Hydrocyclone Pressure Settings: How to Optimize Yours

Hydrocyclones are essential pieces of equipment in many industries, from mining to wastewater treatment. Their effectiveness largely hinges on a critical factor: pressure settings. By understanding the role of pressure in hydrocyclone operation, you can optimize your process, improve separation efficiency, and extend the lifespan of your equipment.

Why Pressure Matters

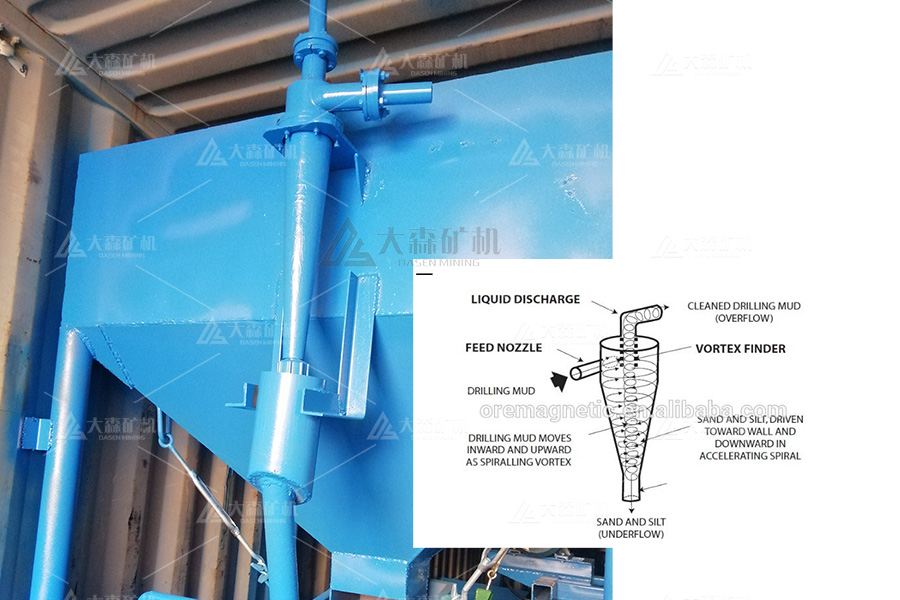

The pressure within a hydrocyclone directly affects the centrifugal force exerted on the particles suspended in the fluid. This force is crucial for separating particles based on their size and density.

- Too much pressure: Can lead to excessive wear and tear on the equipment, as well as inefficient separation.

- Too little pressure: May result in poor separation efficiency and reduced throughput.

Factors Affecting Optimal Pressure

Several factors influence the ideal pressure setting for a hydrocyclone:

- Material properties: The density, size, and shape of the particles being separated.

- Equipment design: The dimensions and geometry of the hydrocyclone itself.

- Feed rate: The volume of material being processed.

- Desired separation: The cut point, or the size at which particles are separated.

The Sweet Spot: Finding the Right Pressure

While there’s no one-size-fits-all answer, a typical pressure range for hydrocyclones is between 2 and 5 bar. However, it’s essential to fine-tune this setting based on your specific application.

Tips for Adjusting Pressure

- Start low: Begin with a lower pressure and gradually increase it until you achieve the desired separation.

- Monitor performance: Continuously assess the quality of the underflow and overflow to ensure optimal separation.

- Consider other factors: Factors like feed concentration and feed rate can also impact pressure requirements.

Conclusion

Proper pressure settings are vital for achieving maximum efficiency and longevity from your hydrocyclone. By carefully considering the factors that influence pressure and following these guidelines, you can optimize your separation process and improve overall system performance.

Whatsapp:+86 133 1927 7356

Email:[email protected]