Investigation of tin-tantalum-niobium deposits mining in Nigeria

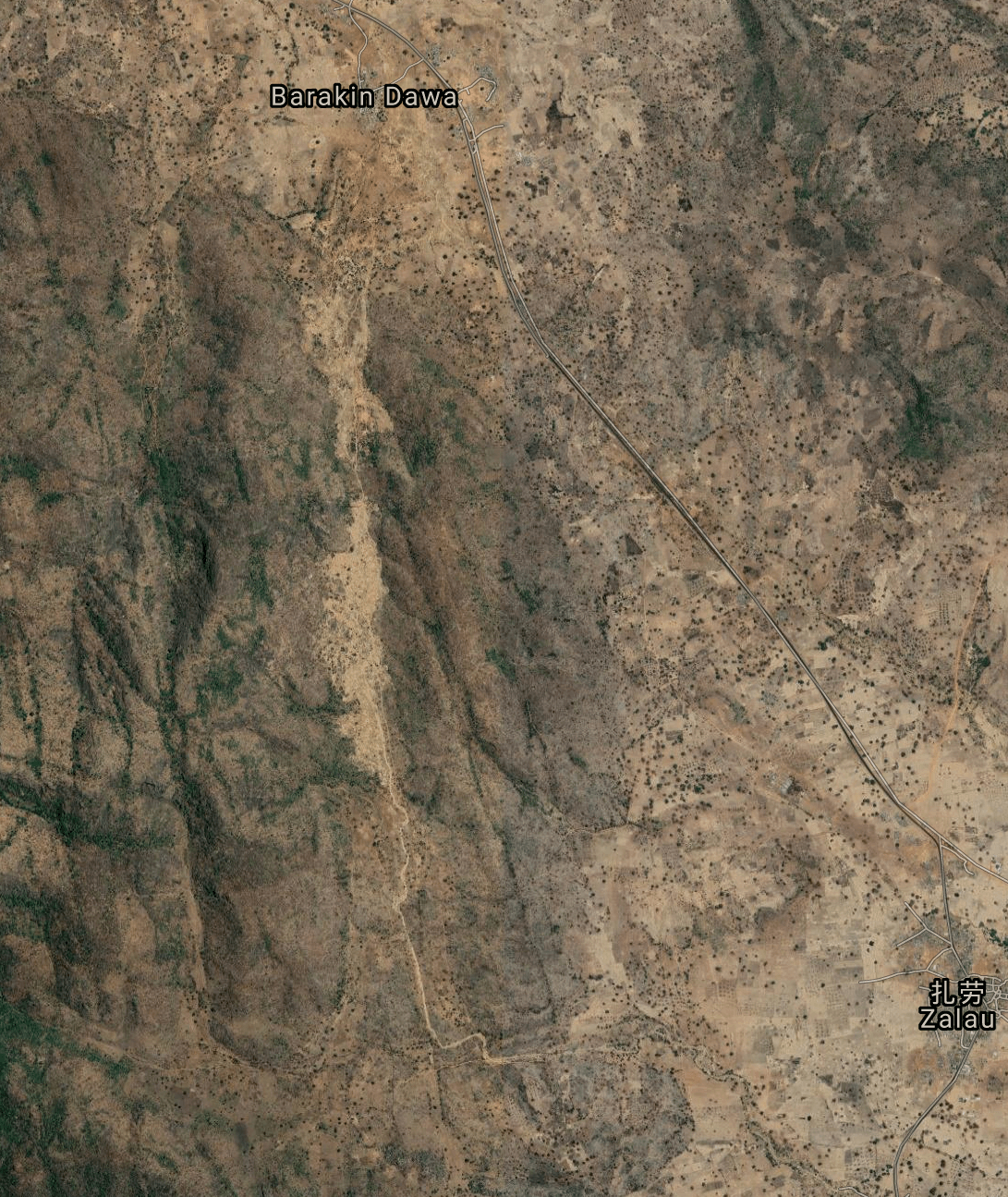

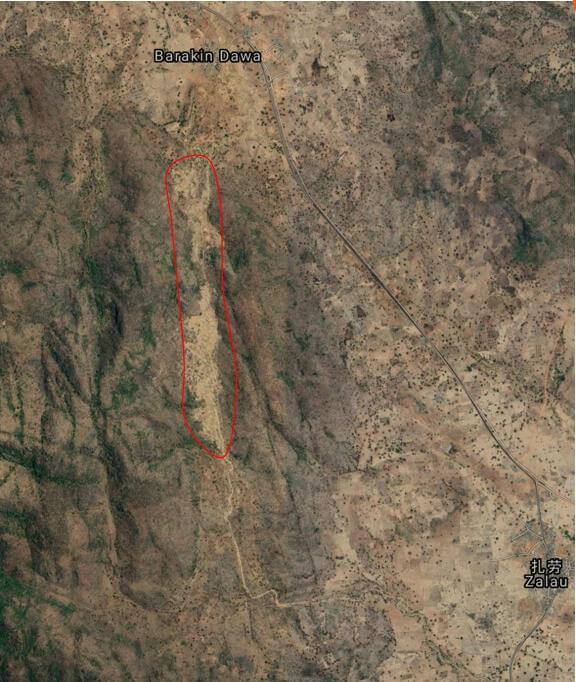

Nigeria, often recognized for its vast oil reserves, is emerging as a significant player in the global mining industry, particularly in the extraction of tin and lithium. The country’s unique geological features, particularly the Barakindawa granite weathering crust type Tin, tantalum, niobium deposit, present a lucrative opportunity for international miners seeking to diversify their portfolios and capitalize on the growing demand for these critical minerals.

