About us

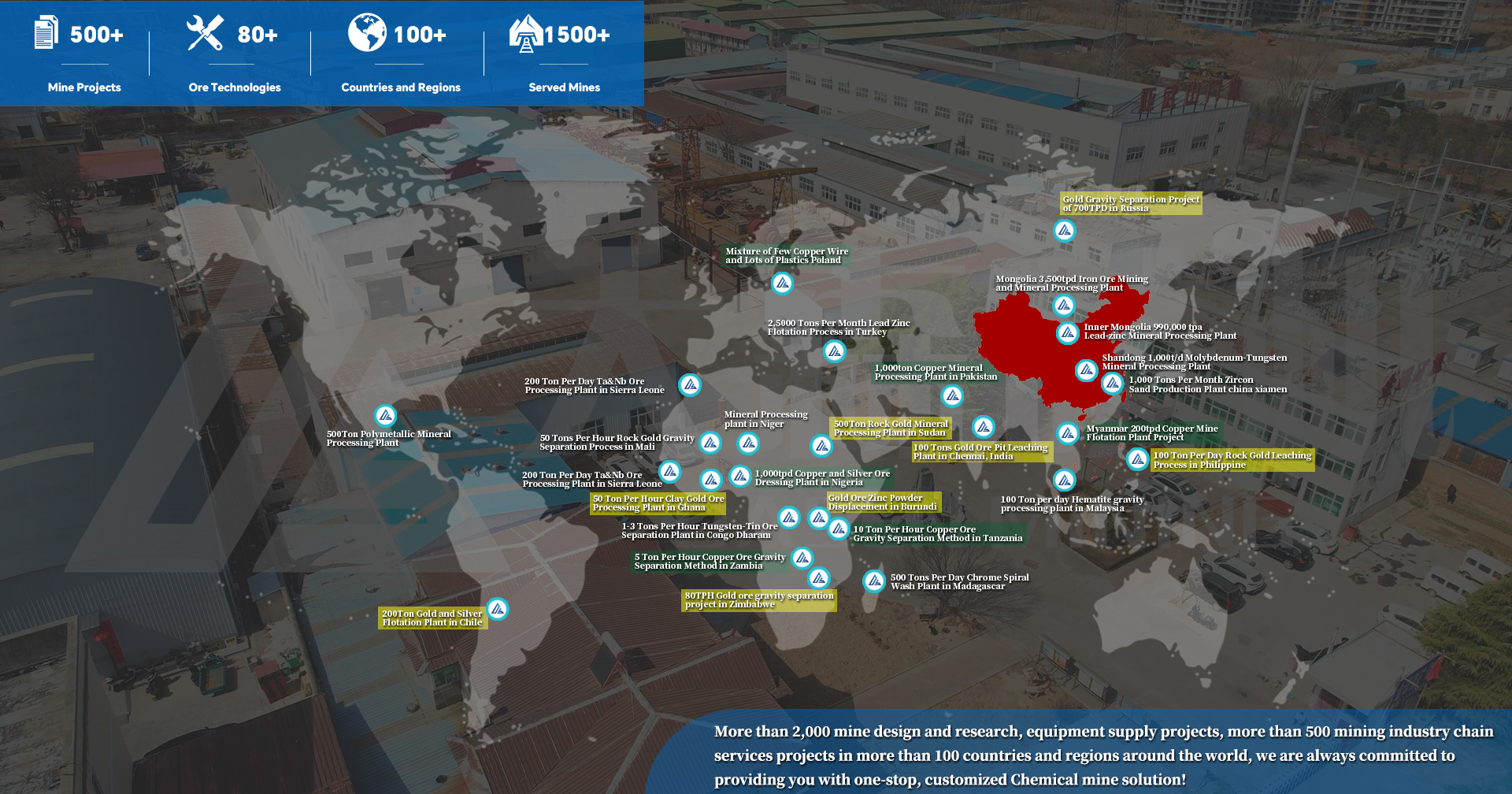

Xi’an Dasen Mining Machinery& Equipment Co.,ltd is a professional manufacturer of mineral separation equipment for gold, copper, lead-zinc, chrome, tin, tantalum, niobium, and other non–metallic minerals including quartz, zircon, barites, etc. After 30+ years of innovation and development, we can undertake from 10TPD-3000TPD separation plant, especially gold ore cyanide leaching plant and gold ore mobile trommel plant, gold/copper/lead-zinc/barite, etc flotation plant, chrome/tin/columbite/zircon sand, etc gravity&magnetic separation plant.

DASEN MINING is a comprehensive company that includes mineral analyzing, sample testing, mineral sorting research, processing line design, proper model selection, machine installation, commissioning, technical training, and so on. Our Technical Design Department consists of 18 professional and experienced technical workers including 60 senior engineers and 50+ senior technicians.

DASEN MINING provides EPC/TURN-KEY service for mineral gravity/flotation processing, cyanidation processing line, etc which also includes experiment and production operations, etc full range, and one-stop mineral beneficiation service… Our proven technologies and experience permit us to provide our clients with the world’s most competitive beneficiation plants and equipment.

DASEN MINING is obedience to the policy “QUALITY, INNOVATION, PASSION”. Abide by the business philosophy of “advanced technology, win-win benefits” and provide customers with efficient and practical services.

DasenMining’s Services

Comprehensive Research & Testing Facility

The DasenMining Mineral Dressing Research Institute spans 2,660 square meters and serves as a comprehensive hub for mineral processing, beneficiation, and metallurgical research. It integrates cutting-edge equipment, pilot-scale plants, and expert personnel to support innovation in the mining industry.

