Description

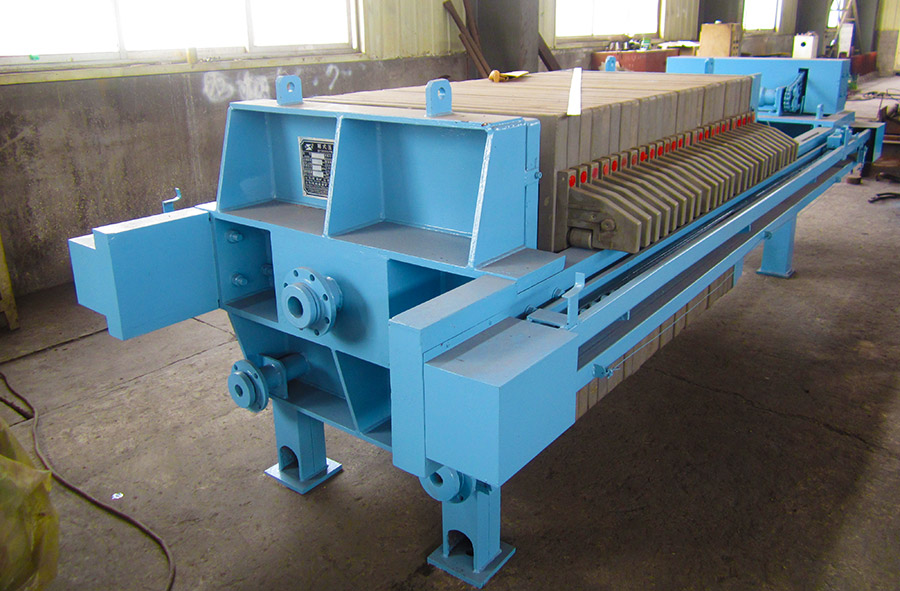

Name: Plate and frame purification tank, Frame filter tank, filter press, cyanide equipment

Filtering area: 45-90 ㎡

Product advantages: no moving parts, convenient operation and maintenance.

Scope of application: it is widely used in the purification section of leaching precious liquid in the replacement process of gold and zinc powder.

Working Principle

A filter press utilizes a filter cloth as the primary medium to separate solids from liquids. The process involves applying vacuum pressure, which draws the clear liquid through the filter cloth. As the liquid passes through, fine particles are captured and retained on the surface of the filter cloth, effectively achieving solid-liquid separation.

Filter press is a specialized unit designed to purify precious liquid before deoxidation in the gold cyanide gold production process.

The frame purification tank removes suspended solid contaminants, such as mud, from the precious liquid through solid-liquid separation. This purification process yields a clarified liquid, enhancing the grade of recovered gold mud, reducing pyrometallurgical smelting costs, and establishing optimal conditions for high-grade gold production.

Renowned for its simple structure, easy maintenance, and user-friendly operation, this equipment allows for alternating cleaning during operation and boasts a long service life. Each filter piece’s liquid collector connects directly to the deoxygenation tower, enabling the tower’s vacuum to draw purified precious liquid for deoxygenation.

| Model | Filtration area (m2) | Volume of cylinder(m³) | Max filtration pressure(Mpa) | weight (kg) |

| BKC-45 | 45 | 5.62 | 100 | 2021 |

| BKC-70 | 70 | 9.04 | 3064 | |

| BKC-90 | 90 | 11.78 | 3900 | |

| BKC-100 | 100 | 13.15 | 4317 | |

| BKC-140 | 140 | 18.62 | 5152 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]