 | 1.5 | 1.1 | 0 | 97.80 | 97.10 | 97.75 | -0.05 | 3.46 | 3.42 | 3.40 | -0.06 |

| Tanzania goldmine | Oxidized gold | 93.56 | 93.14 | 93.55 | -0.01 | 1 | 1.2 | 1.05 | 0.05 | 96.22 | 95.99 | 96.15 | -0.07 | 4.45 | 4.20 | 3.95 | -0.5 |

| BF T1 goldmine | Oxidized gold | 97.97 | 97.24 | 97.98 | 0.01 | 4 | 4.2 | 4.2 | 0.02 | 98.24 | 98.10 | 98.20 | -0.04 | 10.18 | 10.08 | 8.99 | -1.19 |

| BI gold mine | Oxidized gold | 94.64 | 93.98 | 94.61 | -0.03 | 2.2 | 2.8 | 2.65 | 0.45 | 97.56 | 97.12 | 97.55 | -0.01 | 6.48 | 6.44 | 6.40 | -0.08 |

| NE N1 gold mine | Oxidized gold | 95.49 | 95.12 | 95.52 | 0.03 | 2.2 | 2.4 | 2.1 | -0.1 | 96.64 | 96.60 | 96.65 | 0.01 | 2.80 | 1.45 | 1.14 | -1.66 |

| NI gold mine | Oxidized gold | 98.75 | 98.15 | 98.80 | 0.05 | 4 | 4.3 | 3.85 | -0.15 | 97.28 | 97.26 | 97.29 | 0.01 | 2.96 | 1.96 | 1.80 | -1.16 |

| Gold in Sudan | Mixed | 92.86 | 92.16 | 92.66 | -0.20 | 1.1 | 1.5 | 1.2 | 0.1 | 96.84 | 96.42 | 96.80 | -0.04 | 6.12 | 5.96 | 5.55 | -0.57 |

Instructions for use

1. Dissolution Method: Golden Cicada can be fully dissolved in water under normal temperature. Generally, dissolution is accelerated in flowing water or through vigorous stirring. To enhance this process, a dosing pool can be constructed adjacent to the barren solution pool in heap leaching operations. This allows backwater, which has passed through carbon, to directly wash Golden Cicada and dissolve it into the barren solution pool.

2. Dosage

The dosage is about 2/10000-10/10000 of the ore (200-1000 grams of drug/ton of ore). The nature, taste, and pH of the ore affect the dosage. The specific dosage needs to be determined based on the ore dressing experiment.

3. Usage steps

Step 1: When using, first adjust the aqueous solution and slurry solution to alkaline, and adjust the pH value of the solution to 10-11.

Step 2: During the entire leaching process, the slurry pH value must always be maintained at 10-11.

Step 3: Add gold extracting agent, and keep the concentration of gold extracting agent in the slurry or aqueous solution between 5/10000-10/10000 during the entire leaching process.

Our Gold-extracting Chemicals Case

Whatsapp:+86 133 1927 7356

Email:[email protected]