【Project Time】20th, March 2023

【Raw ore】Rock gold ore

【Capacity】10TPD

【Process 】Cyanidation process

【Country】Zambia

【Equipment】10TPD Container Type Portable Gold CIL Plant

In February this year, an old customer of ours from Zambia purchased a new mine. Before taking over the mine, the previous mine owner used integrated gravity separation equipment to extract Oxidized rock gold.

The following pictures are of the customer’s new mining area.

The following pictures are of the previous mine owner’s gold gravity separator equipment.

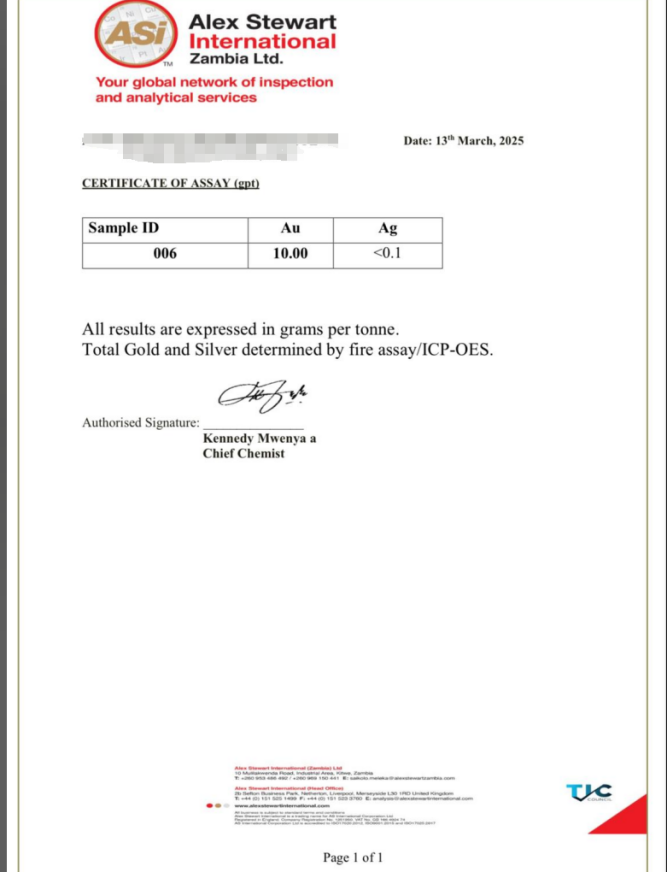

Due to the large undulation of the terrain in the mining area, the previous mine owner’s gravity separation equipment was suitable for this kind of terrain. However, after our customer completed the exploration work of the mining area and obtained the elemental analysis report of the minerals, it was determined that the minerals in the new mining area had a high degree of oxidation, and the grade of the oxidized ore was also high after drilling, making it more suitable for another method.

After our customer completed the exploration of the mining area and conducted a full elemental analysis report on the materials, it was determined that the raw ore had a high degree of oxidation. After drilling, it was found that the grade of the deep ore was relatively high. This is a gold-rich mine. Considering that the customer’s minerals contain a large amount of visible gold, which can even be manually selected (but the efficiency is too low), we decided to customize a set of process lines for the customer. Through comprehensive analysis, it is more suitable to use the cyanidation method for gold extraction. The gravity separation equipment is not suitable, so a 10-ton container cyanidation process is selected for small scale cip gold processing plant in the early stage.

The following picture is the new elemental analysis report made by the mine owner.

Why Choose a Portable Cyanidation Plant?

We chose Dasen’s 10 TPD small scale cip gold processing plant, which is portable. The equipment is installed and debugged before leaving the factory and can be directly used upon arrival at the mine site. The recovery rate of Dasen’s 10-ton container cyanidation process is over 90%, mainly targeting oxidized gold, and the leaching rate is over 85%. In order to select gold grains, we will add several mercury plates after the ball mill in the ore grinding system to collect the visible gold in the ore pulp.

The customer was very satisfied with this solution. Combining with the reagent and activated carbon samples we sent to him before, he conducted a cyanidation experiment on the minerals, and the recovery rate was as high as over 95%.

After our container equipment was installed, we received feedback from the customer. After the container cyanidation process started operation, he only needed about one month to recover all the costs, and every day after that would bring pure profit.

Whatsapp:+86 133 1927 7356

Email:[email protected]