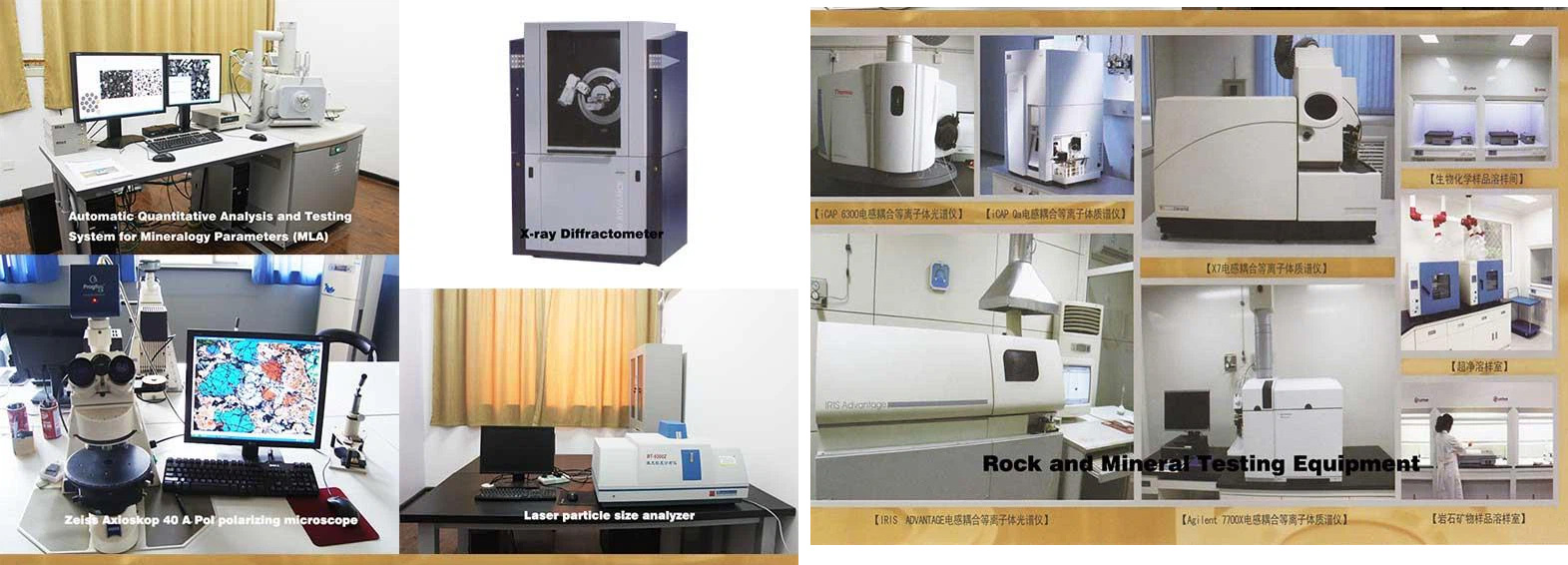

Crude Ore Properties Determination Zone

- FEI Automated Mineral Analyzer

- Bruker D8 ADVANCE X-ray Diffractometer

- Zeiss Axioskop 40 Microscope

- Laser Particle Size Analyzer

Analytical Testing Center

- Hitachi Z-2300/Z-2700 Spectrometers

- Thermo IRIS ADV ICP-OES

- Thermo iCAP Qc ICP-MS

- ETHOS1 Microwave Digestion System

Mineral Dressing Laboratory

- Flotation Cells

- Gravity & Magnetic Separation

- Chemical Beneficiation Apparatus

Metallurgical Testing Lab

- Resistance & Muffle Furnaces

- Rotary Kilns

- Leaching Columns

Pilot-Scale Testing Base

- 150 m² continuous beneficiation workshop

- Crushers, Mills, Hydrometallurgical Equipment

Research & Project Output

Research & Project Output

Over the years, the institute has filed 7 patents and achieved breakthroughs in:

- Vanadium ore mechanical dressing

- Titanium-molybdenum composite processing

- Carbon particle recovery from tailings

Representative Projects

-

- Qianjiaping Vanadium Ore Project

- Tibet Copper-Gold Studies

- Gasi Mine (Laos), Bedoka (Chile), Yaohuogou (Shaanxi)

- Luonan Hengfeng Gold Plant

The lab is a key provincial resource for comprehensive utilization of mineral resources, including low-grade and associated ores. It aims to maximize economic and sustainable recovery of valuable minerals while advancing green mining practices.

Proposed Laboratory Layout

[A] Crude Ore Properties Lab

[B] Analytical Testing Center

[C] Dressing Test Laboratory

