How Rotary Spiral Chutes Optimize Mineral Recovery and Improve Efficiency

Heavy mineral concentrate processing is a crucial step in mining operations, and the choice of equipment can significantly impact efficiency and recovery rates. Rotary spiral chutes have emerged as a valuable tool for this task, offering several key advantages.

How Rotary Spiral Chutes Optimize Mineral Recovery

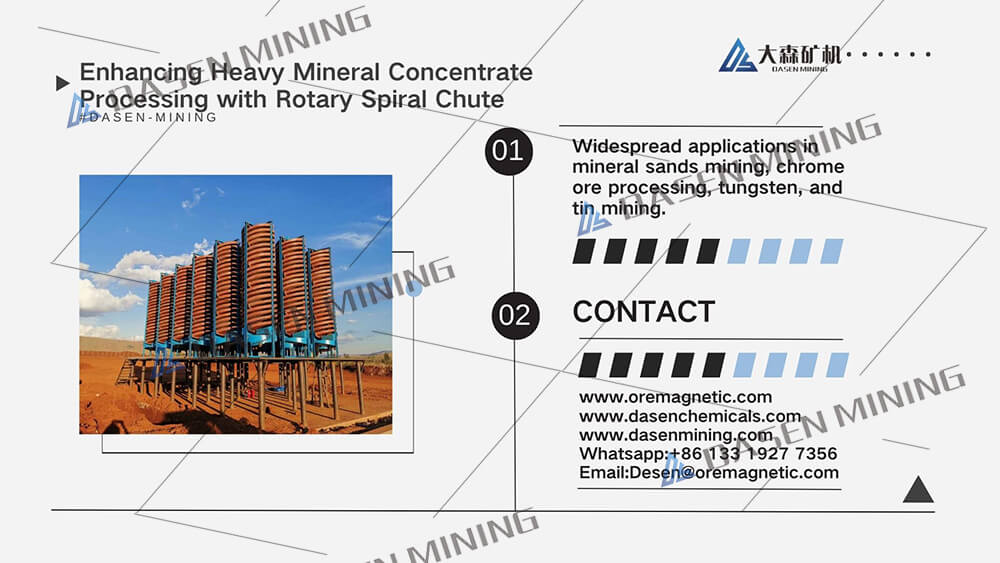

Rotary spiral chutes excel in separating heavy minerals from lighter materials. Their unique design, involving a rotating spiral channel, creates a centrifugal force that effectively segregates particles based on density. This mechanism leads to higher recovery rates and reduced manual labor requirements compared to traditional gravity separation methods.

Key Benefits of Using Rotary Spiral Chutes

- Enhanced Recovery Rates: The spiral motion and centrifugal force maximize the separation of heavy minerals, resulting in higher yields.

- Efficient Processing: Rotary spiral chutes enable continuous and automated operations, boosting productivity and reducing downtime.

- Space-Saving Design: Their vertical configuration makes them ideal for plants with limited space, optimizing utilization of available area.

- Versatility: These chutes can handle a wide range of heavy minerals, including gold, tin, tungsten, and more, making them suitable for various mining projects.

Applications in Heavy Mineral Concentrate Processing

- Mineral Sands Mining: Rotary spiral chutes are widely used to extract valuable minerals like zircon, rutile, and ilmenite from mineral sands.

- Chrome Ore Processing: They help separate chromite concentrates from gangue materials, producing high-quality chromite ore for ferrochrome production.

- Tungsten and Tin Mining: These chutes are essential for efficiently separating heavy minerals from low-grade tungsten and tin ores.

Rotary spiral chutes offer a compelling solution for heavy mineral concentrate processing, delivering enhanced recovery rates, efficient operations, and versatility. By understanding their benefits and applications, mining companies can make informed decisions to optimize their processes and maximize profitability.

Whatsapp:+86 133 1927 7356

Email:[email protected]