【Project Time】20th, May 2020

【Raw ore】Rock gold ore

【Capacity】400Tons

【Process 】Leaching + Zinc powder replacement

【Recovery Rate】over than 90%

【Country】Burundi

【Equipment】 The all materials of pit leaching + the whole zinc powder replacement systerm

The customer is from Russia, they are planning to do the gold leaching in Burundi. They wanted to use the gold pit leaching + zinc replacement systerm plant.

Their gold ore is 4ppm, also is oxide gold. There is many silver in raw ore, so the customer choose to use the zinc powder replacement systerm to recovery.

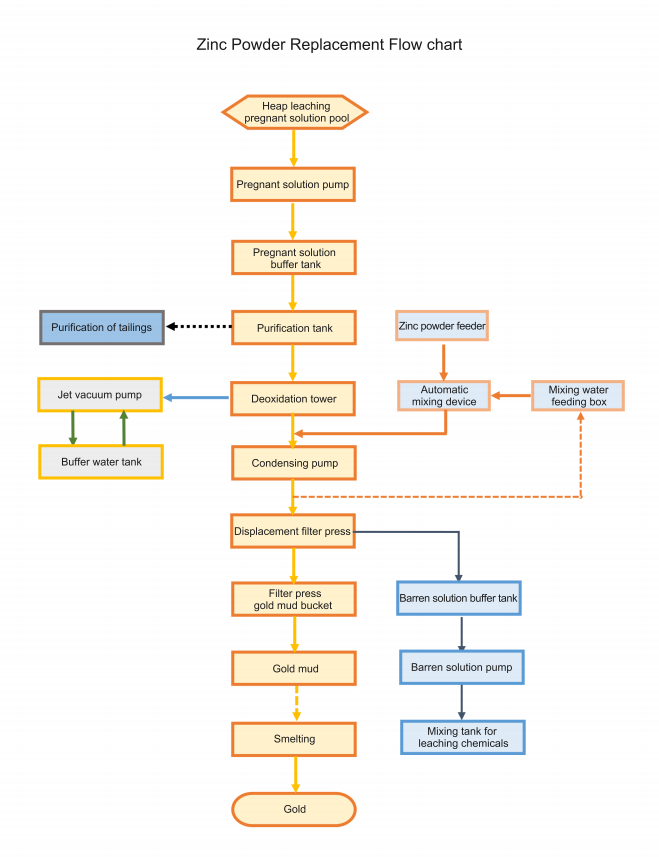

The above pictures are about the zinc powder systerm replacement, it including:

Barren solution pump/Pregnant solution pump/Purification tank/Deoxygenation column

Jet vacuum pump unit/Condensation pump/Displacement filter press/Screw zinc powder feeder

Zinc powder automatic mixing device/Zinc powder mixed feed water tank.

This whole systerm is closed circle systerm, the water after zinc powder replacement systerm can be used again.

The zinc powder replacement process extracts gold from cyanide-containing solutions through deoxygenation and the addition of zinc powder, which precipitates the gold. Deoxygenation, typically using a vacuum tower, removes dissolved oxygen harmful to the reaction. Precise zinc powder addition, often automated, ensures efficient gold precipitation into gold mud, which is then processed (e.g., using a filter press as in their line) for smelting.

This plant was delivered out from our factory on Jan of 2020, but the plant was officially started on the April of 2020. We offered to customer the remote guiding on this. The customer had his engineer on site, that engineer finished Gold Pit Leaching process and zinc replacement systerm based on our remote technique support.

Whatsapp:+86 133 1927 7356

Email:[email protected]