Description

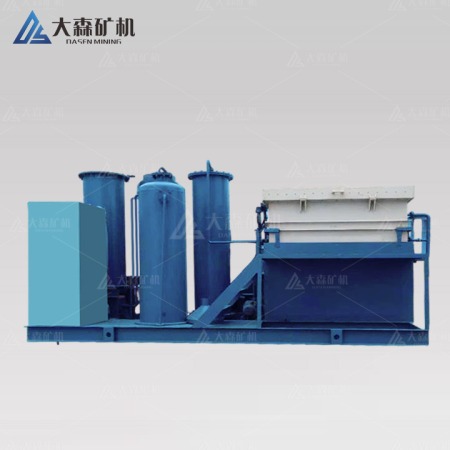

Name: amalgamation cylinder, amalgamation machine, gold amalgam, mercury mixing cylinder

Cylinder size: 420*600mm

Feeding particle size: ≤5mm

Feeding amount per time: 30-50kg

Application field: Widely used internal amalgamation equipment, used to process gold-bearing heavy sand in placer mines and selected gold concentrates in vein gold mines. It is high-efficiency internal gold amalgam equipment.

Uses: Specifically designed for gold and silver mining operations, this equipment utilizes the amalgamation process to extract precious metals from ore.

Amalgamation cylinders, also known as amalgamation machines, are internal mercury mixing devices employed in gold concentrators. These machines boast impressive gold recovery rates, often reaching approximately 90%.

Gravity separation processes primarily yield free gold particles, although these particles frequently exhibit contaminated surfaces. Additionally, some gold exists in compounds with other minerals or gangue. To address these challenges, gravity-separated gold concentrates are fed into amalgamation cylinders. The addition of steel balls to the cylinder facilitates the removal of surface contaminants through grinding, liberating gold particles from their associated materials. The resulting product is a heavy sand containing clean, free gold particles, ready for further processing.

Amalgamation cylinder selection depends on the concentrate’s characteristics. For lighter concentrates, a lightweight amalgamation cylinder with fewer grinding balls is typically used. Heavier sand concentrates with agglomerated particles and significant gold particle contamination often require a heavy-duty cylinder.

The mercury mixing cylinder is a core component of internal amalgamation systems. Rubber-lined, it enhances gold recovery through a grinding process. The impact of the grinding balls disrupts gold particle surfaces, removing contaminants and promoting amalgamation. This forced amalgamation method yields high gold recovery rates.

Key Features:

- Stunning aesthetics and reliable operation

- Energy-efficient design for reduced costs

- Significantly decreased mercury consumption for enhanced environmental sustainability

Product Application:

Unlike labor-intensive manual methods, an amalgamation cylinder is a mechanized solution for placer gold extraction. In many remote and underdeveloped gold mining regions, gold purification still relies on hazardous manual amalgamation processes. This traditional method exposes workers and the environment to the severe risks of mercury poisoning. Mercury, a highly toxic substance, evaporates into the air, posing a significant inhalation threat. Additionally, direct skin contact during manual amalgamation increases the risk of mercury absorption. The amalgamation cylinder addresses these critical issues by automating the process, reducing labor requirements, and minimizing human exposure to harmful mercury.

| Item | Technical parameter | unit |

| Cylinder(dia*length) | 420*600 | mm |

| Volume | 75 | L |

| Rotary speed | 48 | R/min |

| Feeding size | <5 | mm |

| Feeding capacity | 30-50 | kg |

| Motor power | 3 | kw |

| Dimensions | 1600*850*1000 | mm |

| Weight | 350 | kg |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]