Advanced Flotation Techniques for Refractory Copper Oxide Ores

Oxide ores, characterized by their oxidized mineral content, present unique challenges in the mining industry. Their complex structure, variable properties, and the presence of slime and soluble salts necessitate specialized flotation techniques. This article delves into the intricacies of oxide ore flotation, exploring the common methods and considerations for achieving optimal results.

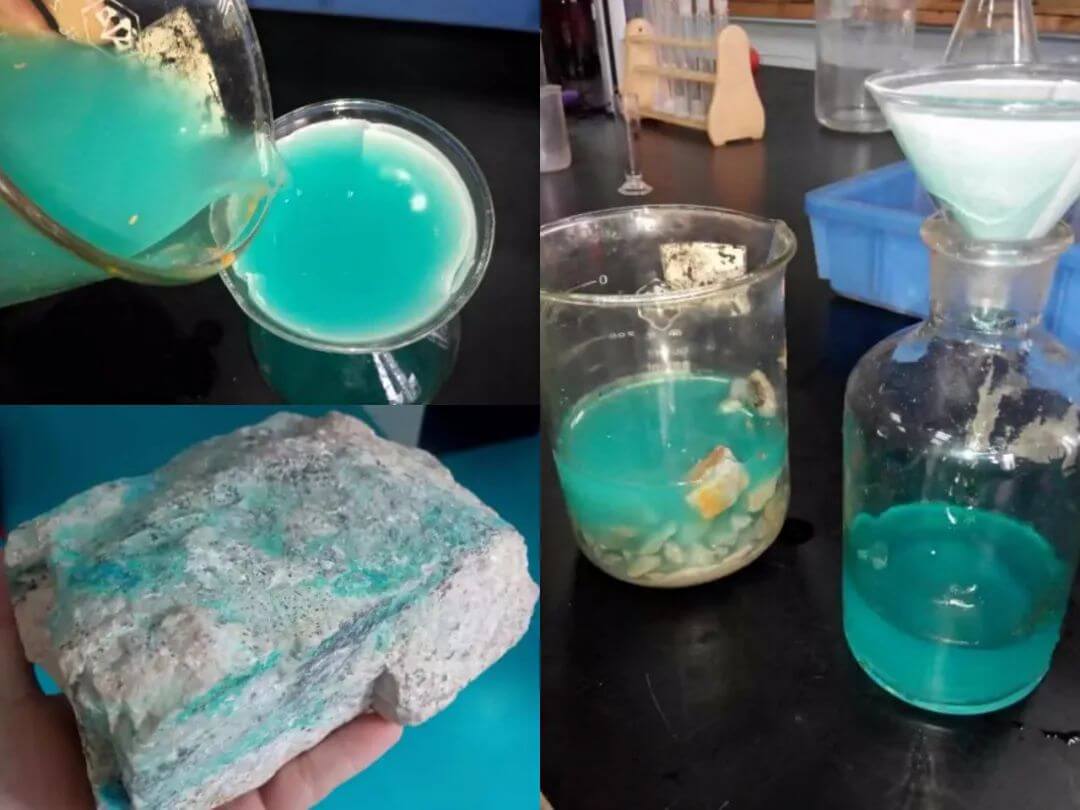

Understanding Oxide Ores

Oxide ores, formed through the natural oxidation of sulfide minerals, are typically less reactive and more difficult to float than their sulfide counterparts. Key characteristics of oxide ores include:

- Complex Structure: Disseminated particles often exhibit fine sizes and intricate structures, making them challenging to liberate.

- Variable Properties: The properties of oxide ores can vary significantly between deposits and even within a single deposit.

- High Slime Content: The presence of slime can hinder flotation efficiency and selectivity.

- Soluble Salt Content: Soluble salts can interfere with reagent adsorption and negatively impact flotation performance.

Flotation Techniques for Oxide Ores

Sulfidation

- Process: The most common method, sulfidation involves converting oxide minerals into sulfide minerals through the addition of sodium sulfide. This process enhances the floatability of the ore, making it amenable to xanthate flotation.

Considerations: Careful control of sulfidation conditions is crucial to achieve optimal results. Excessive sulfidation can lead to over-sulfidation and decreased selectivity.

Organic Acid FlotationProcess: Organic acids and their soaps can be used as collectors for oxide minerals, particularly malachite and azurite. This method is effective when gangue minerals do not interfere with the flotation process.

Considerations: The selectivity of organic acid flotation can be compromised in the presence of carbonate minerals or other interfering gangue components.

Leaching-Precipitation-FlotationProcess: In this method, oxide minerals are leached with sulfuric acid, and the resulting copper ions are precipitated as metallic copper. The precipitated copper can then be floated using conventional flotation techniques.

Considerations: The leaching process can be energy-intensive and may require careful control of pH and reagent dosages.

Ammonia Leaching-Sulfide Precipitation-Flotation

Process: This method is suitable for ores containing alkaline gangue. Ammonia leaching is used to dissolve copper oxide minerals, followed by sulfide precipitation to form copper sulfide. The precipitated copper sulfide can then be floated.

Considerations: Ammonia recovery is essential to minimize environmental impact and reduce operating costs.

Segregation-Flotation

Process: This technique involves chlorination roasting to convert copper oxide minerals into volatile copper chlorides. The chlorides are then reduced to metallic copper, which is adsorbed onto carbon particles and subsequently floated.

Considerations: Segregation-flotation is a high-cost process and is typically used for refractory oxide ores that are difficult to treat by other methods.

- The successful flotation of oxide ores requires a comprehensive understanding of the ore mineralogy, liberation characteristics, and the specific challenges associated with each ore type. By carefully selecting appropriate flotation techniques and optimizing process parameters, it is possible to achieve high recoveries and grades of valuable metals from complex oxide ores.

- We can provide you with more information about copper ore processing. If you have any questions, please contact:Whatsapp:+86 133 1927 7356

Email:[email protected]