300 kg-Batch Desorption & Electrolysis Plant Shipped to Ghana

Dasen Mining Machinery has completed a plug-and-play desorption & electrolysis plant for a Ghanaian gold producer. The skid-mounted unit fits inside a single 40 ft HQ container and lets the client recover gold directly from loaded activated carbon—no civil work required.

| Item | Value |

| Batch capacity | 300 kg activated carbon |

| Total power | 31.74 kW |

| Operating mode | High-temperature, high-pressure (150 °C / 0.60 MPa) |

| Cycle time | 8 – 16 h per batch |

| Desorption agent | NaOH solution |

Complete Equipment Package

- Absorption columns – 0.3 m³ effective volume, 150 kg dry carbon each × 2

- Stainless-steel filter – 3 m³ h⁻¹ max flow

- Electrolytic cell – 7 anodes / 6 cathodes

- Desorption liquor tank – 1 m³ with level gauge

- Recirculation pumps – 2 m³ h⁻¹, 25 m head, 1.1 kW × 2, 150 °C rated

- Electric heater – 30 kW, adjustable on site

- Air compressor – 0.17 m³ min⁻¹ @ 0.7 MPa, 1.5 kW

- Gold-melting furnace and accessories

All piping, wiring and instruments are factory-installed; on site the customer only connects water and electricity.

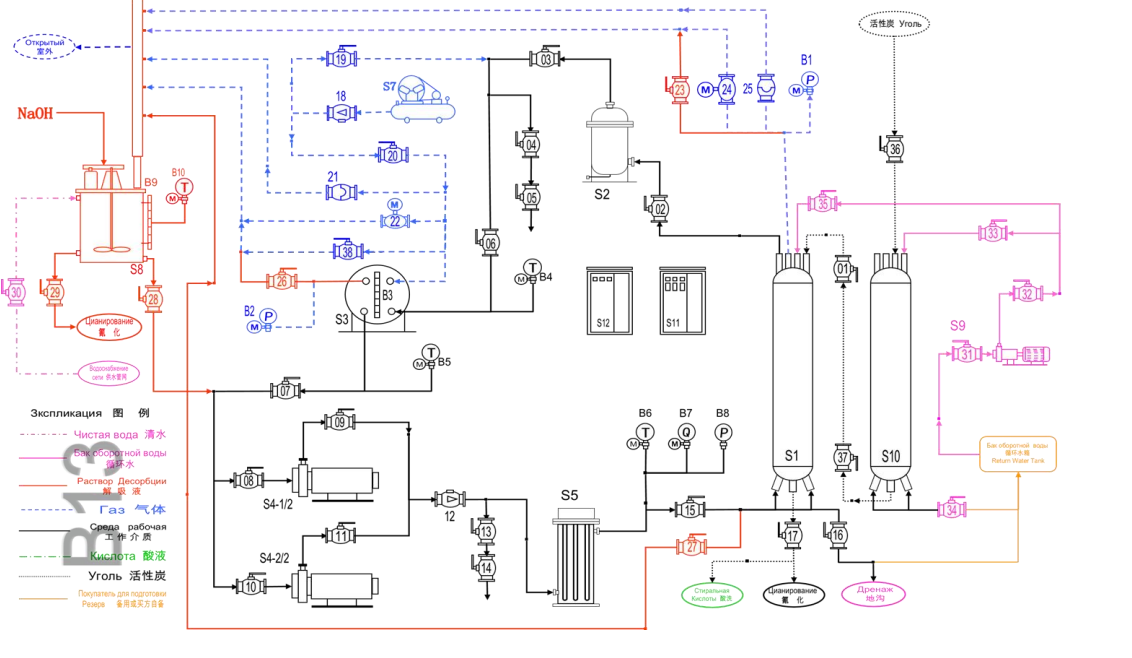

Process Flow (Simplified)

Loaded carbon → Desorption column (NaOH, 150 °C) → Pregnant solution → Electrolytic cell (gold deposition) → Smelting furnace → Dore bars

Why It Matters

• 100 % containerised: rapid installation, minimal footprint

• Energy-efficient heaters and insulated piping reduce power cost

• Proven Y13-300 process model with >95 % gold stripping efficiency

• Remote support from Dasen’s 30-year process team

Whatsapp:+86 133 1927 7356

Email:[email protected]