【Project Time】9th, March 2025

【Raw ore】Monazite

【Capacity】1TPH

【Process 】Magnetic process

【Country】Madagascar

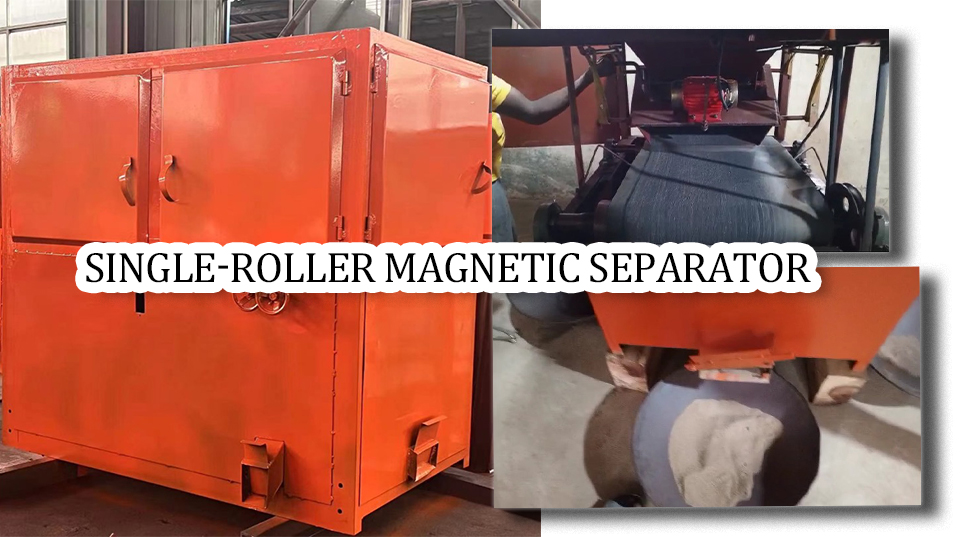

【Equipment】Single-roller magnetic separator

In April this year, an Indian customer who is engaged in rare earth mining in Madagascar contacted us. This customer is a friend of one of our previous customers from Nigeria. After experiencing our high-quality equipment in processing magnetic ores and our professional service in the Nigerian market, this customer decided to entrust us with the monazite magnetic seperator.

The main product of this customer is monazite, and the separation of monazite requires a magnetic field strength of more than 7000 gauss. The customer’s raw ore has a high iron content, a large processing volume, and the customer doesn’t have a large amount of capital.

The following picture shows the customer’s raw ore.

We proposed a solution to the customer and suggested that he choose our single-roll magnetic separator. The magnetic field strength of this equipment is as high as 9000 gauss, and it can separate all magnetic minerals at one time. The minerals can be divided into iron, ilmenite + monazite, and non-magnetic minerals (zircon, tin). On this basis, the customer first used the single-roll magnetic separator to collect all the magnetic ores. Later, the customer rented our enhanced three-disc magnetic separator from a friend and carried out the concentration of ilmenite and monazite in the three-disc magnetic separator. This not only meets the requirements of processing capacity but also ensures the grade of the concentrate.

The following picture shows our single-roll magnetic separator.

The customer is very satisfied with this economical and efficient solution.

The advantages of Dasen Mining:

The single-roll magnetic separator we offer has a high cost-performance ratio. It can collect all magnetic ores at one time. When used in combination with the three-disc magnetic separator for concentration, it can achieve the best results.

Magnetic separators with three discs are capable of separating magnetic minerals. It has a large processing volume and a high concentrate grade, making it the first choice for the concentration of many associated magnetic ores.

Whatsapp:+86 133 1927 7356

Email:[email protected]