Description

Intermediate Frequency Induction Furnace: A Core Component of Electric Metal Melting

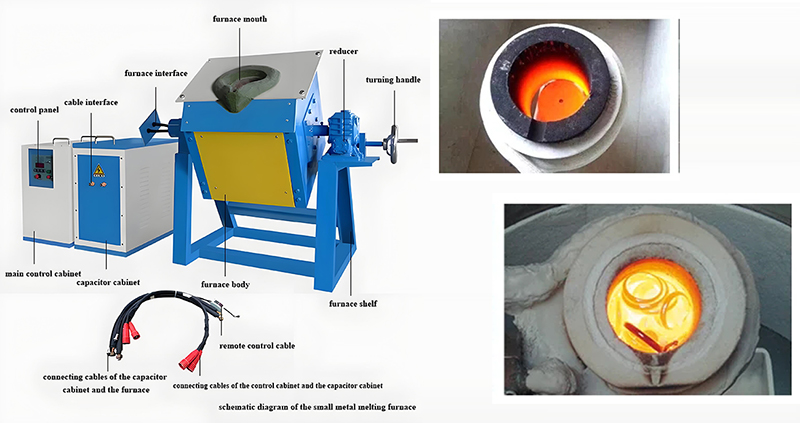

An electric metal melting furnace, specifically an intermediate frequency induction furnace, utilizes electromagnetic induction to efficiently heat and melt metals. This type of furnace is a key piece of equipment within the broader category of medium frequency furnaces. Primarily employed for preheating before forging and metal tempering, these furnaces typically operate at temperatures below 1600°C.

By converting three-phase industrial frequency electricity into single-phase medium frequency power, the electric metal melting furnace induces eddy currents within the metal, generating heat through energy dissipation. This process enables precise and controlled melting of various metals.

Medium-frequency induction furnaces are renowned for their rapid metal melting capabilities. Whether you’re working with precious metals like gold, silver, and copper, or industrial metals such as nickel, aluminum, and their alloys, or even specialty materials like glass, medium frequency induction heating offers significantly reduced melting times. For instance, precious metals and aluminum alloys typically melt within 2-6 minutes, while steel and stainless steel can be melted in just 5-10 minutes. This efficiency is achieved through the use of electromagnetic induction, which directly heats the metal, resulting in rapid and precise temperature control. Moreover, the equipment is designed for ease of installation and operation, making it an ideal choice for various industrial applications.

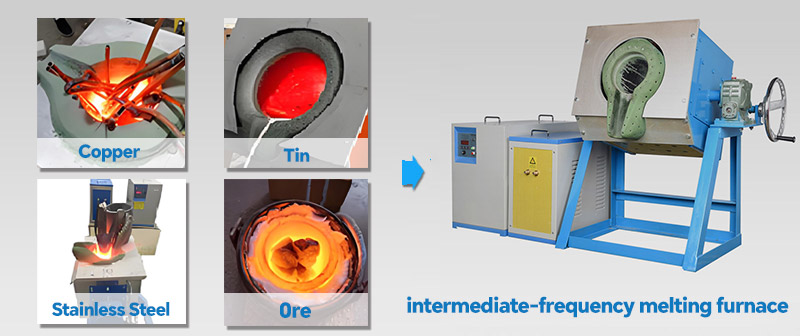

Applications of Electric Metal Melting Furnaces

Electric metal melting furnaces offer versatility across a wide range of industrial processes:

- Heat Treatment: Precise temperature control enables localized or overall quenching, annealing, tempering, and diathermy of various metals.

- Metal Forming: Facilitates hot forging, local forging, hot upsetting, and hot rolling of metal bars.

- Welding and Brazing: Ideal for joining diverse metals, including brazing, welding cemented carbide, saw blades, steel and copper pipes, and dissimilar metal combinations.

- Metal Smelting: Supports (vacuum) smelting of precious metals like gold and silver, as well as base metals such as copper, iron, and aluminum. Additionally, it’s essential for powder metallurgy sintering.

- Other Applications: Beyond core processes, electric metal melting furnaces excel in motor rotor heat fitting, bottle and toothpaste tube sealing, powder coating, and metal implant production.

Advantages of Intermediate Frequency Furnaces in Electric Metal Melting

Intermediate frequency (IF) furnaces have emerged as a preferred choice in electric metal melting due to their numerous advantages.

Operational Efficiency and Cost-Effectiveness: IF furnaces boast simple operation, rapid heating, and low energy consumption. These factors contribute to optimized melting processes and reduced labor demands. Ongoing advancements in technology, materials, and techniques have further enhanced the efficiency and effectiveness of IF furnaces, resulting in substantial social and economic benefits.

Advanced Power Conversion Technology: The integration of controllable silicon intermediate frequency devices has significantly improved furnace performance. These devices are lightweight, highly efficient, and enable fast startup. The incorporation of frequency automatic tracking systems eliminates the need for capacitor switching, ensuring optimal operation. Moreover, the adoption of IGBT frequency conversion induction heating technology has led to compact, high-performance furnaces with simplified operation and maintenance.

Enhanced Furnace Components and Materials: Innovations in furnace body and lining materials have extended crucible and furnace life. The use of high-insulating and high-strength materials around the sensor coil protects these critical components. Graphite and quartz crucibles offer superior heat transfer compared to refractory crucibles, accelerating melting times and reducing energy losses. With a maximum temperature of [Specify Temperature], IF furnaces excel in melting precious metals such as platinum, gold, and silver, as well as copper, aluminum, and other metals. The furnace’s electrical efficiency of 90-95% delivers exceptional economic returns.

Versatility and Flexibility: Unlike other smelting furnaces, IF furnaces employ electromagnetic induction heating for rapid and efficient melting. This method eliminates the need for melting metal blocks, allowing for direct processing of crushed or small materials. Consequently, IF furnaces are ideally suited for intermittent operation, frequent metal grade changes, and diverse applications, demonstrating remarkable adaptability and flexibility.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]