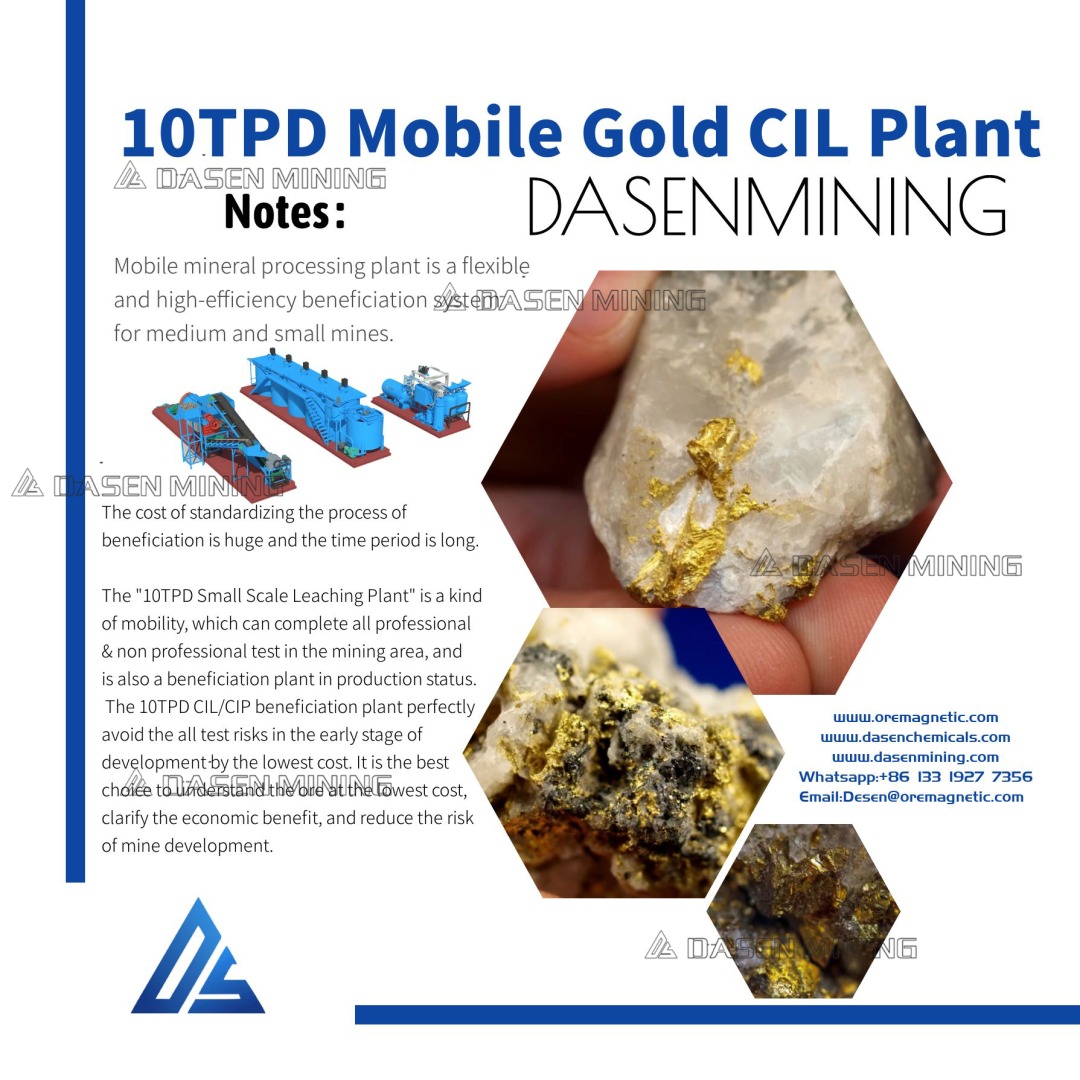

Typical 10TPD Mobile Gold CIL Plant

A 10TPD Mobile Gold CIL Plant is a compact and portable gold processing plant that can be used to extract gold from ore samples or tailings. It is designed to be easy to transport and set up, making it ideal for small-scale gold mining operations or use in remote locations.

Processing Capacity

The plant has a processing capacity of 10 tons per day (TPD), which means it can process up to 10 tons of ore per day. This capacity can be adjusted based on the client’s needs and the type of ore being processed.

Process Flow

The process flow of a 10TPD Mobile Gold CIL Plant typically includes the following steps:

- Crushing and grinding: The ore is crushed and ground into a fine pulp to increase the surface area of the gold and allow it to be dissolved more easily.

- Leaching: A solution of cyanide and water is added to the pulp, and the mixture is agitated and aerated to allow the gold to dissolve.

- Separation: The gold-bearing solution is then separated from the pulp using a series of chemical reactions and physical processes.

- Electrowinning: The gold is then recovered from the solution using electrowinning, which involves passing an electric current through the solution to deposit the gold onto an electrode.

- Smelting: The gold is then smelted to produce a gold bar or other final product.

Equipment

A 10TPD Mobile Gold CIL Plant typically includes the following equipment:

- Crushing and grinding equipment: A jaw crusher, ball mill, and other equipment are used to crush and grind the ore.

- Leaching equipment: A series of tanks and pumps are used to mix the ore with the cyanide solution and aerate it.

- Separation equipment: A series of filters, centrifuges, and other equipment are used to separate the gold from the solution.

- Electrowinning equipment: An electrowinning cell is used to recover the gold from the solution.

Whatsapp:+86 133 1927 7356

Email:[email protected]