【Project Time】 March 2024 till now

【Raw ore】Gold ore

【Capacity】500 tons per day

【Process】Flotation processing

【Recovery Rate】85%

【Country】Zimbabwe

Since late 2022, DASEN MINING has been responsible for the EPC (Engineering, Procurement, and Construction) of a 500TPD gold flotation separation facility in Zimbabwe. After comprehensive trenching, sampling, and repeated metallurgical testing, flotation was confirmed as the most efficient method for processing the primary gold ore.

What is Trenching?

Trenching is a surface exploration technique used to expose mineralized zones by removing overburden. It allows geologists to analyze and sample rocks to determine the economic viability of a deposit.

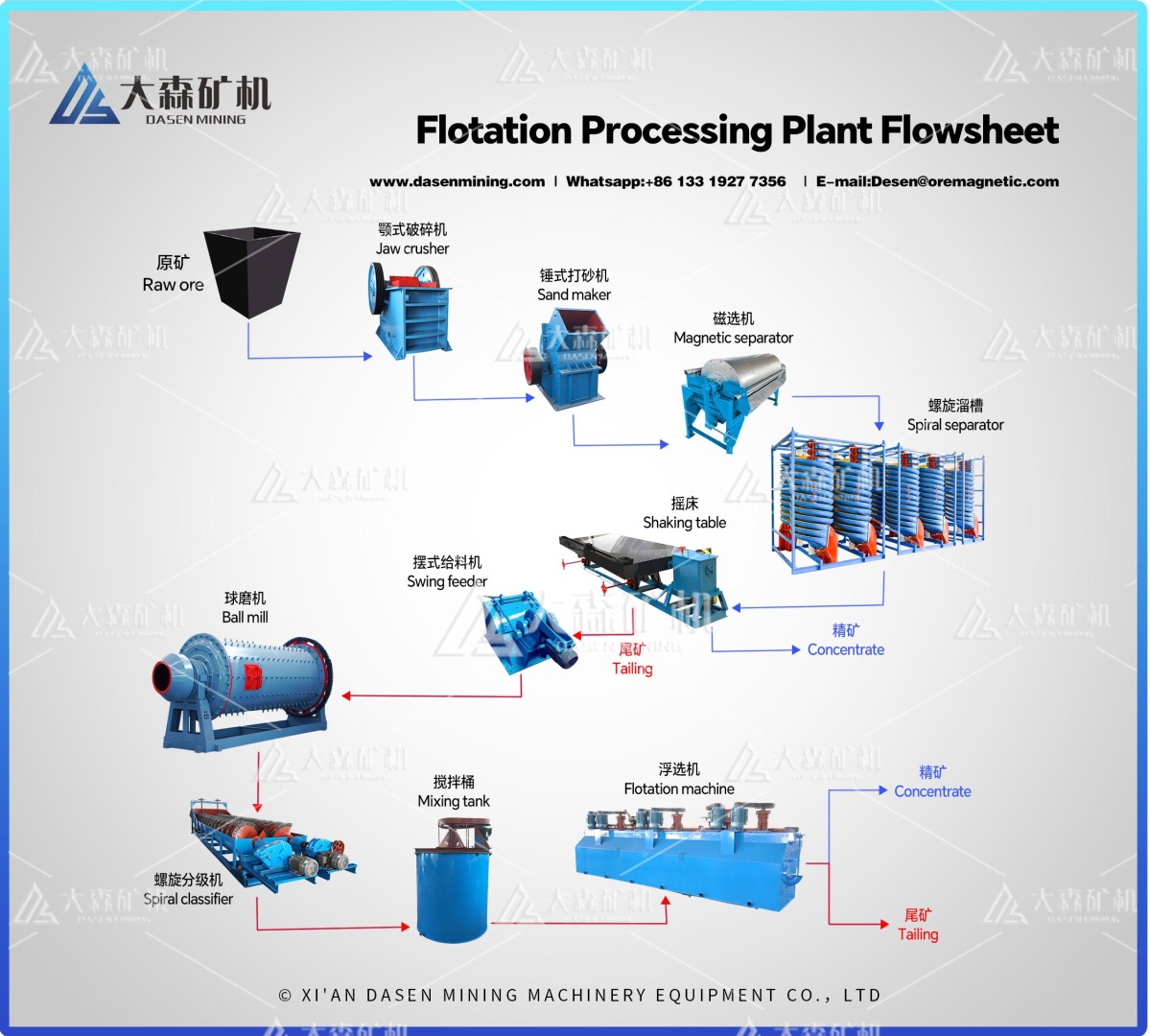

Processing Line Configuration

The complete processing plant consists of three main systems:

Crushing System

Reduces raw ore to optimal particle size for grinding.

Grinding System

Further pulverizes ore for efficient mineral liberation.

Flotation System

Separates gold from gangue to produce high-grade gold concentrate.

The final concentrate, containing approximately 100–150 ppm of gold per ton, is shipped directly to China for further refining.

Dasen mining has professional mechanical manufacturing engineers, beneficiation engineers, and a professional equipment installation team and rich practical experience,

Our services include: ore analysis, beneficiation experiment, beneficiation process design, equipment manufacturing, construction, equipment installation, commissioning, operation, and a series of on-site EPC/turn-key production technical services, etc.

Warmly welcome clients from all over the world visiting our factory in China.

Whatsapp:+86 133 1927 7356

Email:[email protected]