How to Separate Alluvial Type Monazite?

Monazite is a reddish-brown phosphate mineral rich in rare-earth elements. It is often found in small, isolated crystals and has a hardness of 5.0 to 5.5 on the Mohs scale. The mineral is relatively dense, with a density ranging from 4.6 to 5.7 g/cm³. Monazite is typically found mixed with other minerals such as tin, columbite, ilmenite, and zircon sand, especially in regions like Nigeria.

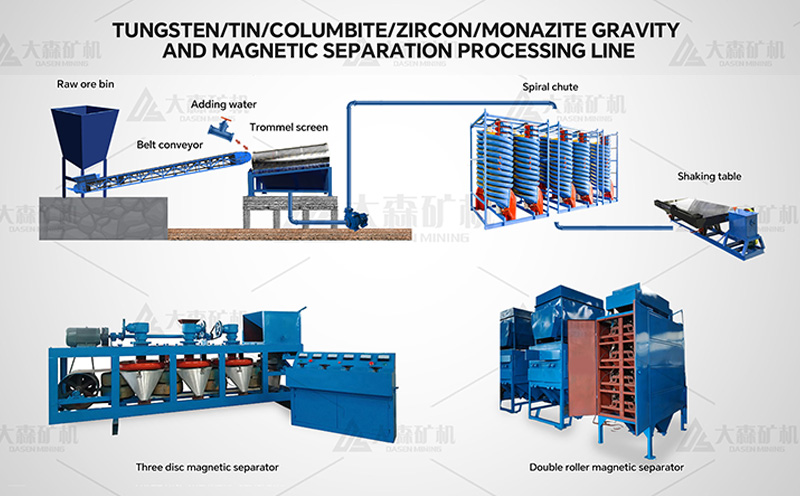

For Nigeria monazite,usually mix with tin,columbite,ilmenite,zircon sand etc… After almost 10 years of project experience for separation alluvial tin,columbite,ilmenite,zircon sand, monazite, we made below processing line for your reference:

Step-by-Step Process for Separating Alluvial Monazite

Washing:

Equipment Used: Screw washers, trommel screens, and vibrating screens.

Purpose: To remove stones, clay, and mud from the raw material.

Gravity Separation:

Equipment Used: Jig machines, spiral chutes, and shaking tables.

Purpose: To obtain rough and fine concentrates of the minerals.

Magnetic Separation:

Equipment Used: Both wet and dry magnetic separators.

Purpose: To separate iron and ilmenite from the mixture.

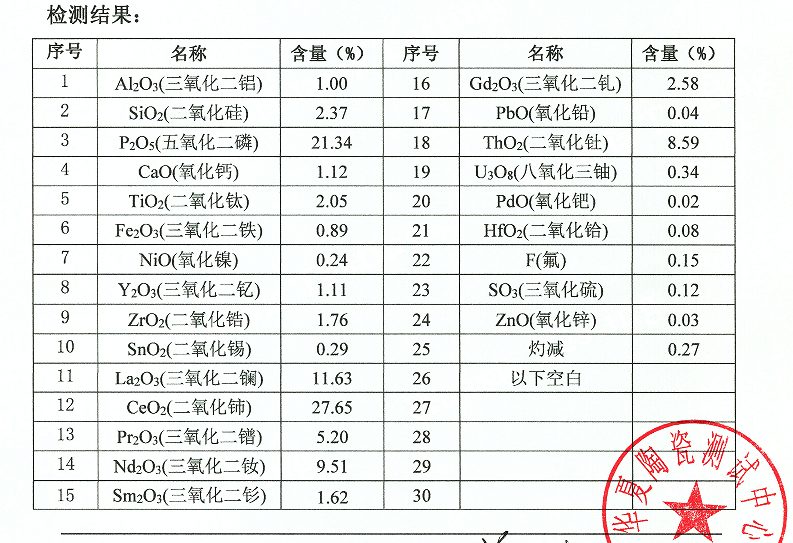

After the raw material processed on this line, we can get the monazite by local magnetic test 90% above, and when the sample send to China for testing, we will get the result like below.

Detailed Insights

Magnetic Separation: Monazite can be isolated as a nearly pure concentrate using gravity, magnetic, and electrostatic separation methods. The magnetic intensity can be controlled to achieve the separation of ilmenite and monazite.

Gravity Separation: This method is effective for separating monazite from other heavy minerals. It involves the use of equipment like jig machines and spiral chutes to concentrate the monazite.

Electrostatic Separation: This technique is also employed to further purify the monazite concentrate.

Dasen Mining’s Expertise

Dasen Mining, founded in the 1990s, has over 30 years of experience in mineral separation. The company specializes in:

Ore analysis

Beneficiation experiments

Processing line design

Equipment manufacturing

Whole plant installation

Staff training

For monazite processing, Dasen Mining offers a professional engineering team to design the most efficient processing line tailored to specific needs.

By following these steps and utilizing the expertise of companies like Dasen Mining, the separation of alluvial-type monazite can be efficiently achieved, ensuring a high purity of the final product.

Whatsapp:+86 133 1927 7356

Email:[email protected]