Gold Extraction Using the Zinc Powder Replacement Process

The zinc powder replacement process is a widely used method for extracting gold from cyanide-rich precious solutions. This technique is particularly effective in the final stages of gold refining and is known for its simplicity, low cost, and high efficiency.

Overview of the Gold Extraction Stages

The complete gold extraction process includes six main steps:

Grinding and Classification

Concentration and Dehydration

Leaching and Washing

Precious Liquid Purification

Pregnant Liquid Deoxidation

Zinc Powder Replacement

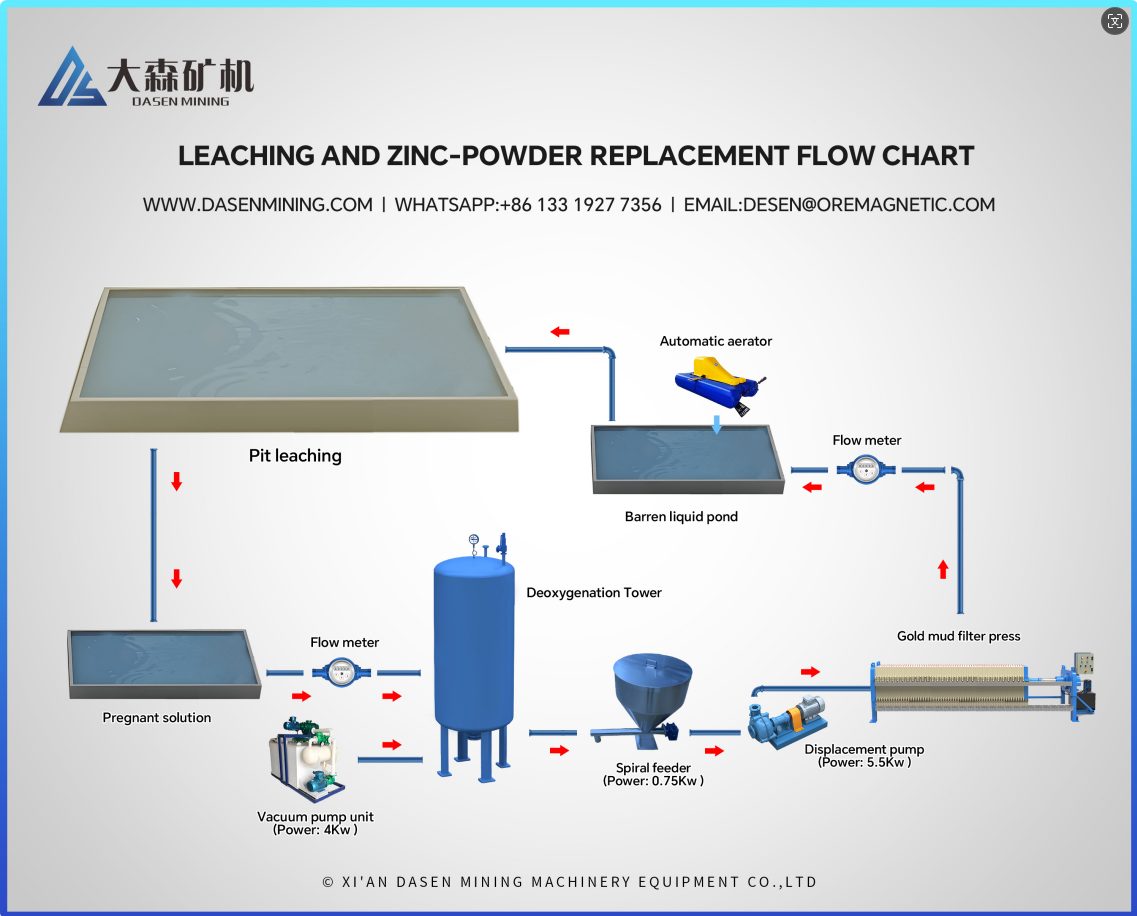

In this article, we focus on the final stages of the process—deoxidation and zinc powder replacement, which occur after leaching.

1. Deoxidation of the Precious Solution

Before zinc is introduced, it is crucial to remove dissolved oxygen from the cyanide gold solution. Oxygen can interfere with the replacement reaction, reducing efficiency and increasing zinc consumption.

We use a vacuum deoxidation tower to eliminate oxygen from the solution. This step ensures optimal conditions for the zinc-gold replacement reaction and prevents unwanted side reactions.

2. Zinc Powder Replacement

Once the solution is purified and deoxygenated, zinc powder is introduced to initiate the replacement reaction. Gold ions in the solution are reduced and replaced by zinc, forming gold mud (solid gold particles).

⚠️ Important Considerations:

Zinc dosage must be carefully controlled.

The process should be executed quickly to prevent zinc oxidation and agglomeration.

To ensure precision, modern systems use automatic zinc powder feeders and zinc slurry mixing devices, reducing the need for manual handling.

Gold Mud Collection and Filtration

In our processing plant, we use a gold mud filter press to separate the gold mud efficiently. This equipment simplifies the operation, improves recovery rates, and reduces labor intensity.

The collected gold mud is then sent to the smelting stage to produce pure gold.

Our Experience

At DASEN MINING, we have extensive experience in designing and implementing gold extraction systems using the zinc powder replacement process. We have successfully completed multiple turnkey projects and offer complete support from design to commissioning.

If you’re interested in this gold extraction method or need guidance on building your own plant, please feel free to contact our team. We are happy to assist you.

Whatsapp:+86 133 1927 7356

Email:[email protected]