Geological Overview

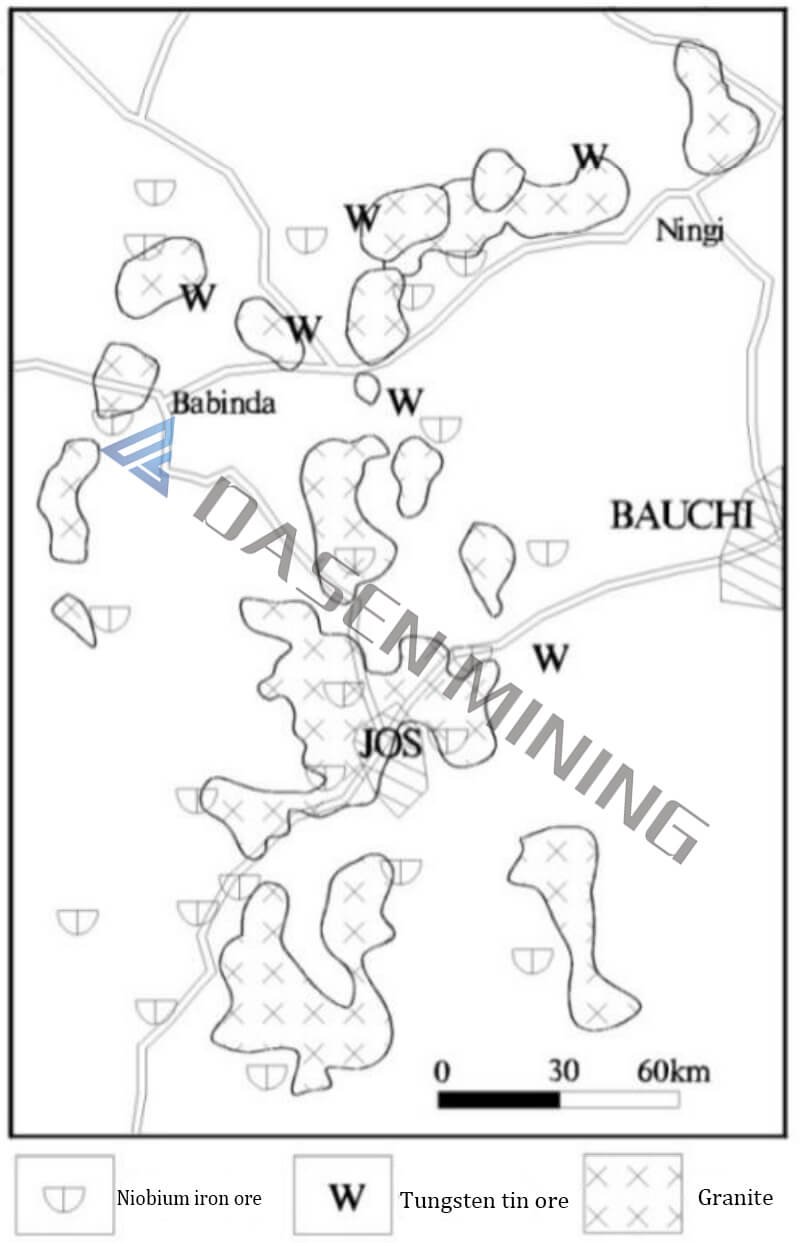

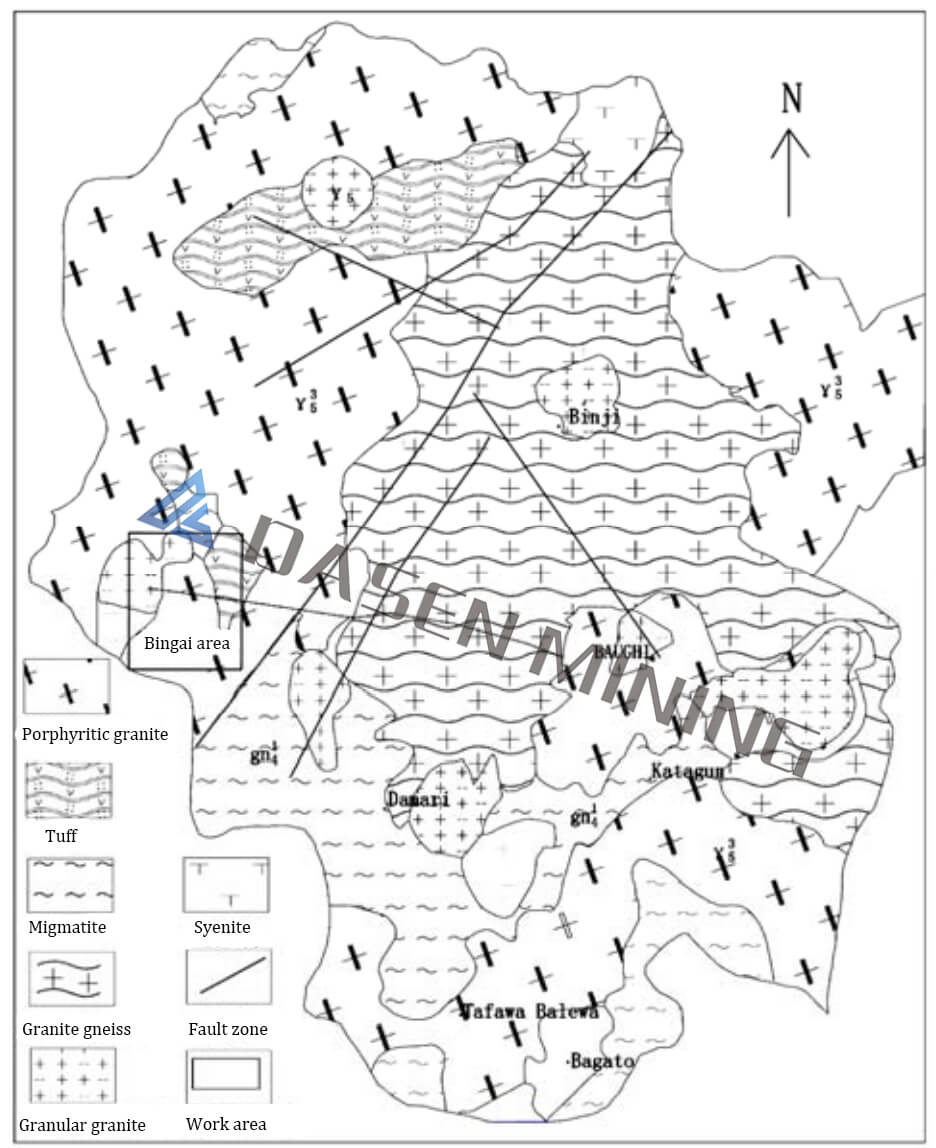

The Jos Plateau, located in central Nigeria, is a geological marvel characterized by its Precambrian and Mesozoic granitic intrusions. This region is a hotspot for mineral deposits, including tin (cassiterite), niobium, tantalum, and lithium. The plateau’s geological history, marked by extensive magmatic intrusions, volcanic activity, and metamorphism, has resulted in a rich endowment of metal ores.

