How Can Gold Leaching and Zinc Powder Displacement Device Be Optimized in Iran?

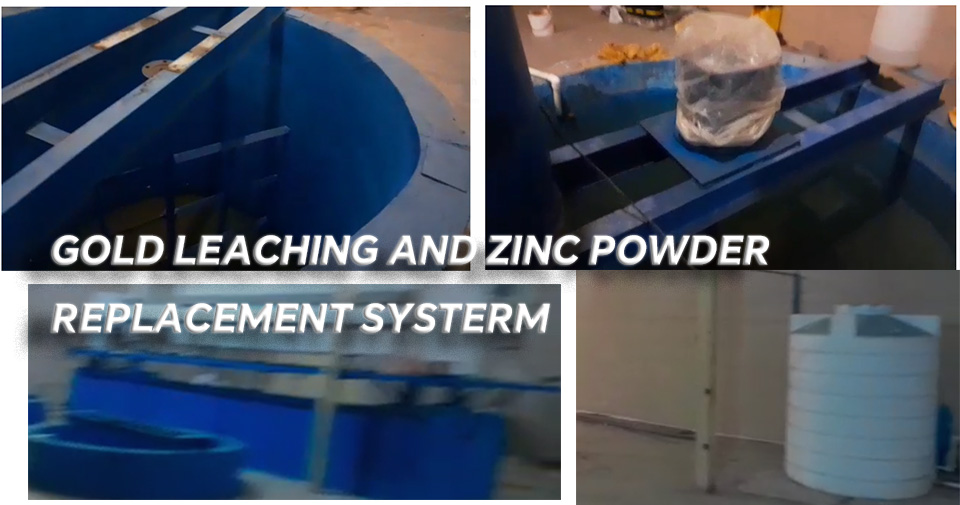

The below pictures depict the gold leaching and zinc powder replacement plant in Iran, which belongs to one of our gold ore leaching customers. This customer is currently employing a process where gold leaching is carried out first, followed by using a press filter to handle the tailings, and then conducting zinc powder replacement. However, the recovery rate has been less than satisfactory, prompting the customer to seek our assistance in enhancing it.

When it comes to such issues, at Dasen, we take a comprehensive approach. We first analyze the customer’s entire ore – processing situation in detail. Our team will conduct thorough assays of the ore to understand its composition accurately. In addition, we will dispatch experienced engineers to the customer’s site. This is where our zinc powder replacement system plant comes into play. Our engineers will assess whether the current Zinc Powder Displacement Device is being used optimally and if it is suitable for the specific ore and leaching process.

In general, the Zinc Powder Displacement Device requires the pregnant solution to be extremely clean. Usually, only heap leaching and pit leaching can meet this requirement, while common full-mud leaching is unable to achieve a sufficiently clean state. In this case, we determined that the existing Zinc Powder Displacement Device-based plant was not suitable for this particular leaching flow.

If we want to solve this problem, we need to consider removing the current zinc powder replacement system plant. Instead, we suggest using activated carbon for desorption during the leaching process. After obtaining the activated carbon loaded with gold, it can be fed into the desorption and electrolysis plant. This process can effectively separate the gold and the activated carbon. The gold can be refined to 99.99% purity, and the activated carbon can be recycled for further use.

Moreover, we always strive to make the most of the customer’s existing on – site equipment. By integrating new processes and technologies with the existing setup, we aim to ensure that the customer can achieve a high – return with a relatively low investment. We understand that every global miner is looking for cost effective solutions without sacrificing the quality and quantity of ore recovery. Our comprehensive analysis, including the evaluation of the zinc powder replacement system, is all part of our commitment to helping our customers reach the highest possible ore recovery rates.

The below is about the desorption and electrolysis plant, you can check it:

If you are interested in this plant too, you can freely contact us.

Dasen Mining Machinery has been working on the gold ore recovery for over 30 years. In this field, we have lots of site processing experience, we did many gold processing projects overseas. Looking forward to your inquiry.

Whatsapp:+86 133 1927 7356

Email:[email protected]