How to Improve Tungsten Tailings Recovery Rate Using Shaking Tables

Recently, our company exported a batch of shaking tables to India. We conducted a thorough investigation upon receiving feedback from a tungsten tailings processing plant regarding low recovery rates with their existing 6S shaking tables.

Understanding the Problem

After carefully analyzing the client’s current mineral processing technology and equipment configuration, we determined that while using 6S shaking tables was appropriate, the primary issue was a mismatch between the shaking table’s riffle shape and the particle size distribution of the ore. Additionally, the client was not implementing a scavenging process for the tailings, resulting in significant economic losses.

The Solution

Our engineers conducted extensive testing and research to develop a tailored solution. By optimizing the riffle shape to match the specific characteristics of the tungsten ore, we significantly improved the recovery rate. Furthermore, we recommended implementing a scavenging process to recover additional valuable minerals from the tailings.

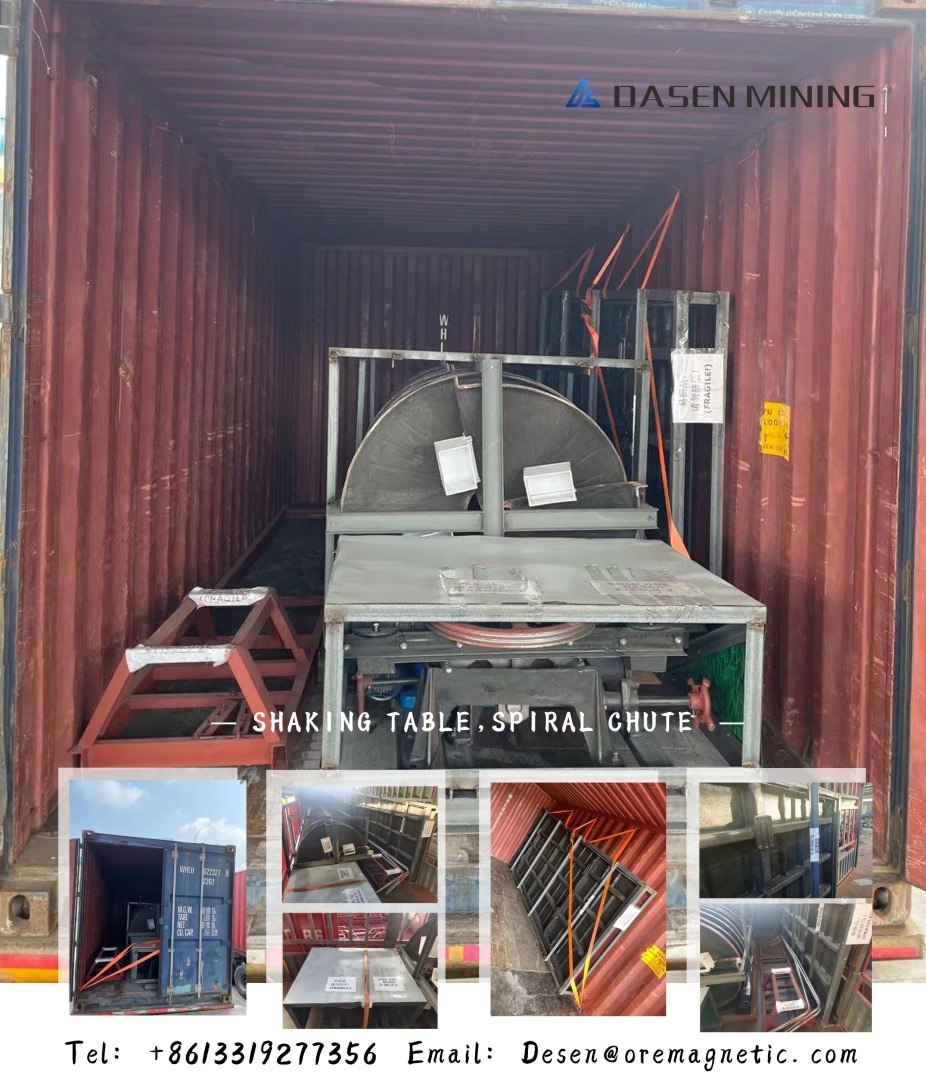

Our recent shipment of shaking tables to India highlights the global demand for efficient and reliable mineral processing equipment. By understanding the unique challenges faced by our clients, we are able to provide customized solutions that maximize recovery and profitability.

Shaking Tables: A Versatile Tool for Mineral Processing

Shaking tables are widely used in the mineral processing industry due to their ability to separate minerals based on density and particle size. The table’s vibrating deck causes particles to spread diagonally from the feed trough and discharge along the edge of the bed surface. This process allows for the production of multiple products with varying grades, such as concentrate, middlings, and tailings.

Key Benefits of Shaking Tables:

High enrichment ratio: Shaking tables are highly efficient at concentrating valuable minerals.

Versatility: They can be used to process a wide range of minerals, including gold, chromium, manganese, tin, tantalum-niobium, and zircon.

Accuracy: Shaking tables can produce products with precise grades.

Whatsapp:+86 133 1927 7356

Email:[email protected]