Key geological features include:

Granitic Intrusions: The plateau is dominated by Precambrian coarse-grained porphyritic biotite granites and Jurassic granular biotite granites. These intrusions have undergone significant metamorphism, leading to the formation of various mineral deposits.

Fault Systems: The region is crisscrossed by major fault lines, such as the Northeast Gumau Worji fault and the Zuku Takalafia fault, which have played a crucial role in the emplacement of mineral-rich granitic bodies.

Weathering Crust: The top of the cassiterite-bearing granite is characterized by a weathering crust that hosts the majority of the ore bodies. This crust is a result of prolonged weathering processes that have concentrated valuable minerals.

Tin and Lithium Deposits

The tin deposits in Nigeria are primarily found in the form of cassiterite, which occurs as quartz veins and sulfide ores. These deposits are often associated with other valuable metals such as niobium, tantalum, tungsten, and titanium. The presence of lithium in the region further enhances its attractiveness, as lithium is a critical component in the production of batteries for electric vehicles and energy storage systems.

mining in Nigeria

Key characteristics of the deposits include:

Ore Body Dimensions: The surface ore body has an exposed length of approximately 3,000 meters and a width ranging from 50 to 300 meters, with an average width of about 100 meters. The thickness of the weathering crust, and consequently the ore body, is yet to be fully explored.

Ore Quality: The cassiterite content in the ore is estimated to be around 0.6 kg/m³, with the potential for higher concentrations in unexplored areas. The ore is often accompanied by tungsten (W), niobium (Nb), tantalum (Ta), and titanium (Ti).

Geological Structures: The ore bodies are typically lenticular in shape, with mineralization occurring in both earthy and semi-loose forms.

Tin Processing Opportunities

For global miners, the opportunity in Nigeria extends beyond mining to include tin processing. The country offers a strategic location for establishing processing plants that can add value to the extracted minerals. A 50 Ton Per Hour Tin Ore Processing Plant in Nigeria could be a game-changer, providing the following benefits:

Cost Efficiency: Proximity to the source of raw materials reduces transportation costs and enhances operational efficiency.

Market Access: Nigeria’s strategic location provides easy access to both African and global markets.

Economic Incentives: The Nigerian government offers various incentives to attract foreign investment in the mining sector, including tax breaks and streamlined regulatory processes.

Environmental and Sustainability Considerations

As global miners face increasing pressure to adopt sustainable practices, Nigeria presents an opportunity to implement environmentally friendly mining and processing techniques. The development of a 50 Ton Per Hour Tin Ore Processing Plant can incorporate the latest technologies to minimize environmental impact, such as:

Water Recycling Systems: Implementing closed-loop water systems to reduce water usage.

Dust and Emissions Control: Utilizing advanced filtration systems to minimize air pollution.

Waste Management: Developing comprehensive waste management plans to ensure responsible disposal of tailings and other by-products.

mining in nigeria

Work suggestion:

| Using RC drill or DD drill, according to the spacing of 80 × 80m, the depth is controlled by the side, and the available resource reserves are submitted according to the specification requirements. |  |

Nigeria’s tin and lithium mining potential is a compelling proposition for global miners. The Barakindawa granite weathering crust type deposit offers a unique opportunity to tap into a rich vein of valuable minerals, while the establishment of a 50 Ton Per Hour Tin Ore Processing Plant presents a strategic advantage for those looking to capitalize on the growing demand for these critical materials. With the right approach to sustainability and environmental stewardship, miners can unlock the full potential of Nigeria’s mining sector and secure a prosperous future in this dynamic market.

50 Ton Per Hour Tin Ore Processing Plant in Nigeria

. For more knowledge about mineral processing, please follow us. or contact us:

Whatsapp:+86 133 1927 7356

Email:[email protected]