Gold Ore Processing Project in the Philippines

Project Overview

The image above shows gold ore from a mining site in the Philippines. Initial visual inspection suggested a high content of silver, zinc, and lead, indicating that flotation could be an effective processing method. However, on-site beneficiation testing confirmed that the gold ore can also be efficiently recovered using the leaching method.

Customer’s Processing Strategy

The customer aims to recover gold using a 150TPD Gold CIL Plant (Carbon-in-Leach) in the future. However, due to current budget constraints, they have decided to begin with a more cost-effective gravity separation process.

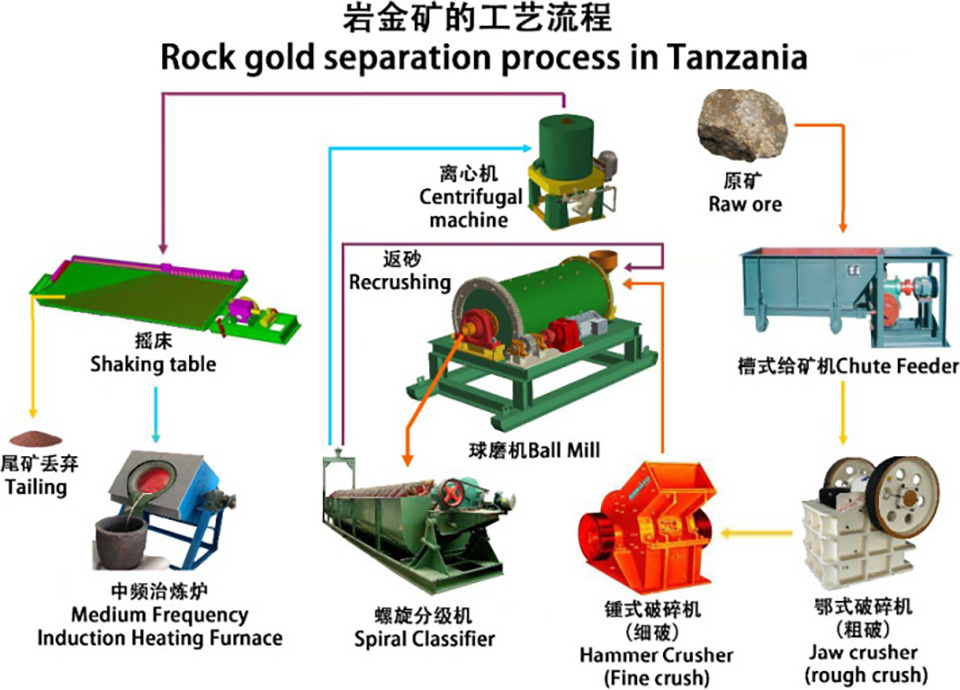

Initial Processing Flow

- Crushing

- Grinding

- Gravity Separation (Shaking Table)

By applying grinding and gravity separation, the customer plans to recover gold concentrate and generate initial revenue. Once sufficient funds are available, they intend to invest in building the full-scale Gold CIL Plant.

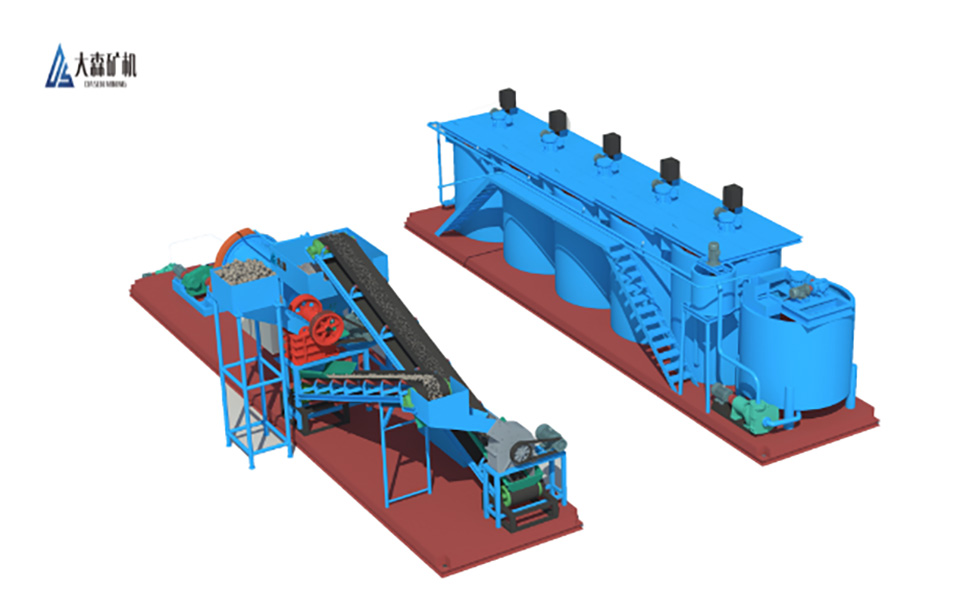

Container-Type Gold Leaching Plant

We offer a container-type gold leaching plant designed for fast and easy deployment. All essential equipment is pre-installed within containers, enabling rapid setup at the ore site without the need for complex installation work.

Key Features:

- All equipment pre-installed in containers

- Minimal on-site installation required

- Fast and efficient gold leaching process

Why Choose Dasen Mining Machinery?

With over 30 years of experience in gold ore recovery and mineral processing, Dasen Mining Machinery has completed numerous gold processing projects worldwide. Our expertise ensures reliable equipment solutions and efficient project delivery.

Whatsapp:+86 133 1927 7356

Email:[email protected]