Ilmenite, Moanzite, Zircon processing in Nigeria

These pictures are from one customer from Nigeria. In this material, it contains iron, ilmenite, monazite, niobium, and zircon. This material is the customer buying from others.

Content:

the ilmenite content in this material is 30-40%

His purpose:

Get the high-grade TiO2 and very low Fe as the priority, then extract other minerals— zircon, monazite, and niobium if possible.

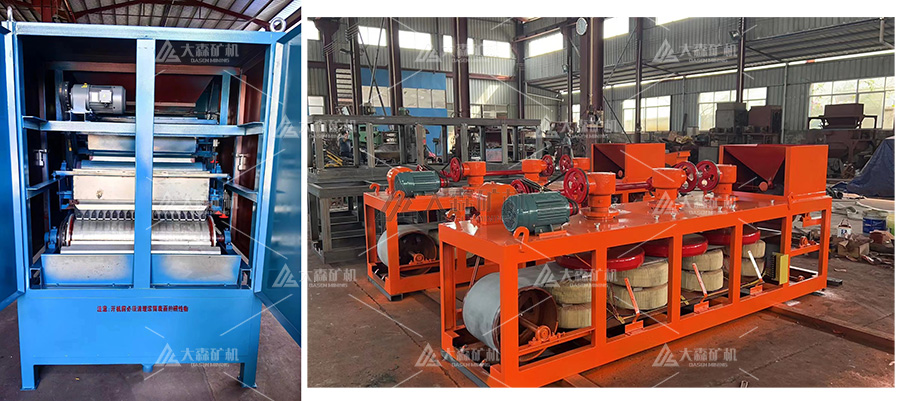

Generally, we use the 3 rollers’ magnetic separator and 3 discs’ electromagnetic separator for such ore.

The three-roller magnetic separator has three rollers: the first one can remove iron, the second one can separate ilmenite(45-50% grade), and the third one can separate monazite.

Then, using the 3-disc electromagnetic separator, you can get fine ilmenite, fine monazite(50-60% grade), TaNb(30% + grade), zircon, and tin.

This customer checked the magnetic separators in our Jos warehouse yesterday, we will talk today about this.

This customer plans to lease a warehouse on Jos- Bauchi Road, which will also make it convenient for us to inform him about the machine when he uses it.

If your ore is also like this, and you want to get more valuable minerals from it, you can contact us to do the best design.

Dasen Mining Machinery has been working on magnetic intensity minerals recovery for over 30 years. In this field, we have lots of site processing experience, we did many processing projects in Nigeria. We have a warehouse in Jos, if you are interested at any time, you can contact us freely.

Whatsapp:+86 133 1927 7356

Email:[email protected]