What is the cost of setting up a tin ore beneficiation plant?

The cost of setting up a tin ore beneficiation plant can vary depending on the size, complexity, and location of the plant. However, as a general rule of thumb, you can expect to pay between $500,000 and $10 million for a new plant.

Here are some of the factors that can affect the cost of a tin ore beneficiation plant:

- The size of the plant: The larger the plant, the more expensive it will be to build and operate.

- The complexity of the plant: More complex plants will require more equipment and infrastructure, which will drive up the cost.

- The location of the plant: Plants located in remote areas will be more expensive to build and operate due to the cost of transportation and labor.

- The type of beneficiation process: Different beneficiation processes have different capital costs. For example, flotation plants are typically more expensive than gravity concentrators.

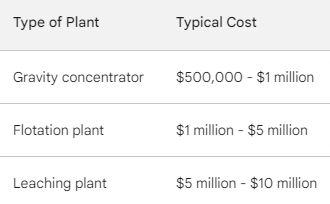

Here is a table of typical costs for different types of tin ore beneficiation plants:

Note: These are just estimates, and the actual cost of a plant will vary depending on the specific circumstances.

In addition to the initial capital cost, there will also be ongoing operating costs for the plant. These costs include:

- Labor: The plant will need to employ operators, technicians, and maintenance staff.

- Energy: The plant will use electricity to power its equipment.

- Chemicals: The plant will use chemicals for flotation, leaching, and other processes.

- Wastewater treatment: The plant will need to treat its wastewater to meet environmental standards.

The operating costs of a tin ore beneficiation plant can be significant, and they will need to be factored into the overall economic viability of the project.

If you have a specific project scope or location in mind, obtaining detailed quotations or engaging in feasibility studies with relevant experts would be a crucial step in determining the actual cost.

Whatsapp:+86 133 1927 7356

Email:[email protected]