3 Rollers magnetic separator in Jos of Nigeria

We are pleased to announce that our latest shipment of 3-Roller Magnetic Separators has cleared customs and is currently en route to Jos. This shipment contained seven units, all of which have already been sold. We are now accepting orders for the next batch, which can be delivered to Jos in a dedicated container.

Our 3-Roller Magnetic Separator offers the following key advantages:

- High Production Capacity: Achieves a throughput of 1 to 1.3 tonnes per hour (tph).

- Simultaneous Multi-Mineral Separation: Capable of separating iron, ilmenite, and monazite concurrently.

Understanding the Nigerian market, where many operators utilize basic washing plants, there is a strong preference for high-production magnetic separators. Our model meets this demand by efficiently separating significant quantities of ilmenite and monazite in a single process.

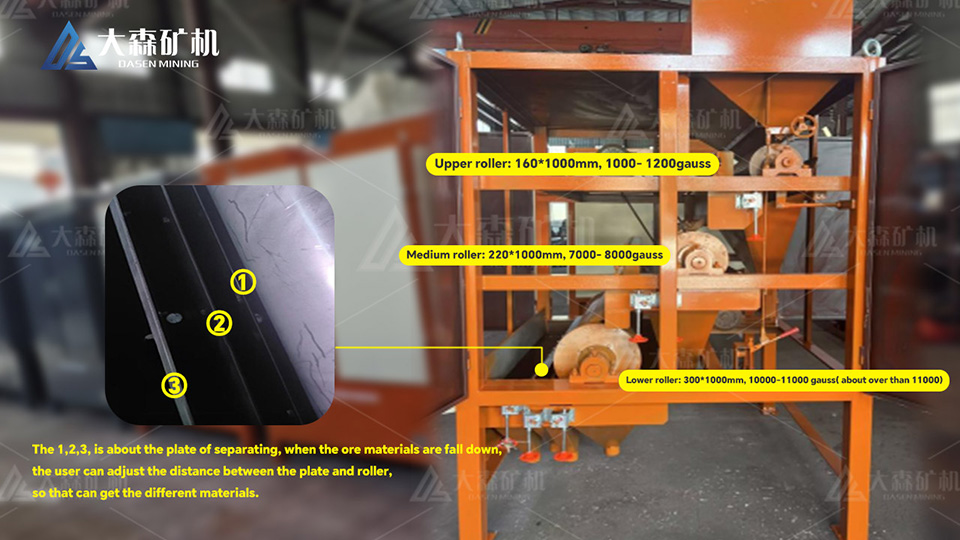

Roller Specifications:

Upper Roller: 160 x 1000 mm; Magnetic Intensity: 1,000-1,200 Gauss (G)

Medium Roller: 220 x 1000 mm; Magnetic Intensity: 7,000-8,000 G

Lower Roller: 300 x 1000 mm; Magnetic Intensity: 10,000-11,000 G (typically exceeding 11,000 G)

The high-intensity lower roller is specifically designed for the efficient recovery of monazite.

Adjustable Separation: The unit features adjustable separating plates (or splitter plates). As the ore material is processed, users can precisely modify the distance between these plates and the rollers. This allows for optimized separation and collection of the different target minerals.

If you are interested in this plant too, you can freely contact us.

Dasen Mining Machinery has been working on the magnetic ore recovery for over than 30 years. On this field, we have lots of site processing experience, we did many magnetic materials processing projects at oversea. Looking forward your inquiry.

Whatsapp:+86 133 1927 7356

Email:[email protected]