Description

Name: Deoxygenation tower

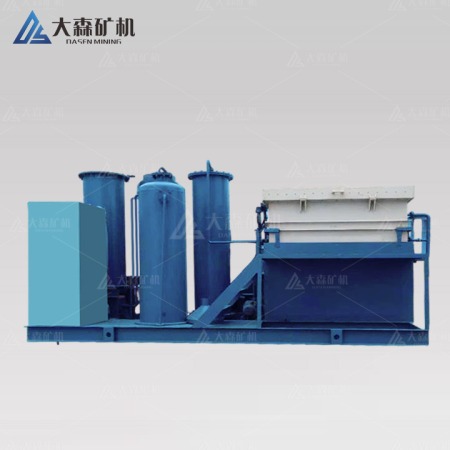

Composition: A deoxygenation tower typically consists of a tower body, tower cover, liquid ejector, packing material, liquid level control device, and tubular liquid level gauge.

Application: In the context of cyanidation beneficiation, vacuum deoxidation towers play a crucial role in purifying precious metal solutions. These towers operate by removing dissolved oxygen, a substance that can adversely affect the zinc replacement process in gold recovery.

Deoxygenation towers are the industry standard for removing oxygen from liquids. These cylindrical structures feature a cone-shaped bottom and a bolted upper section. Inside, a solution sprayer is positioned near the top, while the middle section is filled with polypropylene tape braided mesh packing. This packing, supported by steel welded supports and sieve plates at the bottom, maximizes contact between the liquid and the atmosphere, facilitating oxygen removal. To maintain optimal liquid levels, a control device adjusts the liquid inlet valve based on liquid height.

Working Principle of a Deoxygenation Tower

Deoxygenation towers operate under vacuum conditions. Liquid solutions are drawn to the tower’s top, atomized by a sprayer, and evenly distributed across the packing material. The dissolved gases within the liquid are removed through downward flow facilitated by the vacuum. The deoxygenated liquid is collected at the tower’s bottom and pumped out for further processing.

To achieve an oxygen content below 0.5g/m³ and a deoxygenation efficiency exceeding 95%, a gauge pressure of 0.005 to 0.011 MPa is maintained within the tower. Deoxygenation towers must have a minimum height of 3 meters as per specifications.

Water jet pumps are commonly employed to generate the required vacuum for deoxygenation towers.

Product Advantages

The deoxygenation tower is a critical component in cyanide beneficiation, tasked with purifying precious metal-bearing solutions. Dissolved oxygen within these solutions can hinder the zinc replacement process during gold cyanidation, necessitating its removal.

Deoxygenation towers provide an ideal environment for eliminating dissolved oxygen. Our company has developed a novel plastic mesh filler to address the shortcomings of traditional point wave fillers, which can impair deoxygenation efficiency in alkaline cyanide solutions due to calcium formation.

| Specification | Handing medium | Working temperature | Capacity of spraying(m3/h) | Weight(kg) |

| φ7000*3000 | Cyanide liquor | Normal temperature | 16-37.5 | 550 |

| φ1000*3000(3500) | Cyanide liquor | Normal temperature | 16-37.5 | 700(774) |

| φ1400*1400 | Cyanide liquor | Normal temperature | 16-37.5 | 2304 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]