How to Process Sulphide–Oxide Gold Ore in Iran?

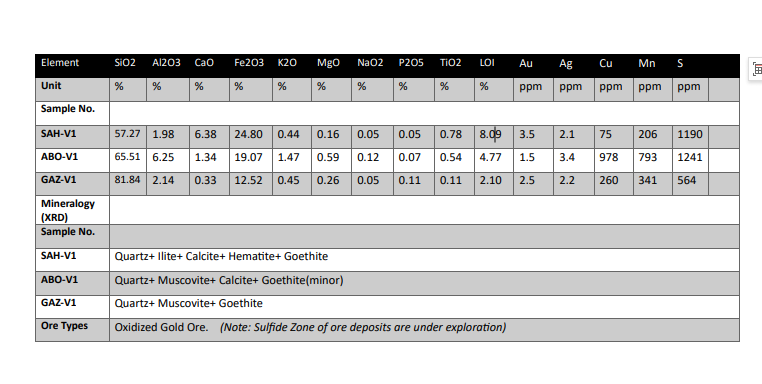

A recently reviewed Iranian ore displays a mixed sulphide–oxide gold system with notable Ag, Cu, Mn, and S. Head grades of 1.0–3.5 ppm Au are moderate but commercially attractive when paired with a disciplined flowsheet. To fast-track deployment and control costs, we propose a containerized CIL/CIP leaching plant.

Why a containerized plant?

- Accelerated delivery and commissioning through factory-built, pre-tested modules

- Scalable capacity by adding containers as ore supply grows

- Consistent quality, instrumentation, and safety standards

- Compact footprint with reduced civil works—suited to remote sites

Ore characteristics and implications

- Elevated S and Cu increase cyanide and lime consumption and can compete for carbon sites

- Robust oxygenation is required to sustain leach kinetics in sulphidic matrices

- Selective copper management (e.g., SART) can improve gold recovery and reduce OPEX

We recommend pre-production lab and pilot work to confirm:

- Cyanide/lime consumption and target pH (10.5–11.0)

- Leach kinetics versus grind size and oxygen regime

- Copper and sulfur deportment

- Carbon loading, fouling, and regeneration conditions

- Detox requirements for tailings and effluent

- Crushing and milling

- Primary crushing and ball milling to an optimized P80 of 75–106 μm, confirmed by kinetics testing

- Thickening

- High-rate thickener to 40–50% solids by weight to reduce tank volume and enhance kinetics

- Cyanide leaching with carbon (CIL/CIP)

- Controlled pH and cyanide addition with air/oxygen sparging

- Approximate 48-hour residence to achieve the first batch of loaded carbon

- Carbon handling and gold recovery

- Interstage screening, Zadra or AARL elution, electrowinning, and doré smelting

- Carbon reactivation via kiln to maintain adsorption performance

- Copper and reagent management

- Staged cyanide dosing and lime for stability and HCN suppression

- SART where soluble copper is significant to precipitate Cu as sulfide and recycle cyanide

- Lead nitrate dosing as warranted by testwork to accelerate kinetics

- Tailings and environmental stewardship

- Tailings thickening and cyanide detox (SO2/air, peroxide, or Caro’s acid)

- Monitoring of WAD cyanide and residual Cu to meet environmental standards

Containerized plant configuration

- ISO-container modules for:

- Crushing–milling and classification

- Thickening with flocculant preparation

- Leach/CIL/CIP tankage with agitators and interstage screens

- Elution–electrowinning–smelting

- Reagents, water, air/O2, MCC/PLC controls

- Optional assay lab and carbon regeneration

- Site needs: level pad, power, raw water, kiln/boiler fuel, and compliant tailings storage

Performance snapshot

- Head grade: 1.0–3.5 ppm Au (rock gold)

- Leach density: 40–50% solids by weight

- Residence: ~48 hours to first carbon harvest; finalize via pilot testing

- Expected recovery: typically 75–90% with proper grind, oxygenation, and copper control

Testwork program

- Mineralogy (QEMSCAN/MLA), head assays (Au, Ag, Cu, S, Fe, Mn)

- Grind–leach optimization across PSD bands

- Reagent screening for cyanide, lime, oxygen, lead nitrate

- Carbon isotherms and fouling/attrition assessment

- SART amenability and detox verification

Why Dasen Mining?

- Over 30 years in gold recovery with international project delivery

- Proven containerized CIL/CIP plants tailored to mixed sulphide–oxide ores

- End-to-end support: sampling, lab/pilot, flowsheet design, manufacturing, installation, commissioning, and operator training

- Ongoing optimization: reagent audits, carbon management, and remote monitoring?

Whatsapp:+86 133 1927 7356

Email:[email protected]