– Flotation Cells

– Gravity Separation

– Magnetic Separation

[D] Metallurgical Testing Lab

– Furnaces

– Leaching Columns

[E] Pilot Test Workshop

– Crushers, Mills, Rotary Kiln

– Leaching Irrigation Systems

[Admin & Research Offices]

Advantages of the Center

Strong Technical Expertise: The center boasts an experienced research team and advanced experimental equipment.

Rich Project Experience: Successfully implemented numerous projects involving optimization of mining and beneficiation processes and new technology development.

Comprehensive Quality Assurance System: Various certifications have been obtained, ensuring the accuracy and reliability of experimental results.

International Collaboration Platform: The partnership with Da Sen provides robust support for the center’s expansion into international markets.

Service Scope

Mining and Beneficiation Process Optimization: Tailoring beneficiation solutions for different types of minerals.

R&D for New Processes and Technologies: Continuously exploring new beneficiation technologies to improve the comprehensive utilization rate of mineral resources.

Comprehensive Utilization of Tailings: Developing efficient tailings processing technologies to achieve resource recycling.

Environmental Protection: Committed to developing green and eco-friendly beneficiation processes to minimize environmental impact.

Dasen Advantages In a Simple View

30

Years of Experience

6,000㎡

of Factory Area

50,000,000 USD

of Annual Turnover

300+

Skillful Workers